Multi-stage aerobic and anoxic coupling bioreactor and sewage disposal method

A bioreactor, super-aerobic technology, applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

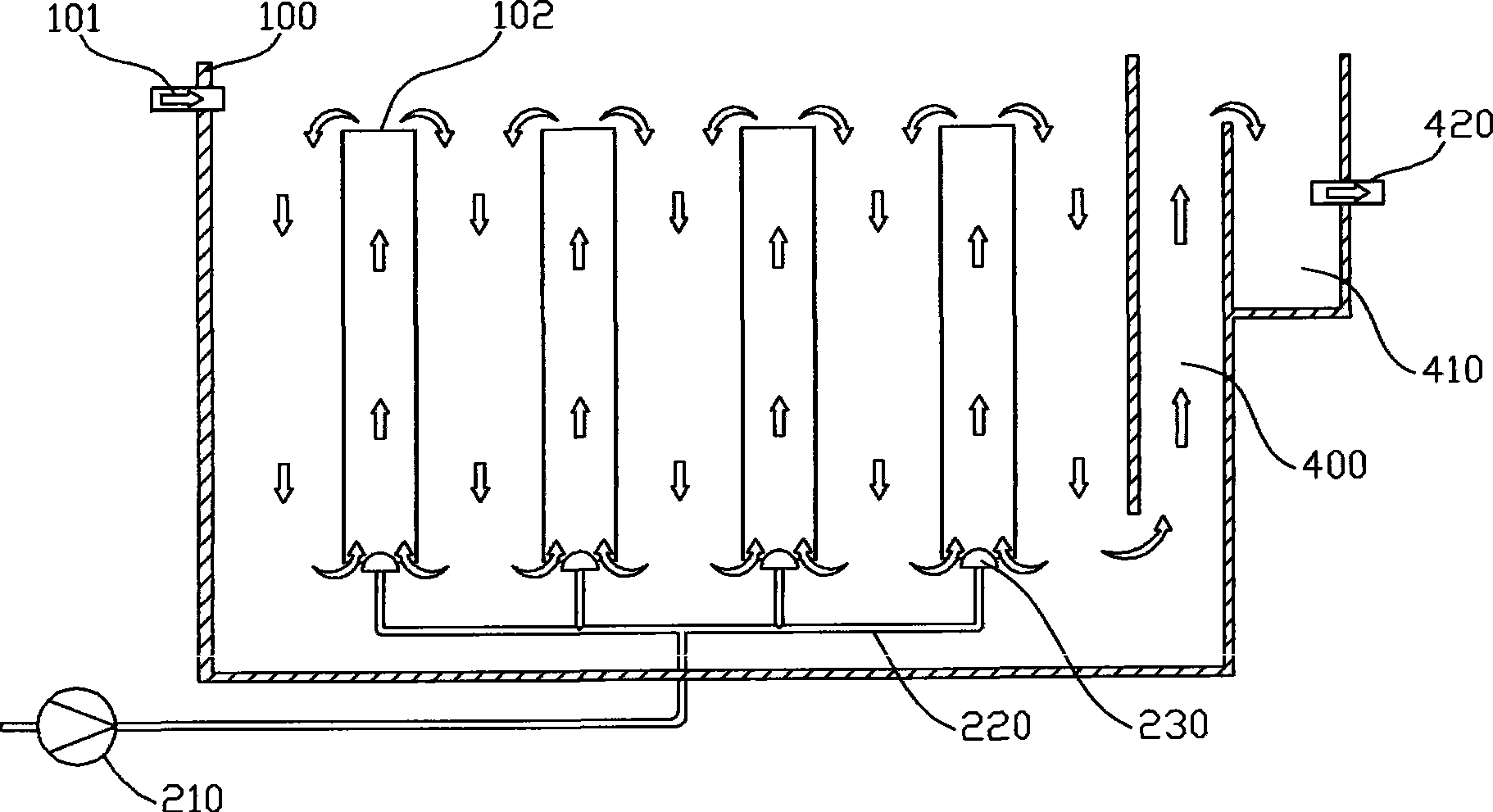

[0023] Embodiment 1: as figure 1 shown. The incoming water is domestic sewage, the flow rate is 0.5 cubic meters per hour, and the incoming water COD is between 200-380mg / L; the length, width, and height of the bioreactor are 2.5m, 0.6m, and 1.2m respectively, and the distribution diameter in the bioreactor is 0.25m There are 6 PVC diversion barrels 102 in total, and the inside and outside of the diversion barrels are filled with mesh honeycomb biological fillers, and a waterfall gas head with a diameter of 0.2m is installed under each diversion barrel. A proper amount of activated sludge was added when the operation was started, and after 15 days of domestication, the effluent COD was 15mg / L.

Embodiment 2

[0024] Embodiment 2: as figure 2 shown. The inner diameter of the bioreactor is 0.75m and the outer diameter is 1.0m. There are 8 PVC diversion barrels 102 with a diameter of 0.25m distributed in the bioreactor. Other experimental conditions are the same as in Example 1. After 15 days of acclimatization, the effluent COD was 18mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com