Method for manufacturing a machine felt and machine felt

一种机制、纵向纱线的技术,应用在造纸机、造纸、非织造布等方向,能够解决横向纱线作用有限、高制造成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

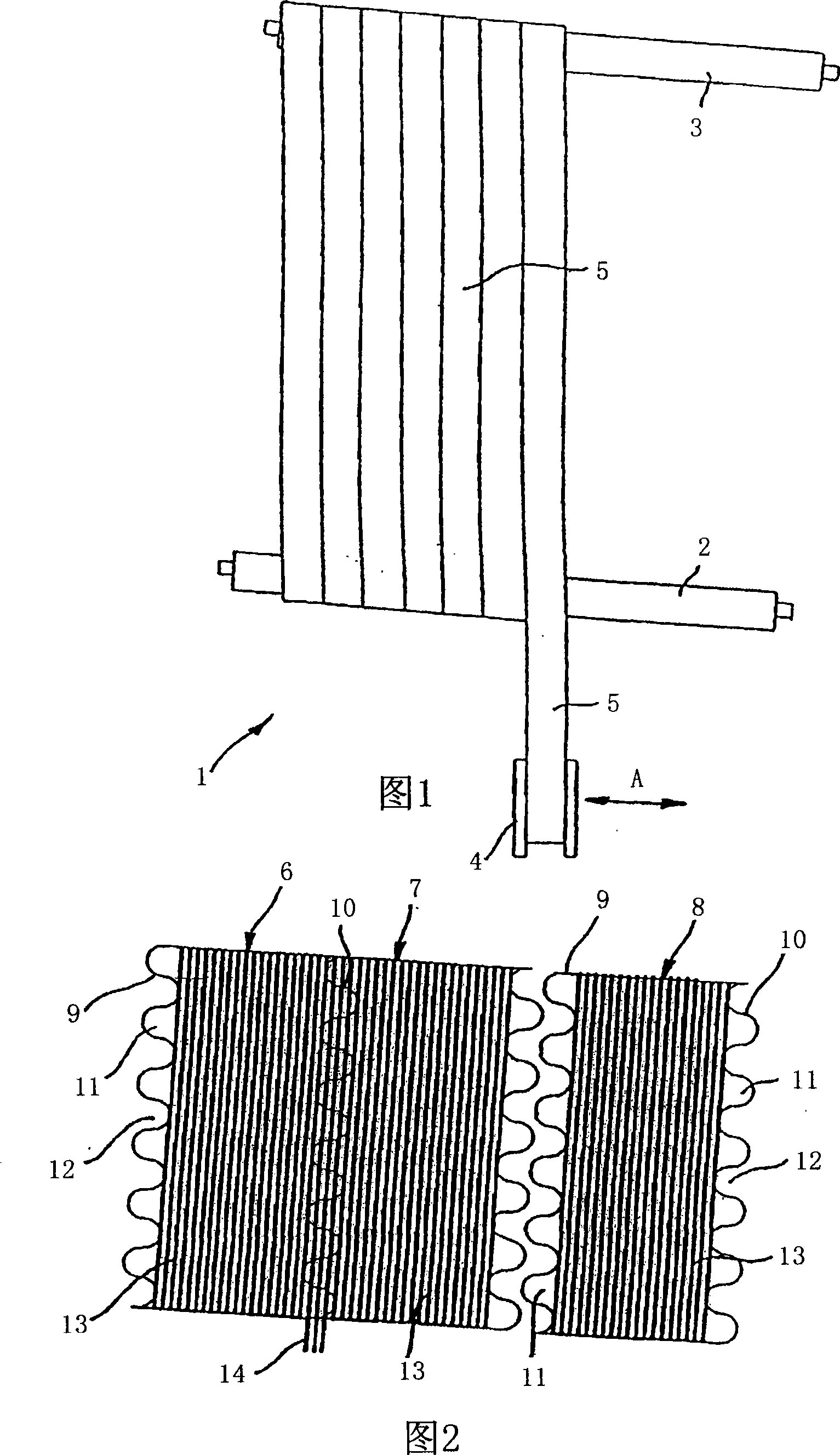

[0048] The device 1 shown in Figure 1 has two spaced apart rollers 2, 3 with parallel axes of rotation and driven in the same direction. The storage roller 4 is kept at a distance from the lower roller 2 , and the mesh belt 5 of synthetic material is wound on the storage roller 4 . When the rollers 2 , 3 are driven, the synthetic material mesh belt 5 is drawn off from the storage roller 4 and wound onto the two rollers 2 , 3 . In this case, the storage roller 4 moves in the direction of the arrow A, ie parallel to the axes of rotation of the rollers 2 , 3 . Thereby, the synthetic material mesh belt 5 is gradually wound to the right in a helical manner onto the rollers 2 , 3 . In this case, the feed of the storage rollers 4 in the direction of the arrow A is determined in such a way that the plastic mesh belts 5 abut each other with their adjacent edges. The accumulator rollers 4 are arranged at a corresponding inclination so that no skewing can occur. The winding process co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com