Suction oil filter with bypass

An oil suction filter and bypass technology, applied in the direction of filtration and separation, machine/engine, engine lubrication, etc., can solve the problems of no filtering effect, dirty bypass filter, small filtering area, etc., to prevent and quickly get dirty. Dirty, continuous cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

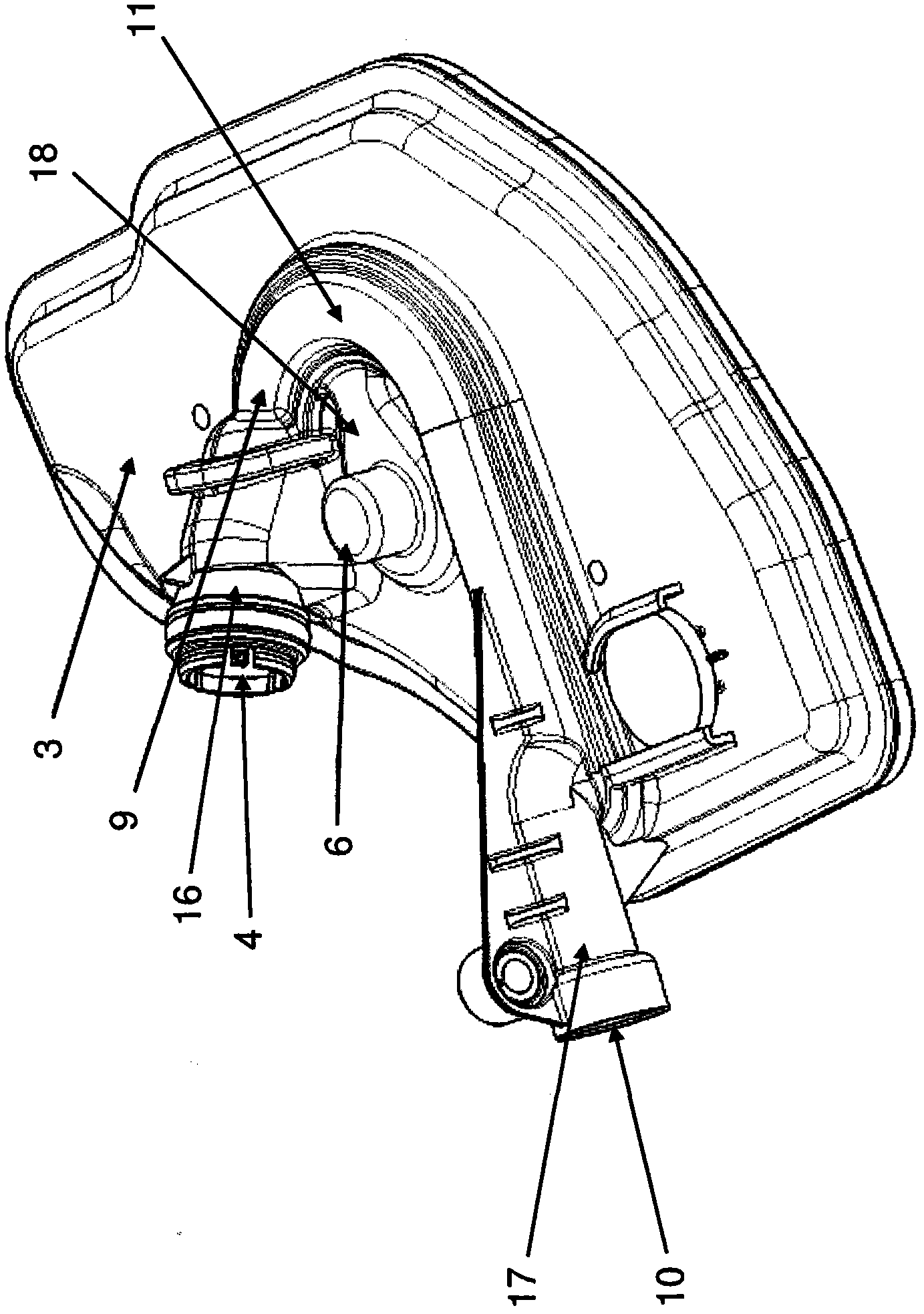

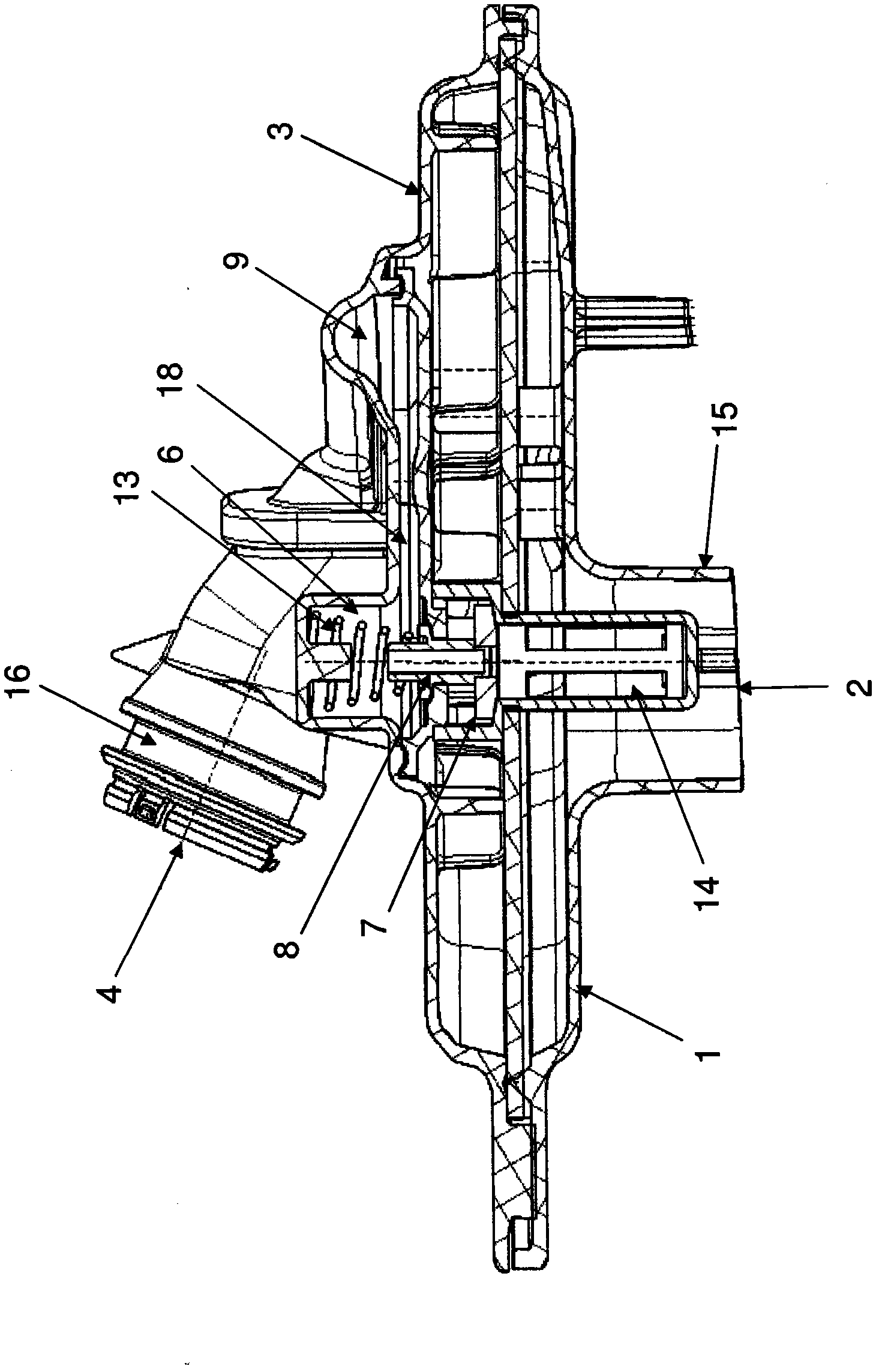

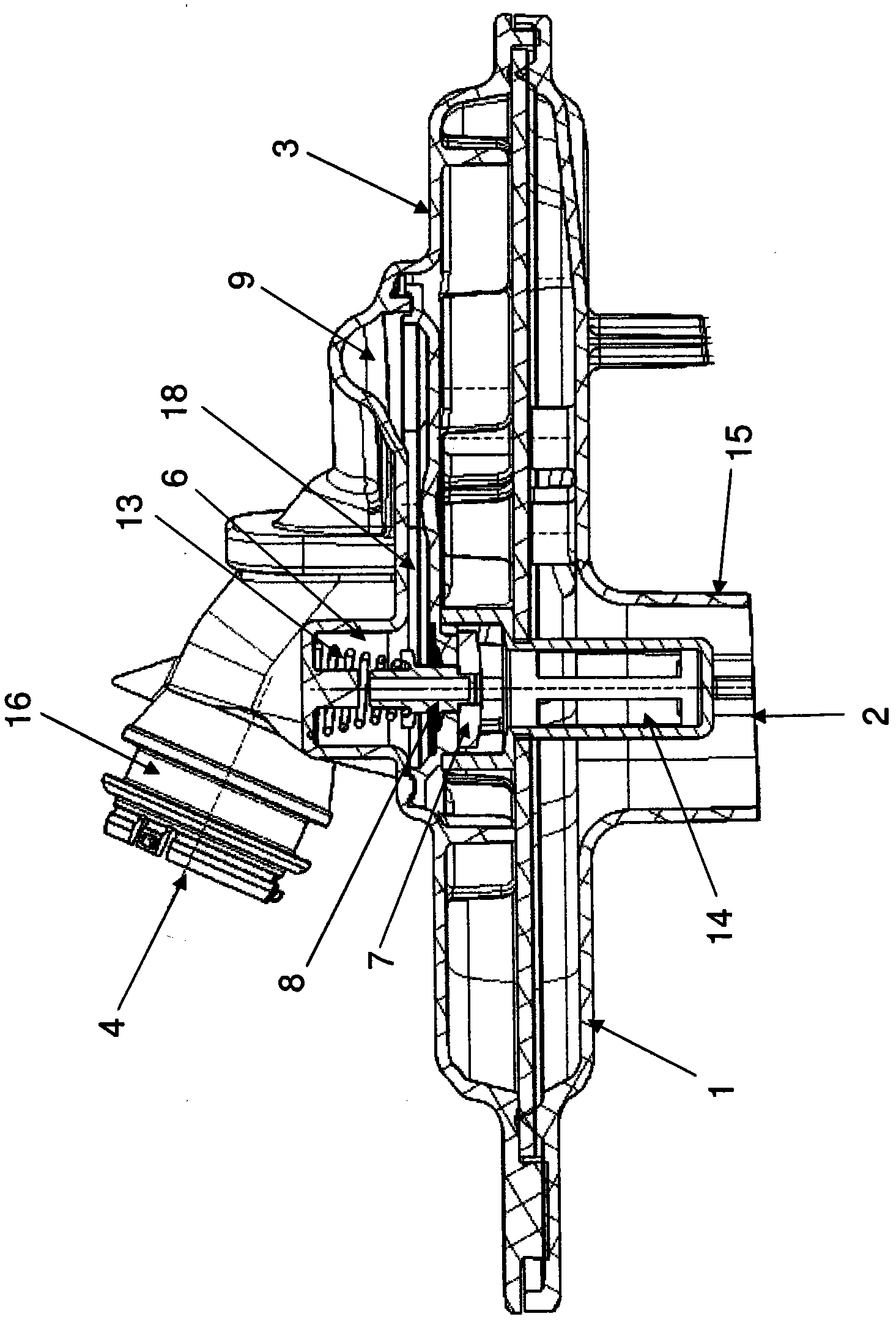

[0018] figure 1A possible embodiment of the oil suction filter according to the invention is shown in a perspective view looking at the upper side of the oil suction filter. This view shows the upper housing part 3 and part of the channel 9 integrated into the upper housing part 3 . In the example shown, channel 9 is a pressure channel for suction pressure boosting. When the channel 9 is configured as a closed channel to a certain extent, and only a part of the oil pumped through the oil outlet 4 by the pump not shown flows back to the channel 9, then also given according to the invention. figure 2 The control of the bypass valve 7 shown in , or more specifically its control piston 8 , wherein the oil pressure is related to the corresponding operating state of the oil suction filter. According to the example shown, the upper part of the channel 9 for the boosting of the suction pressure is formed here by a groove-like bead 11 on the upper side of the upper housing part 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com