Method for producing agricultural mineral base potassium nitrate by using potassium-rich rock

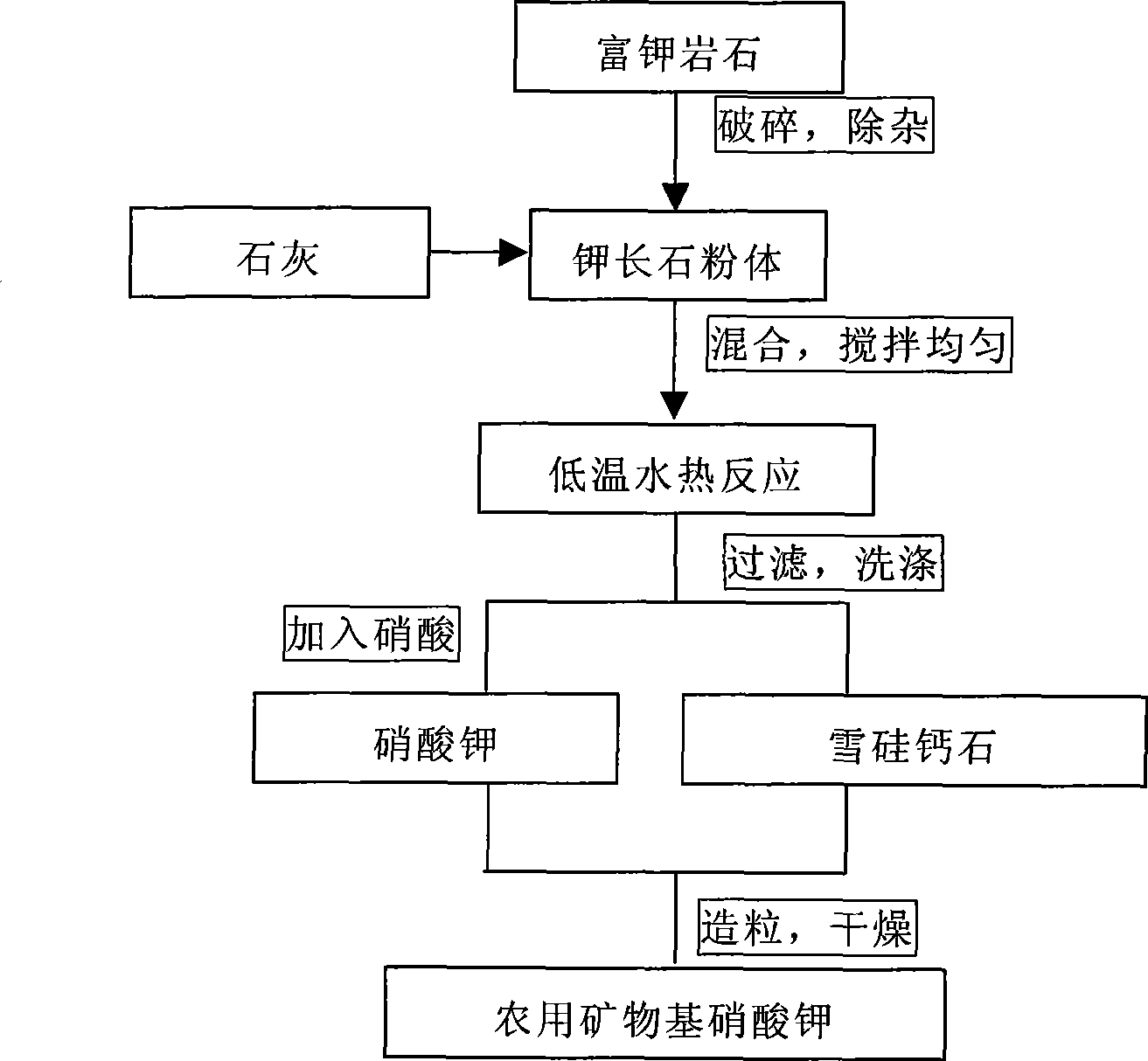

A technology of potassium-rich rock and potassium nitrate, applied in the fields of alkali metal nitrate preparation, potash fertilizer, application, etc., can solve problems such as unrealized industrial production, and achieve high-efficiency utilization and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Potassium-rich rock raw material: Muscovite syenite from a certain place in Lushi County, Henan Province, the chemical composition is as follows (%):

[0035] SiO 2 TiO 2 al 2 o 3 Fe 2 o 3 FeO MnO MgO CaO Na 2 OK 2 OP 2 o 5 Loss on ignition Total

[0036] 58.01 0.93 17.87 3.93 0.32 0.02 0.30 1.06 0.28 14.69 0.09 1.82 99.32

[0037] According to the chemical composition of the whole rock and the X-ray powder crystal diffraction analysis results, the phase composition of the muscovite syenite is: 85.5% microplagioclase, 7.6% muscovite, 2.4% titanite, 1.1% magnetite, red Iron ore 2.7%, apatite 0.2%.

[0038] The experimental process is as follows:

[0039] (1) Grind the muscovite syenite to -300 mesh>90% particle size, mix according to the mass ratio of potassium feldspar powder: lime is 1:0.83, take 300g of potassium feldspar powder, 249g of lime, press Add the water-solid mass ratio of 20:1 into the reaction kettle, and stir well;

[0040] (2) Seal...

Embodiment 2

[0046] In order to obtain a high content of KNO 3 The product, adopts the same raw material as in Example 1, the experimental process is the same as the (1) step-(5) step of Example 1, after completing the (5) step, add to the step (5) gained slurry Potassium nitrate saturated solution, till toberberberite is all adsorbed, then carry out the granulation, drying process described in step (6) identical with embodiment 1, make mineral base potassium nitrate product 636.4g. After determination, the KNO in the obtained product 3 The content is 58.6% (mass percentage).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com