Device and method for cleaning through-printing forme and screen process press with the device

A screen printing machine and missing printing technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as missing printing plate pollution, and achieve the effects of improving printing quality, convenient use, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

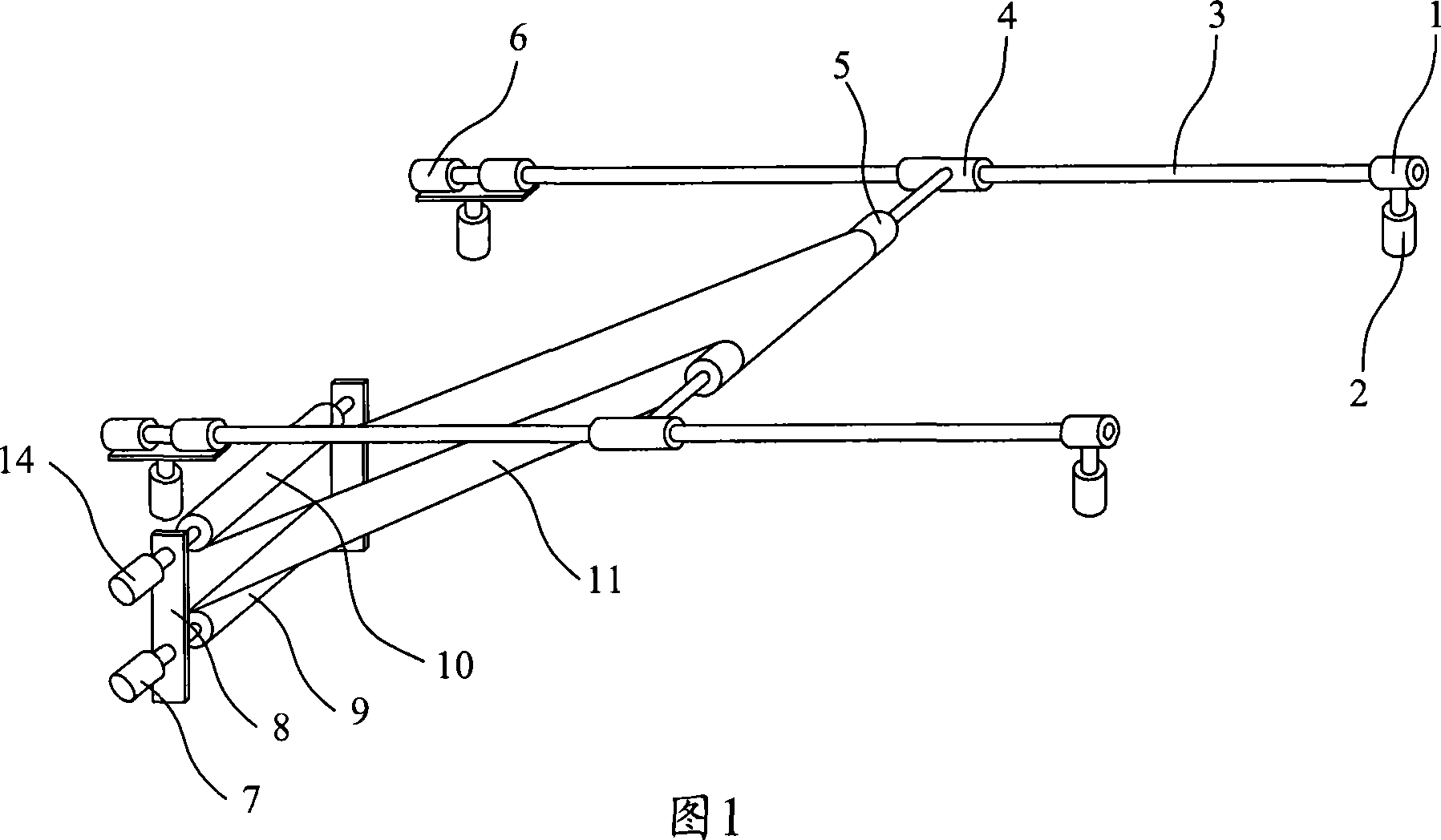

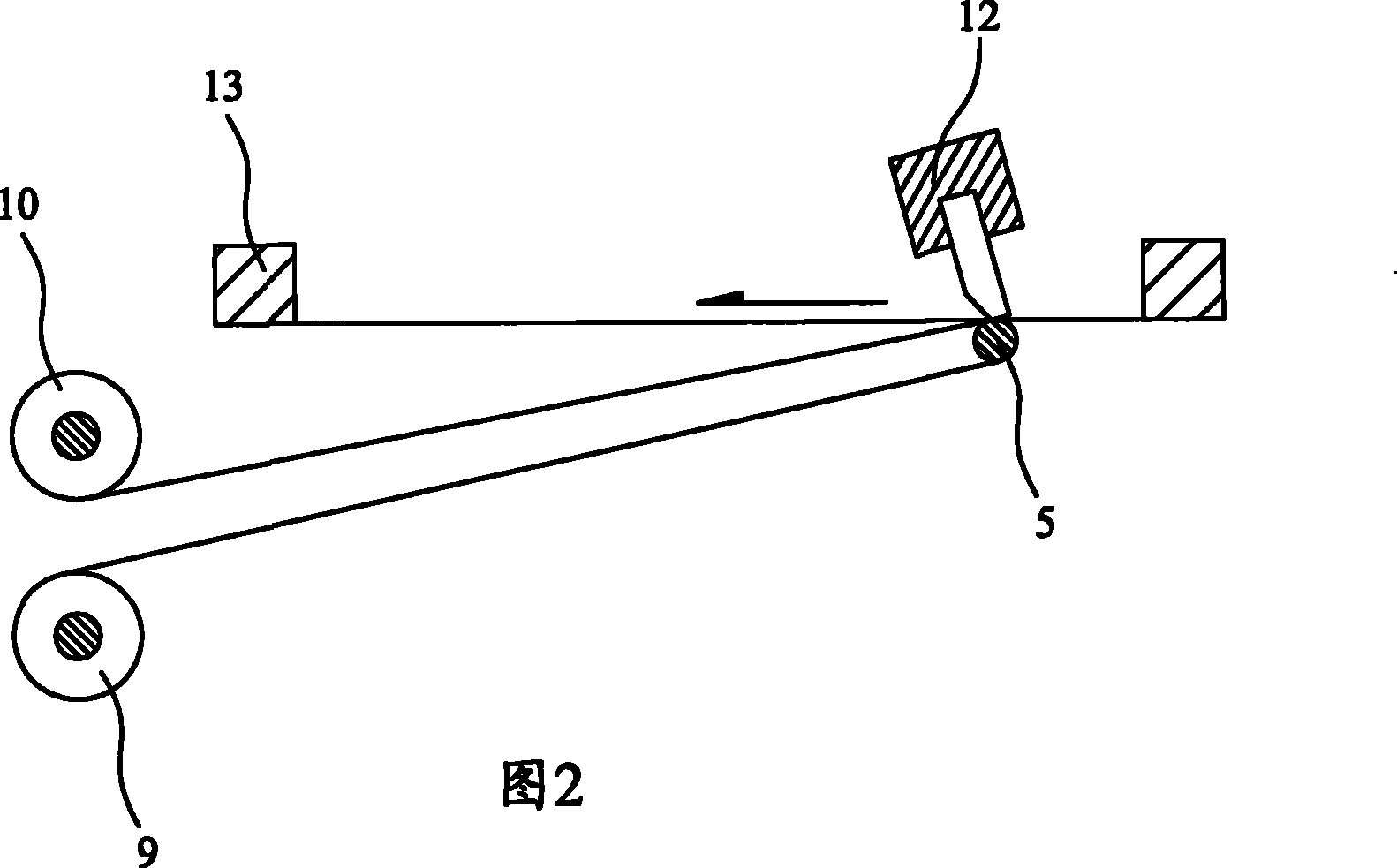

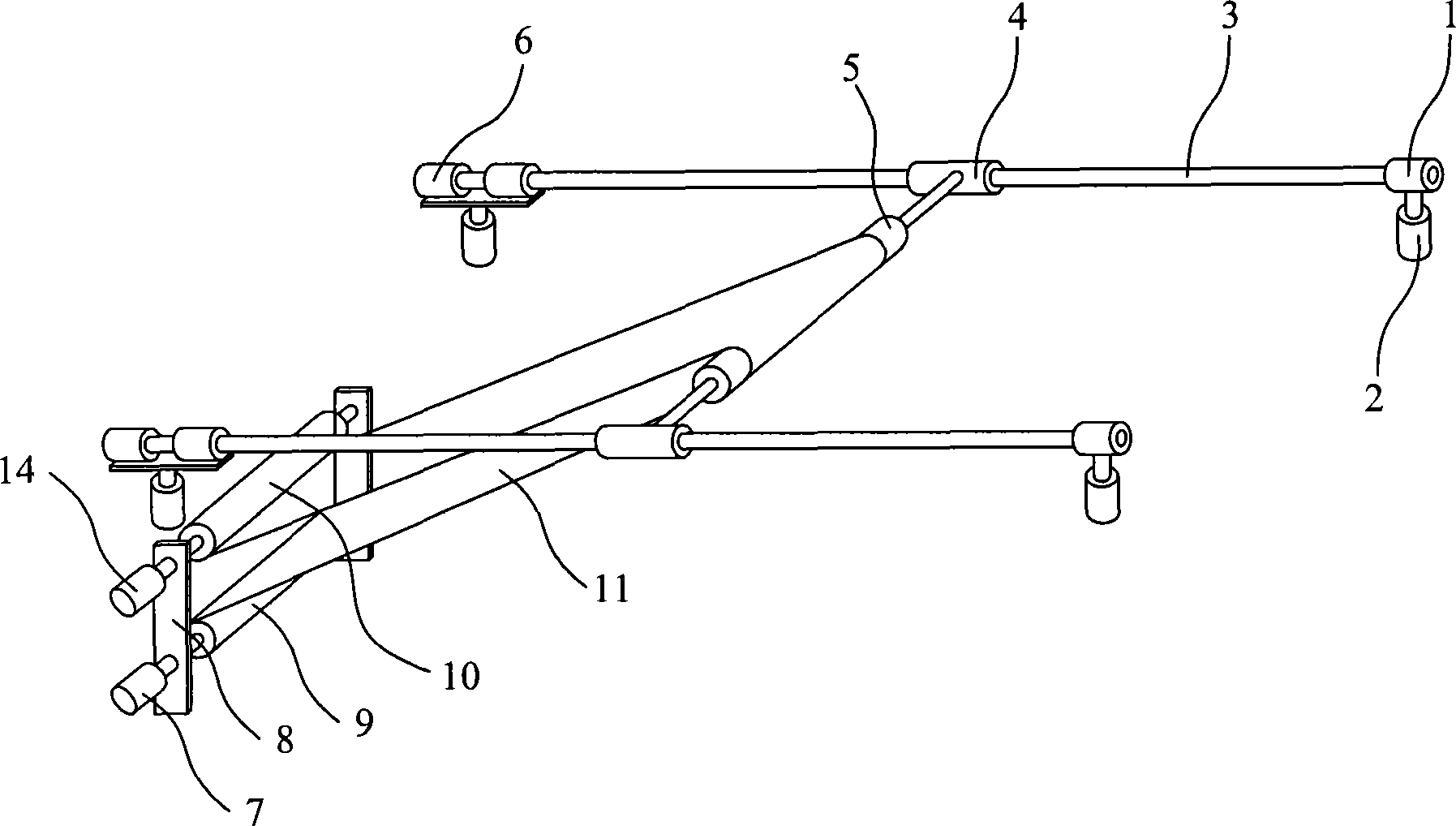

[0023] Such as figure 1 , The device for cleaning the missing printing plate of the present invention includes: a cleaning roller 5, a mechanism for driving and adjusting the cleaning roller, a release roller 10, a recovery roller 9, a driving motor 7 for driving the recovery roller, an adhesive belt 11 and a force balance mechanism. An adhesive tape 11 is wound on the release roller 10 and from there runs around the cleaning roller 5 and is finally attached to the recovery roller 9 . In this embodiment, in order to reduce the force required to drive the adhesive tape, the adhesive tape 11 is set to be sticky on one side, its non-adhesive surface is in contact with the cleaning roller 5 and walks around the cleaning roller 5, while its sticky side is ready to stick The stencil. The mechanism for driving and adjusting the cleaning roller includes: a screw bearing 1 , a screw lifting cylinder 2 , a driving screw 3 , a driving nut 4 and a driving motor 6 for the screw. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com