Carrying device with cylinder vertical fixing function

A technology of fixed function and handling device, applied in transportation and packaging, multi-axis trolleys, trolleys, etc., can solve the problems of difficulty in vertical placement, inconvenient transportation, time-consuming and labor-intensive, and achieve rich functions, simple and compact structure, convenient and labor-saving use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

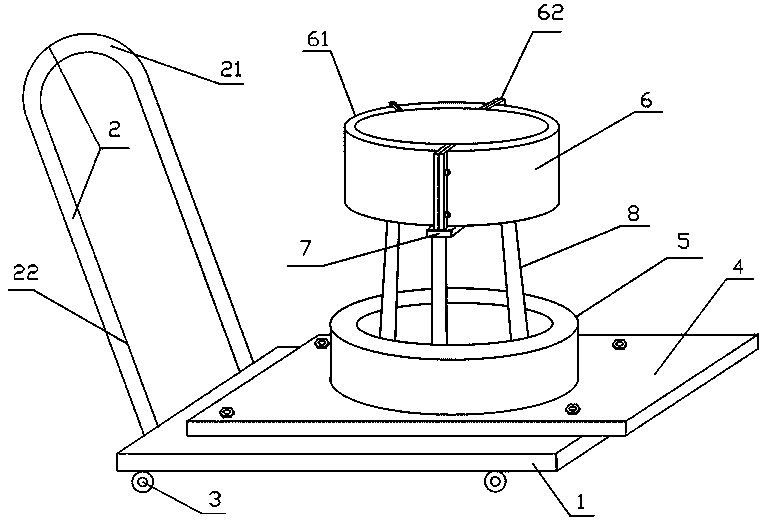

[0026] Such as figure 1 As shown, the gas cylinder handling device with vertical fixing function includes a base plate 1, a cart handle 2, a roller 3, a fixed plate 4, a fixed cylinder seat 5, a ring fixed frame 6, a support plate 7, and a support leg 8. The lower end of the trolley handle 2 is fixed on the side of the base plate 1, and the roller 3 is installed below the base plate 1; the fixed plate 4, the fixed cylinder seat 5, the ring fixed frame 6, the support plate 7, and the support legs 8 form a gas cylinder fixing mechanism :

[0027] The fixed plate 4 is located above the base plate 1, and is detachably connected to the base plate 1 through a detachable connector, and part of the fixed plate 4 protrudes out of the base plate 1. The detachable connector is such as but not limited to bolts, screws, studs, When it is necessary to disassemble the gas cylinder fixing mechanism composed of the fixing plate 4 and the parts on it, remove the aforementioned detachable conne...

Embodiment 2

[0034] On the basis of Embodiment 1, the bottom plate 1 and the fixed plate 4 in the present embodiment are rectangular plates, and the fixed plate 4 has two sides extending out of the bottom plate 1, which is convenient for the bottom plate 1 and the gas cylinder fixing mechanism thereon to be formed. The parts are removed together from the bottom plate 1 of the cart. The aforementioned two sides can be the two sides located on both sides of the cart handle 2, or any one located on the side of the cart handle 2 and the side opposite to the cart handle 2; there are 8 rollers 3 in this embodiment , two under the four corners of the base plate 1 are respectively arranged, and the gas cylinder handling device walks more stably during the handling process.

Embodiment 3

[0036] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the cart handle 2 is further improved. The cart handle 2 includes two push rods 22 whose lower ends are connected to the side of the bottom plate 1 and connected to the tops of the two push rods 22. Push handle 21, 2 push rods 22 lower ends are connected on the same side of base plate 1 and 2 push rods 22 are parallel to each other, and the two ends of push handle 21 are respectively connected to a push rod 22 tops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com