Steel structure modularization construction process

A construction technology and modular technology, applied in the direction of building structure, construction, building materials processing, etc., can solve the problems of large construction volume, high cost, unreachable, etc., and achieve the reduction of high-altitude workload, high technical requirements, and easy installation fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in further detail below. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0023] A steel structure modular construction process, the construction process includes the following steps:

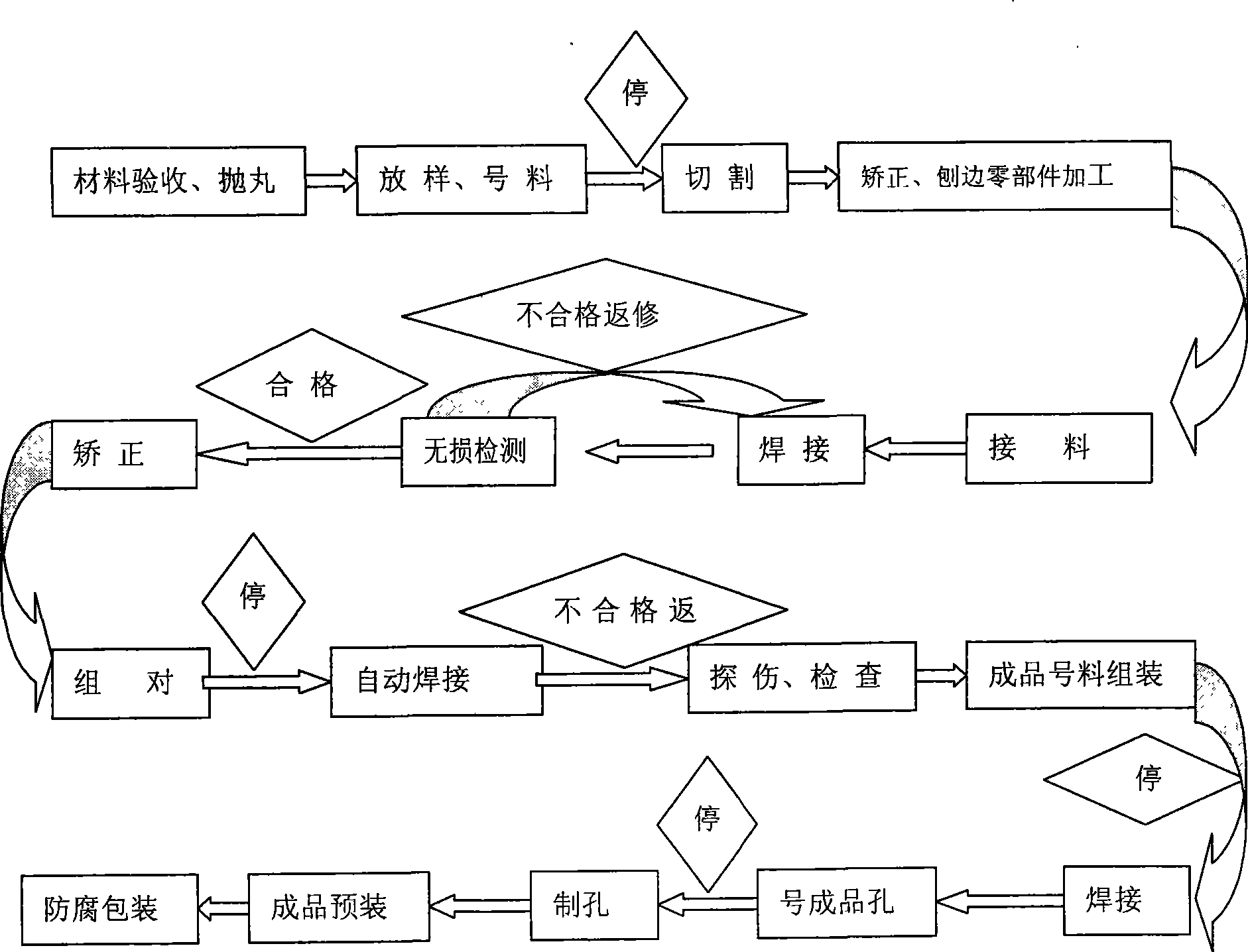

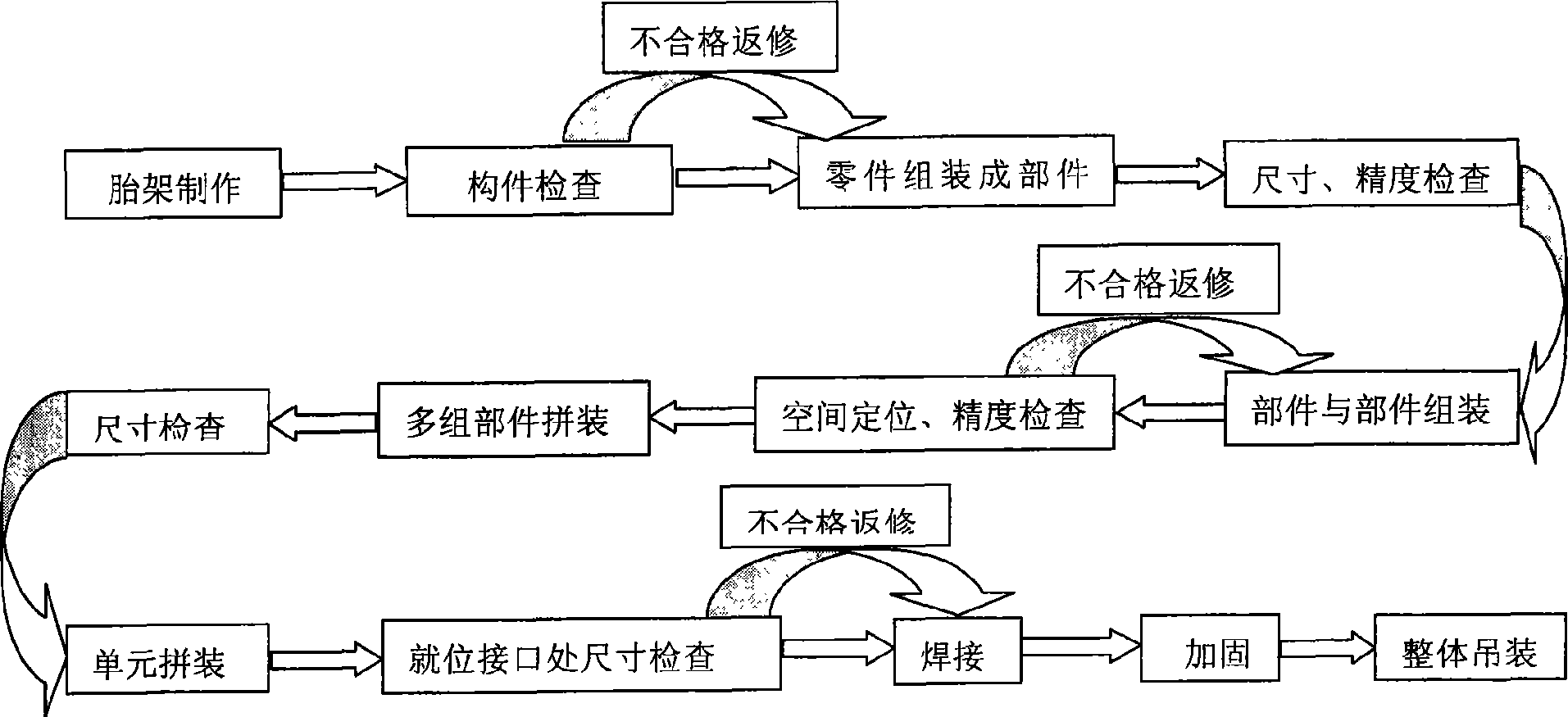

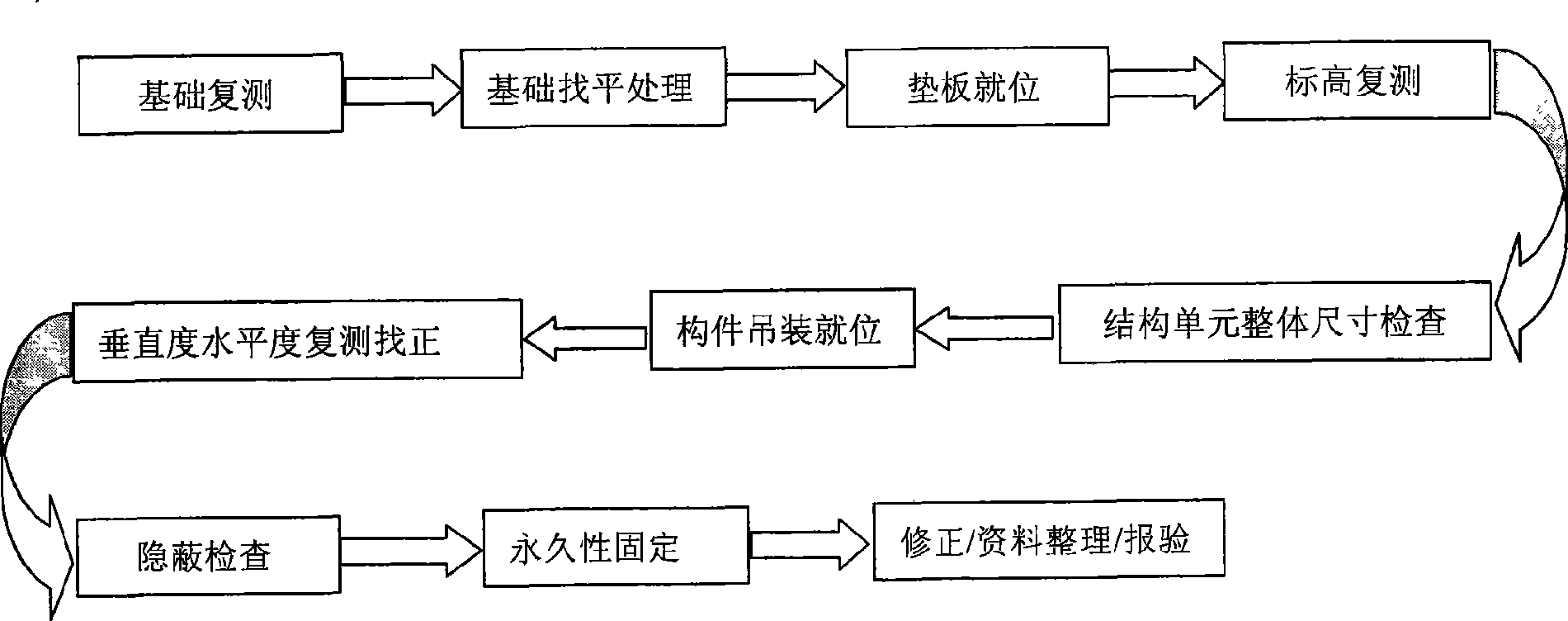

[0024] (1). The components used in the steel structure are precisely processed in the workshop. The process is: material acceptance, shot blasting; lofting, material numbering; cutting; correction, planing parts processing; material receiving; welding; non-destructive testing ; Correction; Group pairing; Automatic welding; Flaw detection, inspection; Assembly of finished product numbers; Welding; Number of finished product holes; Hole making; Finished product pre-assembly; Anti-corrosion packaging.

[0025] Its key processes include:

[0026] A. Reasonable segmentation and block, strict cutting size accuracy. The principle of scientifically and ration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com