Method for cleaning a combustion chamber of an internal combustion engine and internal combustion engine

A technology for internal combustion engines and combustion chambers, applied in combustion engines, internal combustion piston engines, combustion air/combustion-air treatment, etc., can solve problems such as complex injection devices, and achieve continuous cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

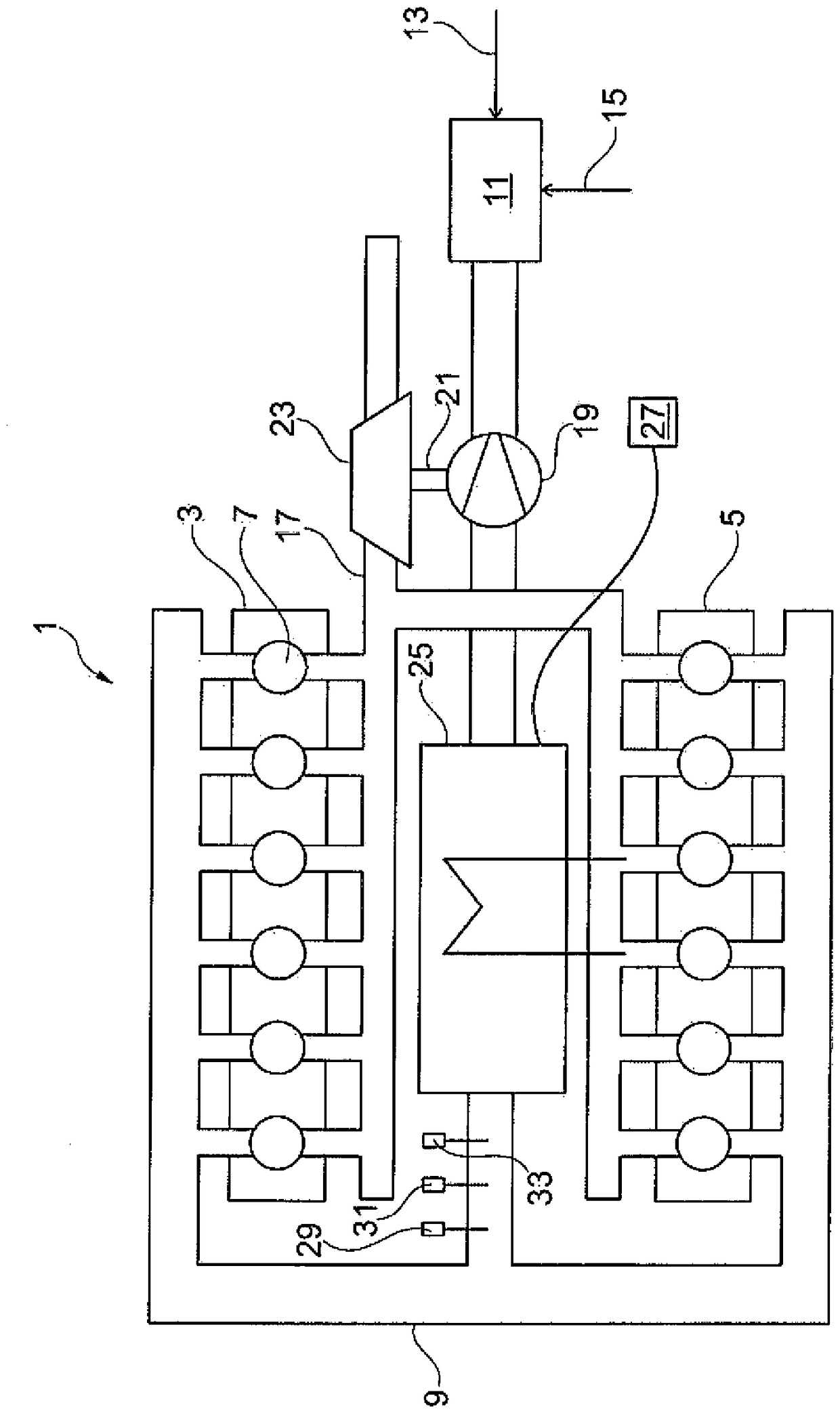

[0025] The drawing shows a schematic illustration of an exemplary embodiment of an internal combustion engine 1 . The internal combustion engine is here configured as a twelve-cylinder V-engine with a first cylinder bank 3 and a second cylinder bank 5, wherein each of the cylinder banks 3, 5 comprises six combustion chambers, where for better Only one of them is marked with reference number 7 for reasons of clarity. The gaseous substance is fed to the combustion chamber 7 via the feed line 9 . In the exemplary embodiment shown, this substance is formed as a mixture which is prepared in a gas mixer 11 from combustion air 13 and fuel 15 .

[0026] Combustion reactions are known to take place in the combustion chamber 7 , wherein residues, in particular exhaust gases, are produced, which are discharged via the discharge line 17 .

[0027] Downstream of the gas mixer 11 , the gas mixture is compressed in a compressor 19 , which is here driven via a shaft 21 by a turbine 23 , whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com