Non-rolling construction method for vertical cylinder storage tank and fixture thereof

A construction method and cylindrical technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of high cost, complicated installation and construction process, and many construction personnel and auxiliary equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

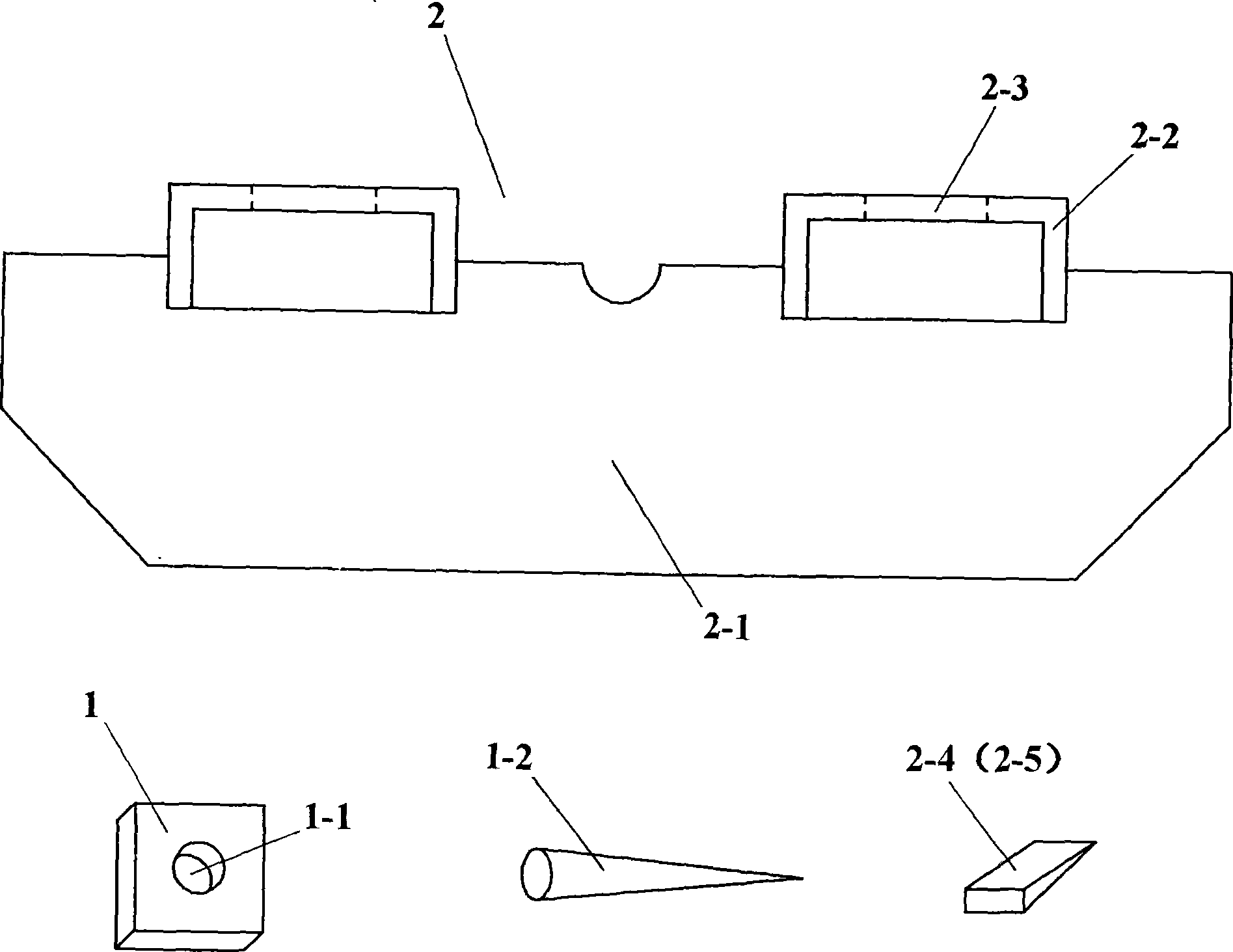

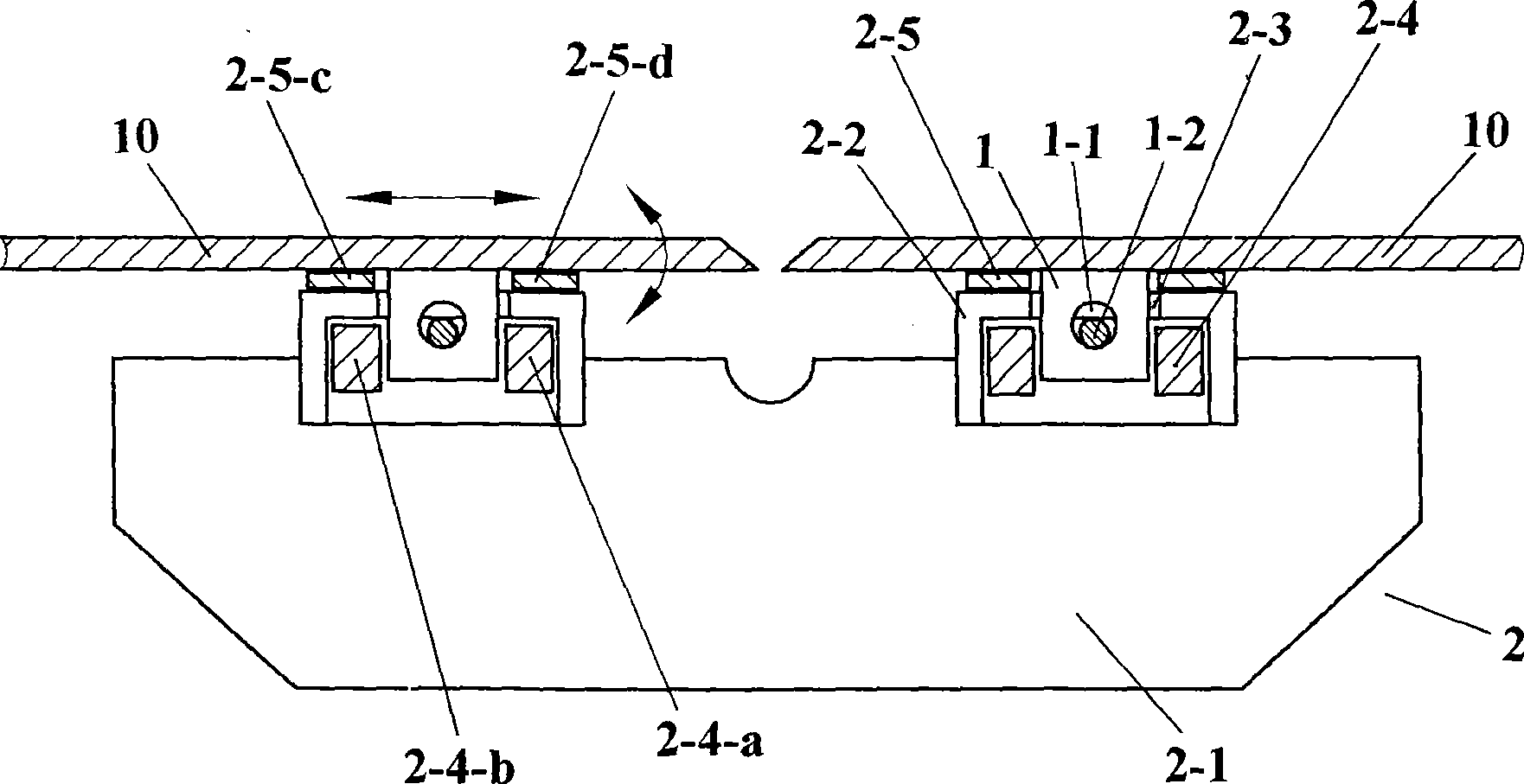

[0054] Example 1: Fixture for vertical weld adjustment

[0055] In the construction method of the present invention, most of the entire wall board can be adjusted to the required radian by the elasticity of the steel plate, but the rigidity at the junction of the two edges of the wall board is high, so it is difficult to automatically adjust the required radian . For this reason, the inventor of the present invention has invented a vertical welding seam adjustment jig with simple structure, convenient adjustment, easy mastery and high adjustment accuracy after years of repeated research and testing, and realized the adjustment of vertical cylindrical storage tanks. The non-coiling construction method is the special key equipment for realizing the technology of the present invention.

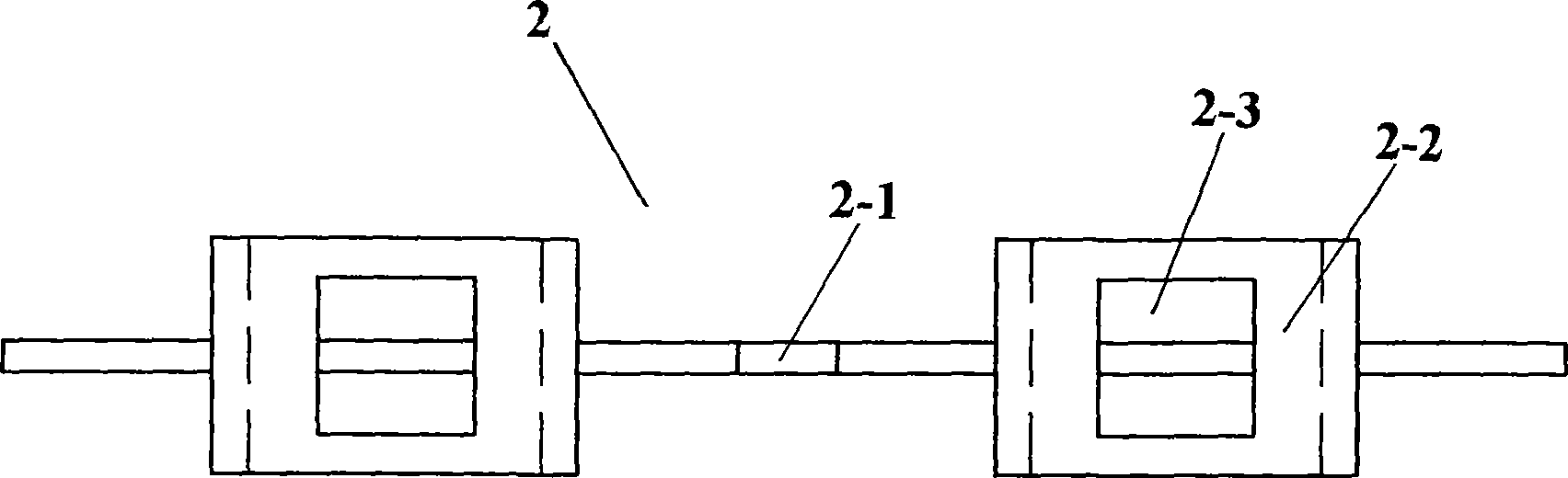

[0056] 1. The structure of vertical welding seam adjustment jig

[0057] refer to figure 1 , 2 , this vertical seam adjustment jig is made up of a vertical seam positioning plate 1 and a vert...

Embodiment 2

[0064] Construction of a vertical cylindrical atmospheric pressure storage tank with an inner diameter of 15 meters, a height of 10.67 meters, and a volume of 2,000 cubic meters without coiling

[0065] 1. Preparations related to the present invention before construction:

[0066] (1) Prepare the vertical weld adjustment jig according to Example 1

[0067] in:

[0068] Each vertical welding seam positioning plate: square, 30 mm thick, 50 mm long and 50 mm wide, with a circular fixing hole with a diameter of 25 mm in the center, and a conical fixing pin with a diameter of 30 mm and a length of 250 mm.

[0069]Each vertical weld adjustment plate: rib plate thickness 14 mm, length 520 mm, width 150 mm, center distance of 2 Π-shaped positioning plates 300 mm, Π-shaped positioning plate thickness 12 mm, horizontal plate length 125 mm, width 140 mm , the two side plates are 125 mm long and 50 mm wide, the positioning plate fixing hole is 80 mm long and 60 mm wide, and there are re...

Embodiment 3

[0105] Construction of a vertical cylindrical atmospheric water tank with an inner diameter of 27 meters, a height of 14.5 meters, and a volume of 8,000 cubic meters without coils

[0106] 1. Preparation before construction:

[0107] (1) Adjustment jig:

[0108] Each vertical welding seam positioning plate, conical fixed pin; vertical welding seam adjustment plate, seam width adjustment positioning wedge, radian adjustment positioning wedge; limit plate, bottom ring wall plate positioning wedge; wall plate positioning frame, wall plate positioning plate , wall plate positioning wedge etc. are basically the same as embodiment 2.

[0109] (2) Wall panels of each belt:

[0110] The water tank is composed of 6 wall panels, and the size (unit: mm) and quantity of the wall panels of each belt are shown in Table 2.

[0111] 2. Construction steps:

[0112] (1) On the two inner edges of the 9 bottom ring panels to be installed, 150mm from the two edges, 420mm from the upper edge, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com