Method for preparing multielement micropore mineral fertilizer from silicate rock through hydrothermal chemical reaction

A technology of chemical reaction and microporous minerals, which is applied in the field of mineral fertilizer production, can solve the problems of broken soil fertility coordination balance, biological growth, and low actual utilization rate, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

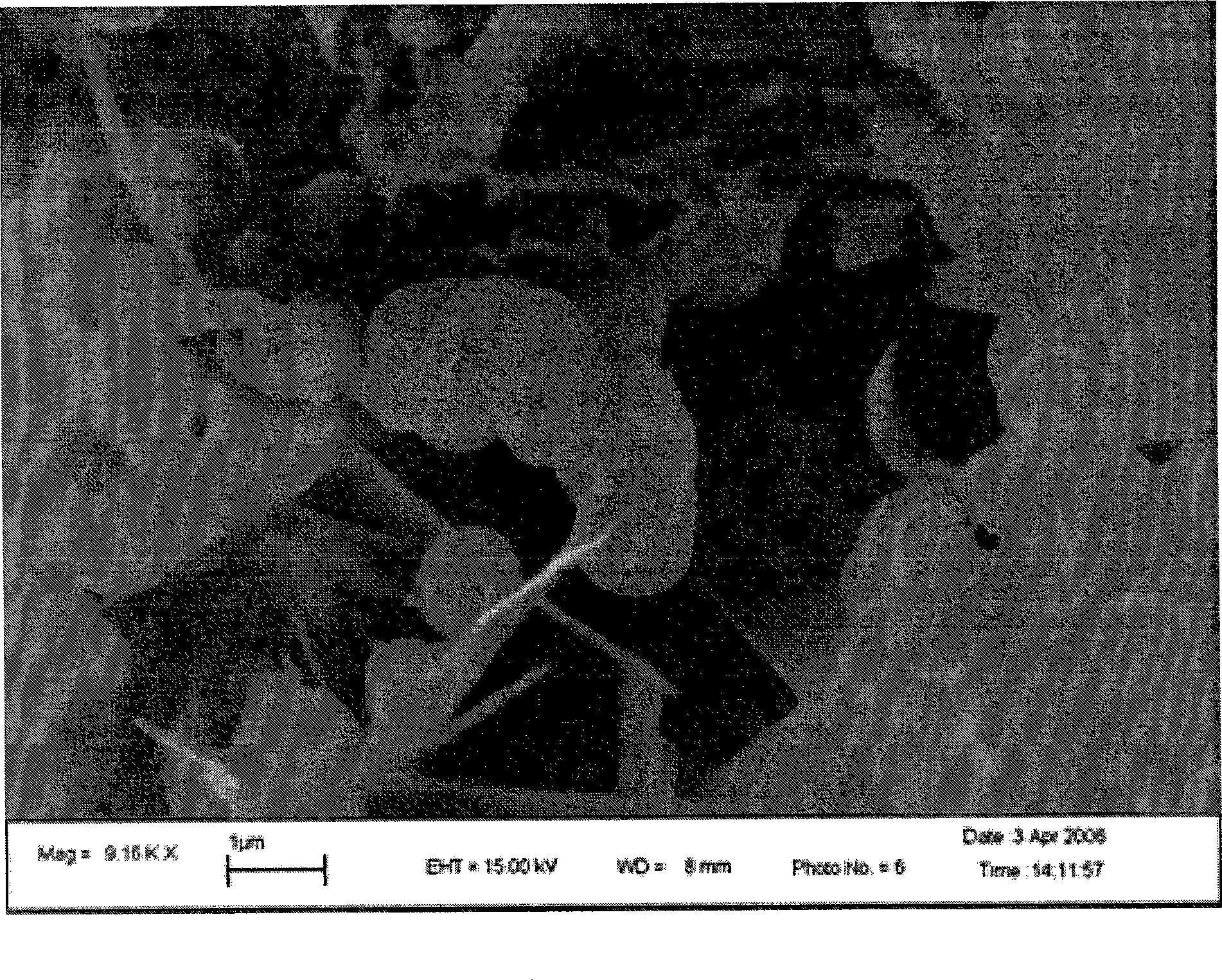

Image

Examples

preparation example Construction

[0036] In the preparation method of the present invention, the amount of water used is extremely important. Too little water cannot ensure the dissolution effect of various components, while too much water will reduce the processing capacity of materials, thereby reducing productivity. The amount of water used in the present invention is selected according to the amount of solid material, so that the solid material is in a semi-wet state. In the present invention, the amount ratio of water and solid materials, that is, the solid-to-liquid ratio, is 1:1-3, preferably 1:1.2-1.5.

[0037] In addition, the pressure in the reaction system is also important for hydrothermal reactions. In industrial production, steam can be introduced into the reaction system to keep the reaction pressure constant. Generally speaking, the higher the pressure, the more favorable the hydrothermal reaction will be. However, considering the equipment cost and the evaporation of existing water in the r...

Embodiment 1

[0048] 1) Selection of raw materials, including potassium-containing rocks and lime:

[0049] Potassium-containing silicate rock: collected from Nanshan, Miyun County, Beijing, its chemical composition (%) is as follows

[0050] SiO 2 TiO 2 AlO 3 Fe 2 o 3 +FeO MnO CaO MgO K 2 o Na 2 o P 2 o 5 Loss on ignition total 63.09 0.71 15.69 4.41 0.02 0.15 0.37 12.79 0.22 0.04 1.93 99.42

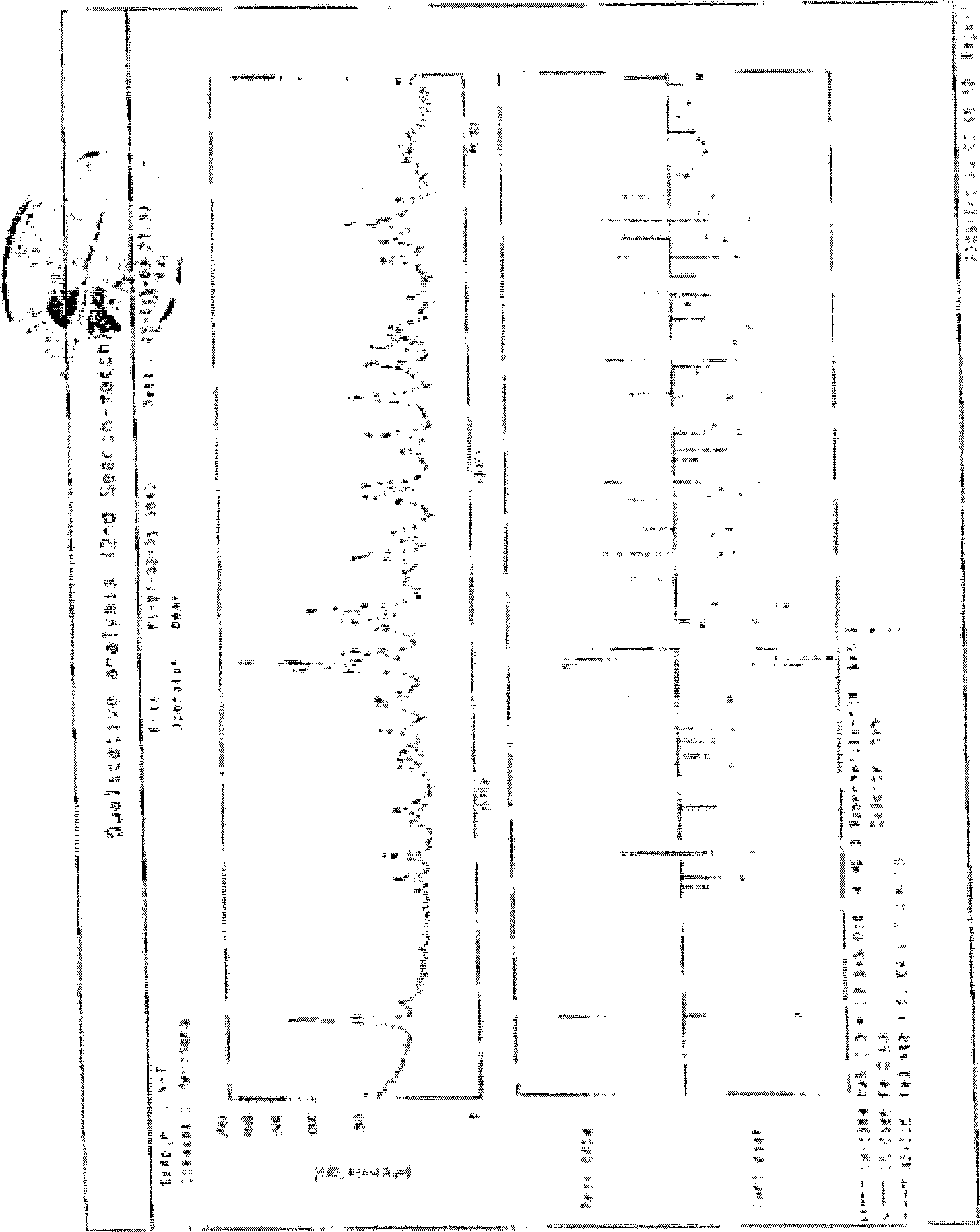

[0051] X-ray powder crystal diffraction analysis indicates that the potassium-bearing rock is mainly potassium feldspar, and the others are quartz.

[0052] Lime: Containing 97% CaO (chemically pure, Beijing Purchasing and Supply Station of Chinese Pharmaceutical Company).

[0053] 2) Production process:

[0054] (1) Crush the potassium-containing rock and lime to below 200 mesh respectively, first add 30ml of water to the plastic vessel, then add 5.000 grams of potassium-containing rock mineral powder and 5.000 grams of lime powder to th...

Embodiment 2

[0059] 1) Selection of raw materials, including potassium-containing rocks, lime and gypsum:

[0060] Potassium-containing silicate rock: collected from Nanshan, Miyun County, Beijing, its chemical composition (%) is as follows

[0061] SiO 2 TiO 2 AlO 3 Fe 2 o 3 +FeO MnO CaO MgO K 2 o Na 2 o P 2 o 5 Loss on ignition total 63.09 0.71 15.69 4.41 0.02 0.15 0.37 12.79 0.22 0.04 1.93 99.42

[0062] X-ray powder crystal diffraction analysis indicates that the potassium-bearing rock is mainly potassium feldspar, and the others are quartz.

[0063] Lime: containing 97% CaO (chemically pure, purchased from Beijing Supply Station of Chinese Pharmaceutical Company).

[0064] Gypsum: collected from the Xiazigai bentonite mining area in Xinjiang and Buxar County, it is transparent gypsum with good crystallization, heated in a laboratory oven at 120°C for 1 hour to obtain hemihydrate gypsum (CaSO 4 1 / 2H 2 O).

[0065] 2) Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com