A continuous cleaning device for lithium battery electrode sheets

A cleaning device and electrode piece technology, which is applied to the cleaning method using tools, cleaning methods and utensils, and dust removal, etc., can solve the poor cleaning effect of the electrode piece cleaning device, dust is easy to adhere to the conveyor belt, secondary pollution of the electrode piece, etc. problems, to avoid damage to the electrode sheet, simple structure, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

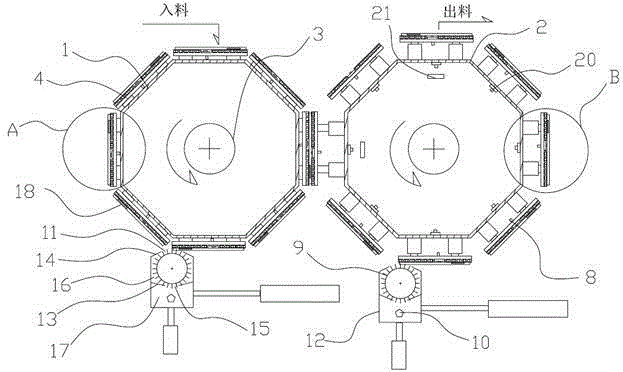

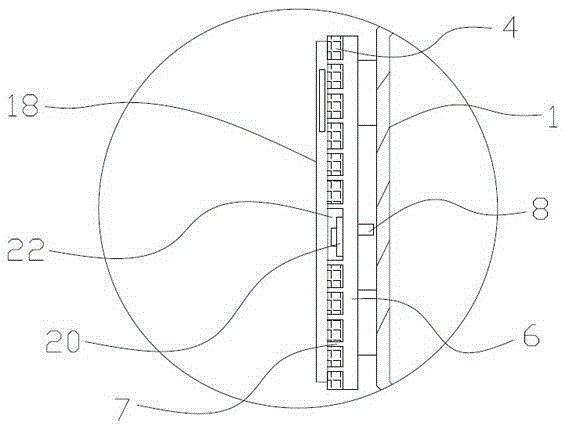

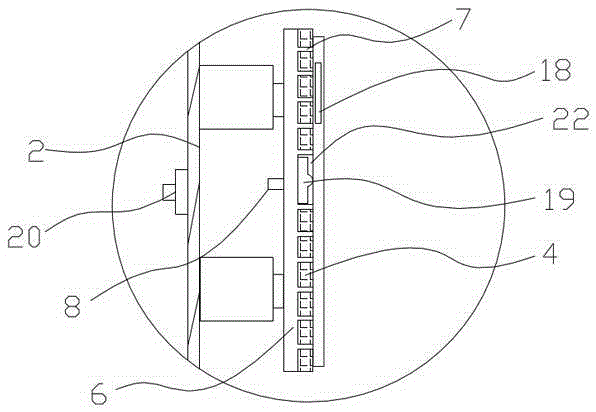

[0028] Such as figure 1 In the shown embodiment, a kind of continuous cleaning device of lithium battery electrode sheet comprises left wheel 1, right wheel 2, rolling brush 9, first push cylinder and dust collection box, left wheel 1 and right wheel The wheel 2 is axisymmetrically arranged and the cross-section is a regular octagon. The center of the left runner 1 and the right runner 2 are fixed with a rotating shaft 3 driven by a stepping motor. It is a vacuum adsorption plate 4 with a strip-shaped plate structure, and there is a gap between the relative vacuum adsorption plate 4 on the left runner 1 and the right runner 2, wherein the outer wall of the right runner 2 and the vacuum adsorption plate 4 are fixed with Two first push cylinders, the first push cylinders are respectively located on both sides below the vacuum adsorption plate 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com