Colloid curing device

A curing device and colloidal technology, which is applied to the device, installation, optics and other directions of coating liquid on the surface, can solve the problems of damage to the workpiece 22, the inability to ensure that the colloid is completely cured, and fall, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

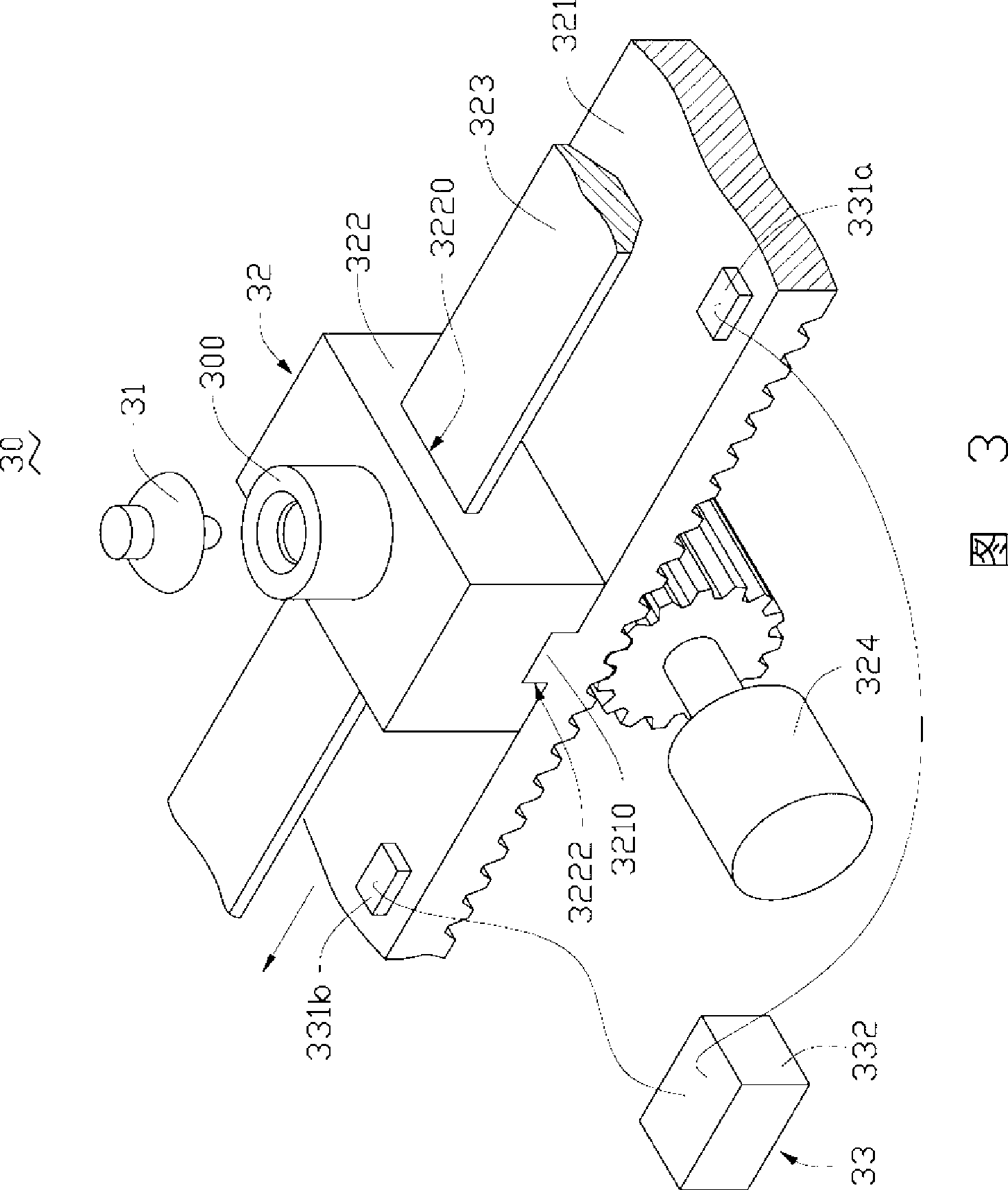

[0017] As shown in FIG. 3 , a glue curing device 30 provided by an embodiment of the present invention includes a curing lighting device 31 , a carrying device 32 and a sensing control unit 33 .

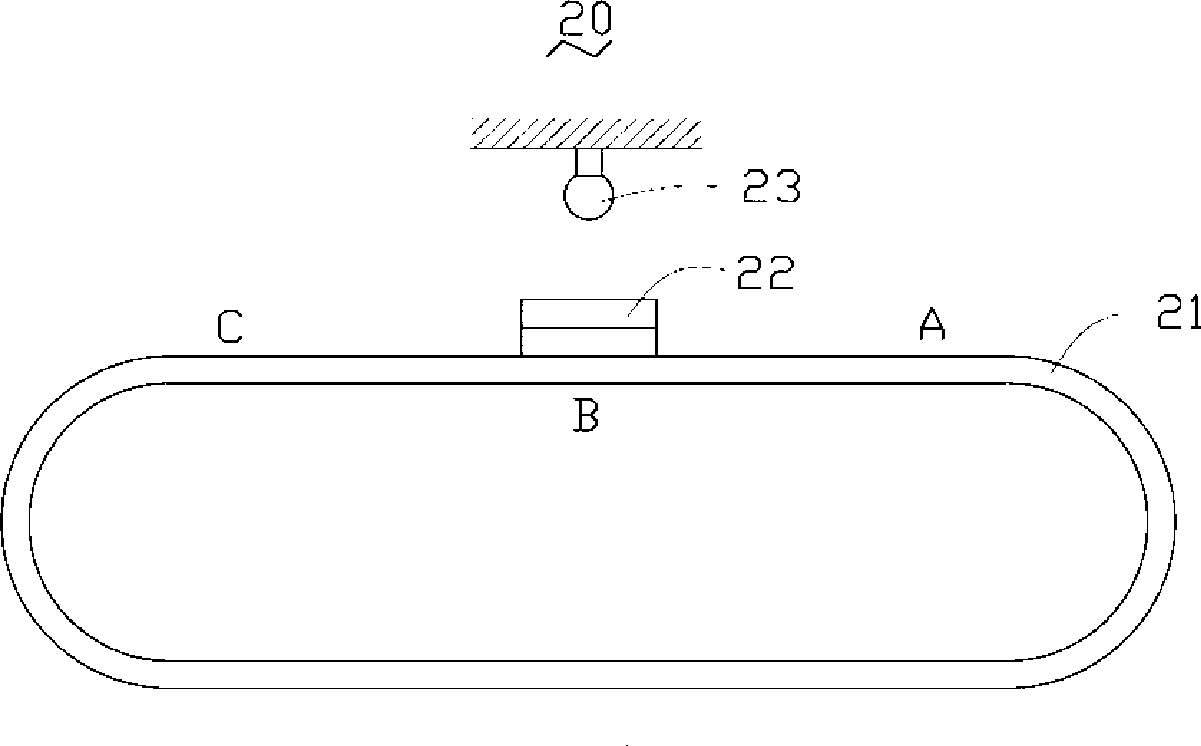

[0018] The curing lighting device 31 can be an ultraviolet light source for irradiating the workpiece 300 . In this embodiment, the workpiece 300 can specifically be a lens and a spacer ring (not shown) loaded in a lens barrel (not shown), and the contact surfaces of the lens and the spacer ring are coated with colloid.

[0019] The carrying device 32 is used to carry the workpiece 300 and transport the workpiece 300 . Specifically, the carrying device 32 includes a conveyor belt 321 and a carrying platform 322 for carrying the workpiece 300 . Wherein, the carrying platform 322 is fixed on the transmission belt 321 and driven by the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com