Activated waste rubber powder and preparation thereof

A technology of waste rubber powder and activator, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems such as the limitation of modified rubber powder, and achieve the effect of improving impact resistance and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

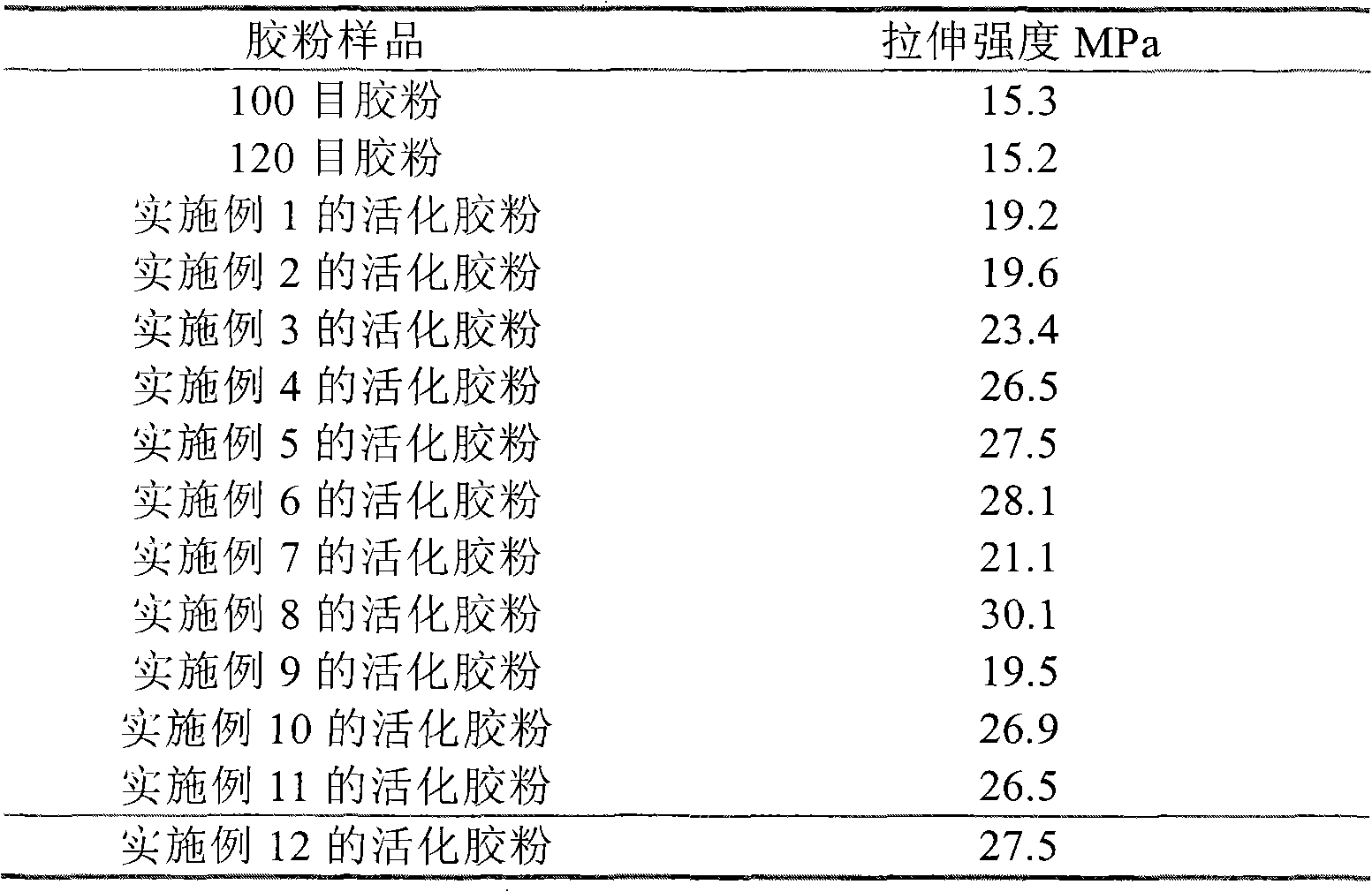

Examples

Embodiment 1

[0016] Weigh 100 grams of 100-mesh rubber powder, put it into a 500 ml four-necked flask with stirring, heating, condensation, and nitrogen devices, add 100 grams of styrene containing 0.03% benzoyl peroxide by mass, and soak the rubber powder for 4 hours After the styrene permeates into the rubber powder, start stirring, protect with nitrogen, heat up to 100°C, react for 2 hours, the product becomes viscous, heat up to 120°C and react for 1 hour, cool to obtain polystyrene-wrapped, interspersed And grafted activated rubber powder.

Embodiment 2

[0018] Weigh 100 grams of 120-mesh rubber powder, put it into a 500 ml four-necked flask with stirring, heating, condensation, and nitrogen devices, add 80 grams of styrene containing 0.03% benzoyl peroxide by mass, and soak the rubber powder for 4 hours After the styrene permeates into the rubber powder, start stirring, protect with nitrogen, heat up to 100°C, react for 2 hours, the product becomes viscous, heat up to 120°C and react for 1 hour, cool to obtain polystyrene-wrapped, interspersed And grafted activated rubber powder.

Embodiment 3

[0020] Weigh 200 grams of 100-mesh rubber powder, wrap it with a filter cloth and place it in a rapid extractor, use 500 ml of a 1:1 mixed solvent of benzene and isopropanol, extract at 100°C for 12 hours, and take out the filter cloth Dry the rubber powder in it. Take by weighing 100 grams of dried rubber powder and put it into a 500 milliliter four-necked flask with stirring, heating, condensation, and nitrogen devices, add 80 grams of styrene containing 0.01% benzoyl peroxide by weight and soak the rubber powder for 4 Hours, after the styrene has basically penetrated into the rubber powder, start stirring, protect with nitrogen, heat up to 80°C, react for 2 hours, the product becomes viscous, heat up to 100°C and react for 1 hour, cool to get polystyrene wrapped , Interpenetrated and grafted activated rubber powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com