Method and device for regenerating washing agent

A detergent and gas scrubbing technology, applied in separation methods, chemical instruments and methods, liquid scrubbing gas purification, etc., can solve problems such as unfavorable operating costs of gas purification, reduce equipment downtime, prevent moving, and improve economical efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

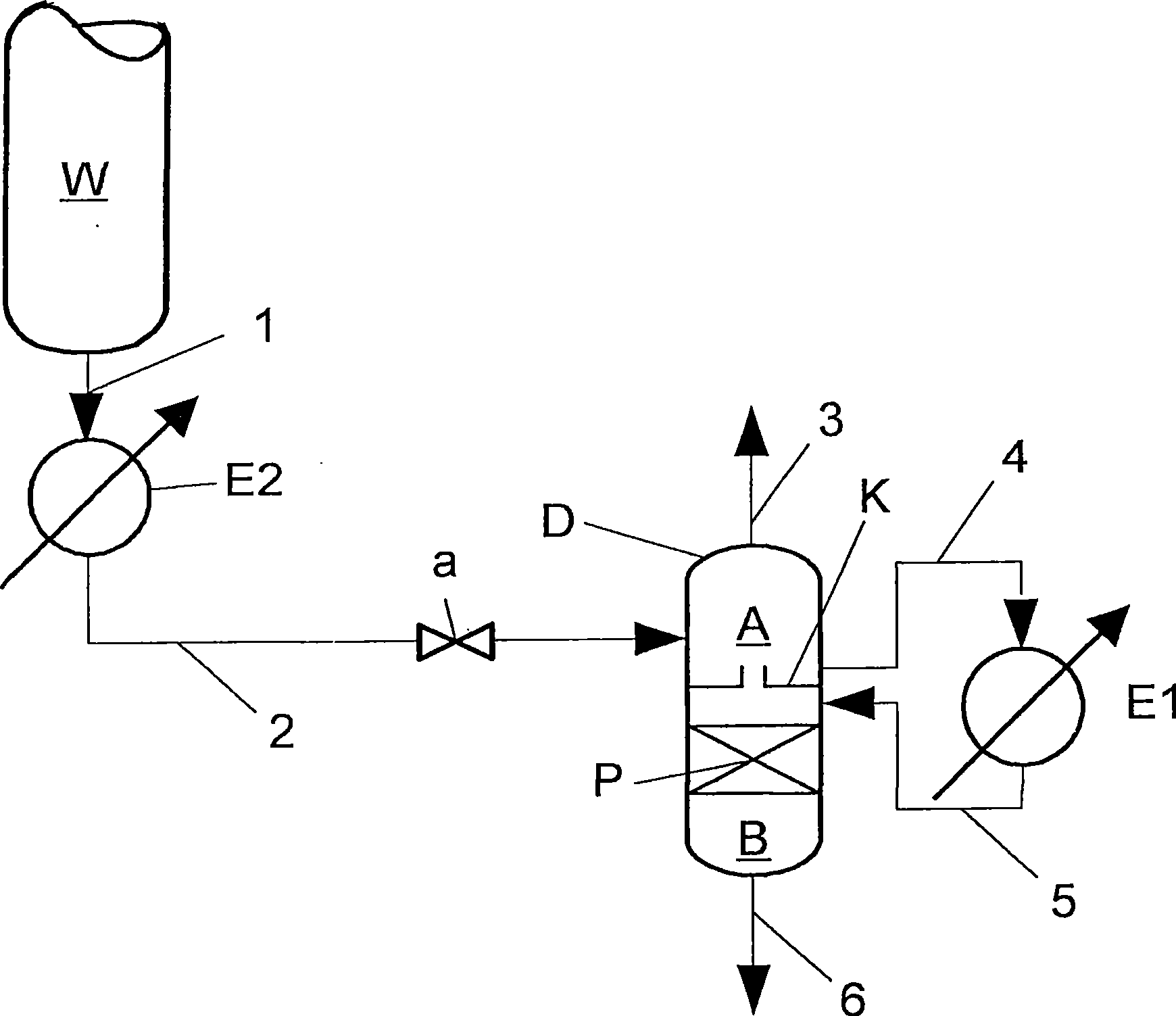

[0024] This example relates to synthesis gas scrubbing in which low temperature methanol is used as a physically acting scrubber. The syngas to be cleaned originates from a gasification unit (not shown) in which a charge (e.g. carbon and / or heavy oil) containing carbon, sulfur and heavy metals (e.g. nickel and / or iron) is transform. Metal carbonyls arising from heavy metals during the gasification of the charge travel with the raw synthesis gas to the synthesis gas scrubber and are scrubbed there.

[0025]Synthetic raw gas scrubbing is carried out in the scrubber W. From the liquid phase pool of the scrubber W, the methanol scrubber loaded with metal carbonyl compounds and sulfur components and carbon monoxide is drawn through the pipeline 1 at a pressure of about 60 bar, and the heat is introduced. in exchanger E2 and heated there to about 70°C. The heated methanol scrubber laden with metal carbonyls is conveyed through line 2 to throttling mechanism a, through which it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com