High precision digital sonic wave variable density calibration method

A calibration method and variable density technology, applied in earthwork drilling, measurement, wellbore/well components, etc., can solve the problem of difficulty in the accuracy of variable density logging tools, and achieve faster production debugging, high precision, and easy scale. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

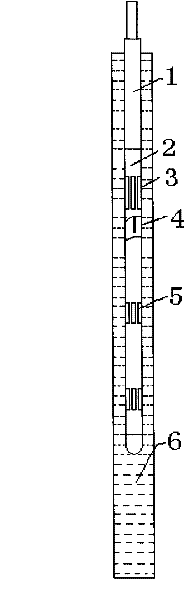

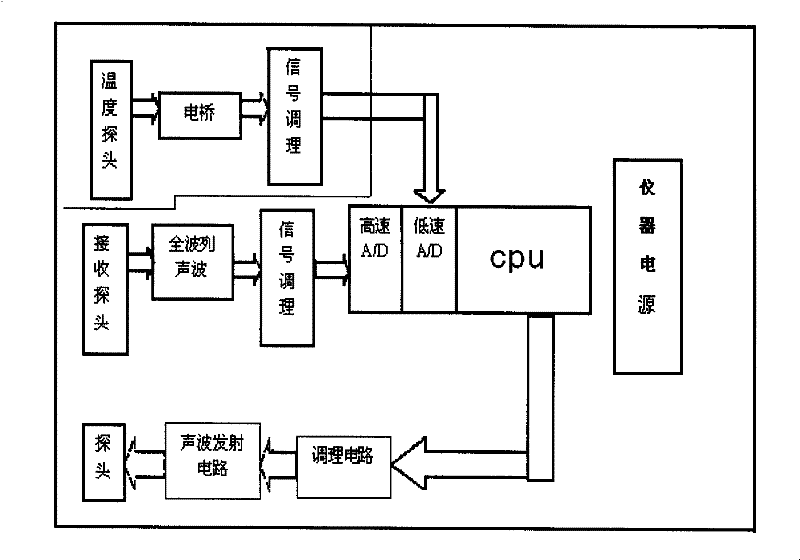

[0021] refer to figure 1 Schematic diagram of the structure of the variable density instrument in the standard scale cylinder, which includes an electronic circuit 1, a variable density sound system 2, a transmitting probe 3, a temperature probe 4, a receiving probe 5 and a standard scale cylinder 6. The scale cylinder is filled with water, the pressure in the cylinder reaches 2Mp, and the instrument does not limit the signal at the highest gain level.

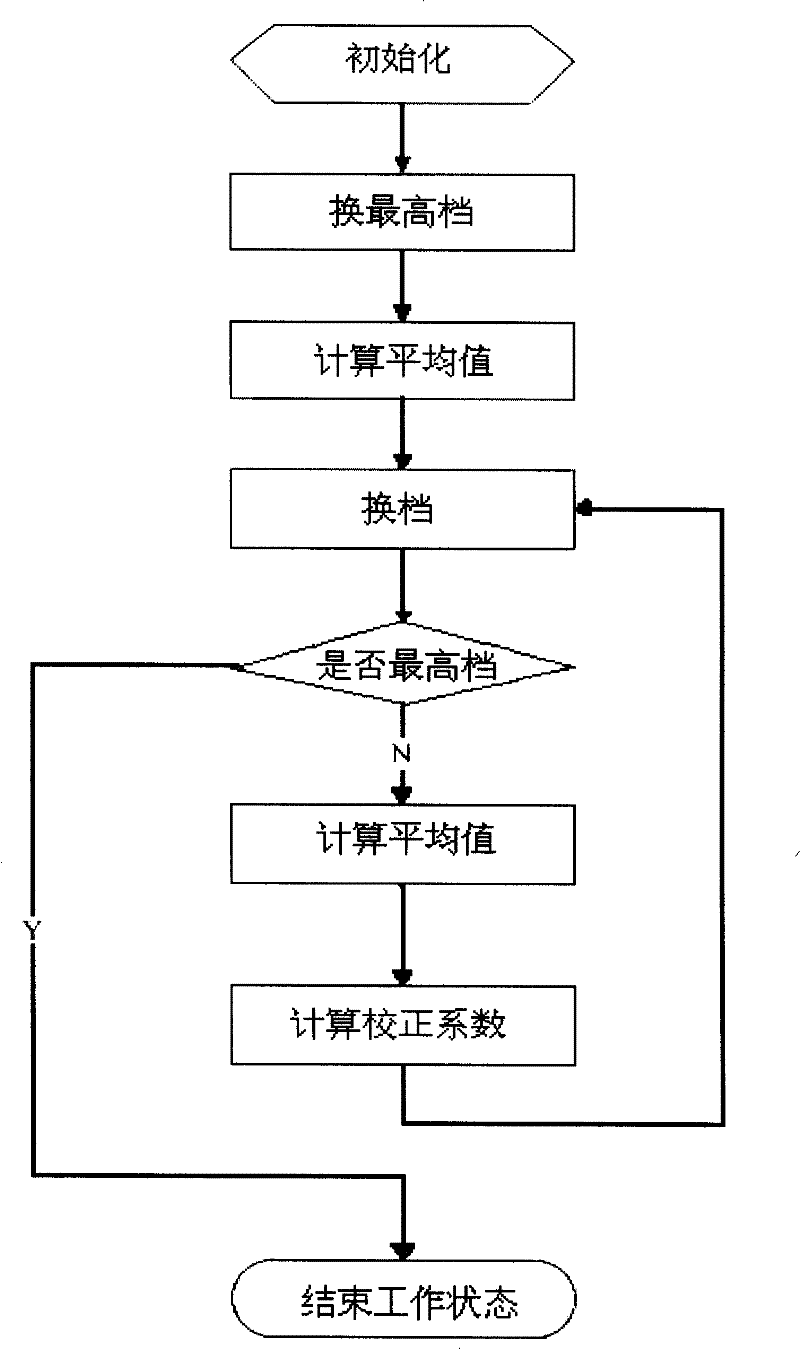

[0022] Combine below image 3 The method flowchart of the embodiment of the present invention explains in detail the implementation of the present invention in the calibration process and the well-going process

[0023] The calibration process is as follows:

[0024] 1. Power up the instrument

[0025] 2. Reset all the correction coefficients of the sound waves to 1;

[0026] 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com