Method for reducing discharge of fine particulates and metals during combustion process

A technology of fine particles and combustion process, used in fuels, fuel additives, petroleum industry, etc., can solve the problems of reduced concentration, low capture efficiency and little change, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in more detail below by means of the following examples, and the following examples are only illustrative, and the present invention is not limited by these examples.

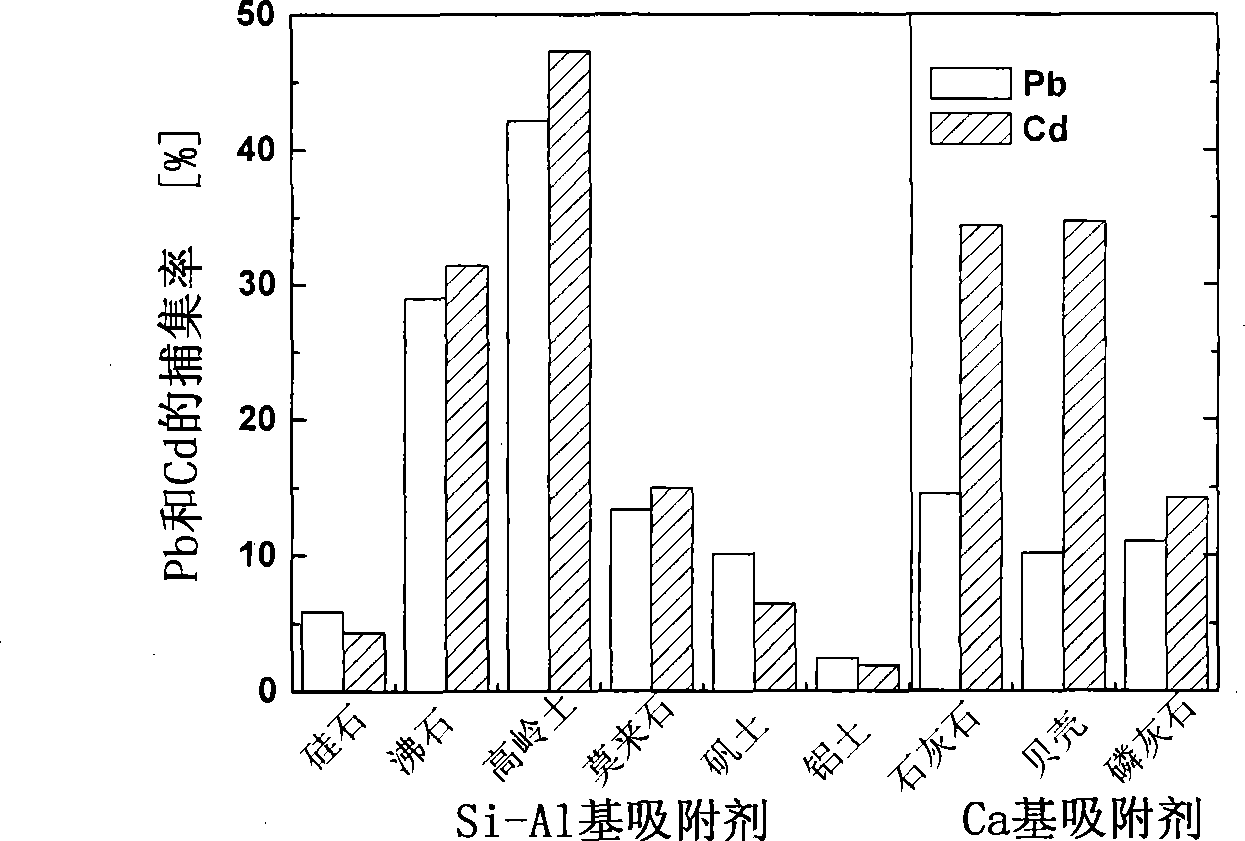

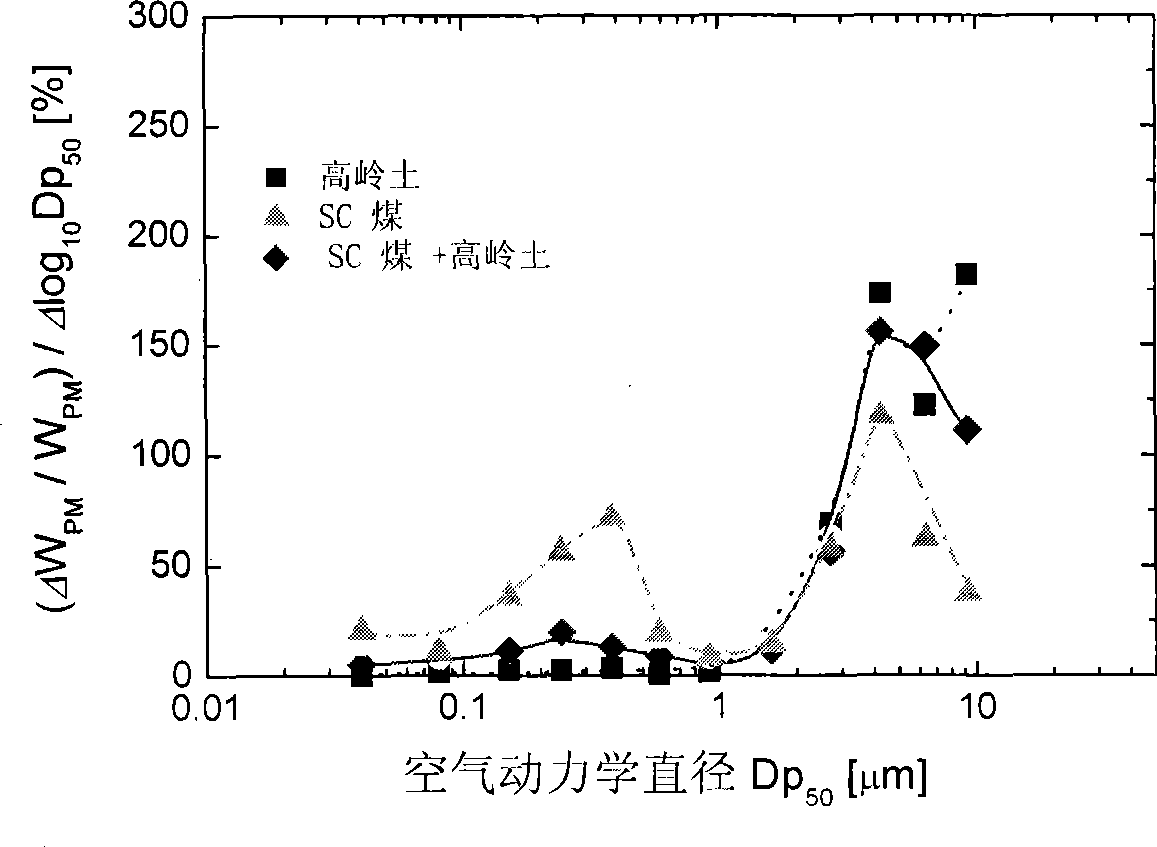

[0012] The method of the present invention is to inject 1g / Nm of flue gas into the high-temperature tail of coal-fired boilers and garbage incinerators. 3 —20g / Nm 3 The adsorbent, through chemical reaction and physical adsorption, the gaseous Na, K, Pb, Cd, etc. in the flue gas and PM 2.5 Converted into large particles that are easily removed by dust collectors.

[0013] At high temperature, it can be converted into solid particles with an aerodynamic particle size > 2.5 μm, which can be easily removed by the dust removal device, and at the same time greatly reduce Na, K, Pb, Cd, etc. and PM 2.5 Emissions to ambient air. Gaseous and aerosol toxic and harmful substances are converted into large particles of water-insoluble solids, which is beneficial to capture, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com