High-efficient zinc-rich anti-corrosive paint and preparation method thereof

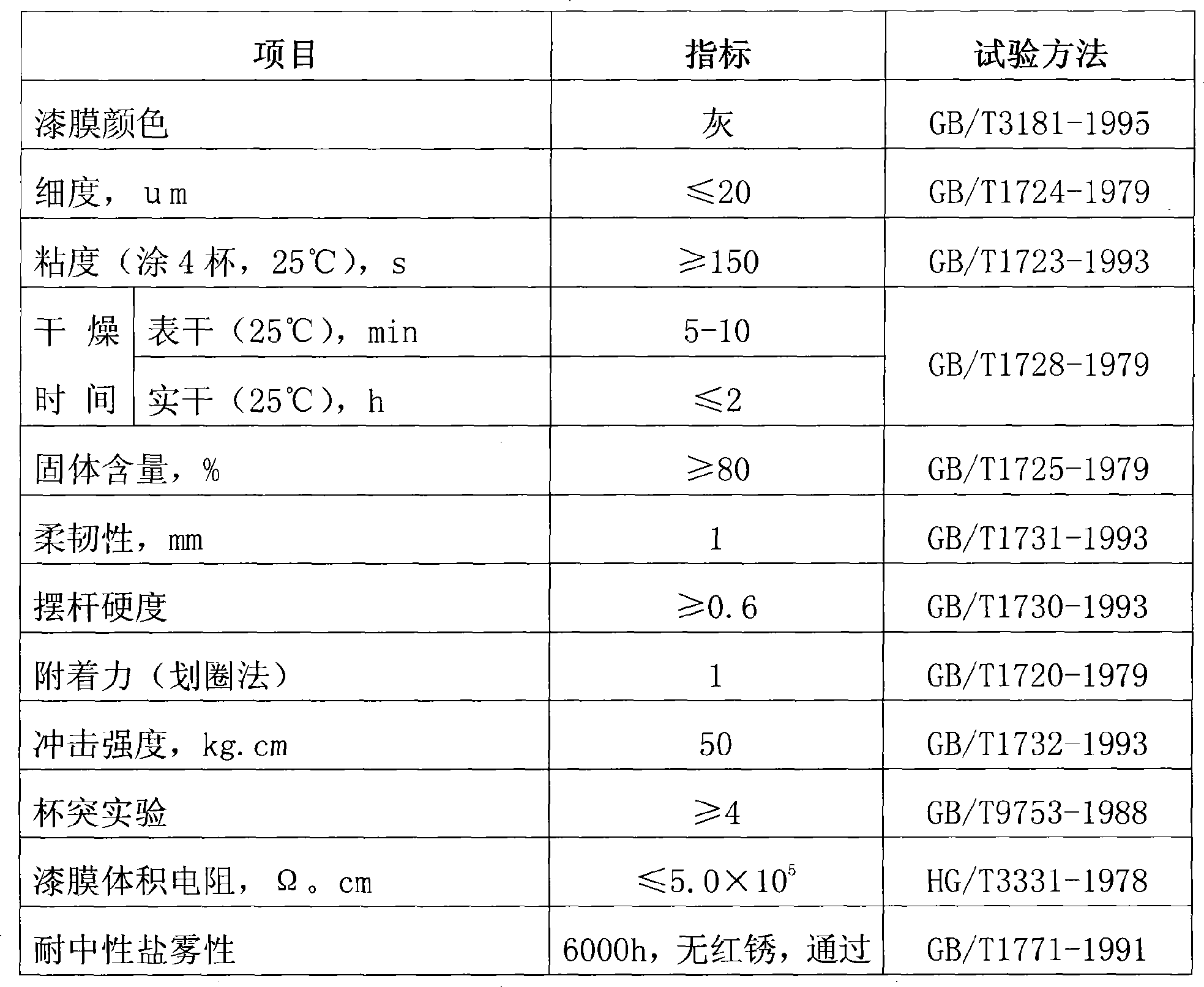

An anti-corrosion coating and zinc-rich technology, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve the problems of high porosity and poor shielding performance, and achieve the effects of low pollution, good antistatic performance, and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put in 11.0Kg ethyl acetate, ethanol, methyl ethyl ketone mixed solvent, add 0.4Kg simethicone, monoalkoxy pyrophosphate, oxidized polyethylene wax mixed additives and stir evenly, put in active zinc with an average particle size of 2-3um The powder is 86.0Kg, stirred at a high speed of 1000-1200rpm under normal temperature and pressure to obtain a zinc powder slurry with a fineness of ≤20um.

[0026] Put 2.6Kg EVOH, EVA, MP45, PVF resin into the above-mentioned zinc powder slurry, stir at 800-1000rpm at high speed until the resin is completely dissolved, and obtain the finished high-efficiency zinc-rich anti-corrosion coating.

Embodiment 2

[0028] Put in 15.2Kg ethyl acetate, ethanol, methyl ethyl ketone mixed solvent, add 0.4Kg simethicone, monoalkoxy pyrophosphate, oxidized polyethylene wax mixed additives and stir evenly, put in active zinc with an average particle size of 2-3um The powder is 82.0Kg, stirred at a high speed of 1000-1200rpm under normal temperature and pressure to obtain a zinc powder slurry with a fineness of ≤20um.

[0029] Put 2.4Kg of EVA VCAA and MP45 resin into the above-mentioned zinc powder slurry, and stir at a high speed of 800-1000rpm until the resin is completely dissolved to obtain a finished high-efficiency zinc-rich anti-corrosion coating.

Embodiment 3

[0031] Put in 19.0Kg of ethyl acetate, ethanol, methyl ethyl ketone mixed solvent, add 0.3Kg of simethicone, monoalkoxy pyrophosphate, oxidized polyethylene wax mixed additives and stir evenly, put in active zinc with an average particle size of 2-3um The powder is 78.0Kg, stirred at a high speed of 1000-1200rpm under normal temperature and pressure to obtain a zinc powder slurry with a fineness of ≤20um.

[0032] Put 2.2Kg of VAOH, VCAA, MP45 resin into the above-mentioned zinc powder slurry, stir at 800-1000rpm at high speed until the resin is completely dissolved, and obtain the finished high-efficiency zinc-rich anti-corrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com