Self-wind cooled rotor double stator low torque ripple magneto resistance genus motor

A torque pulsation, double-stator technology, applied in the direction of cooling/ventilation devices, magnetic circuit rotating parts, electric components, etc., can solve the problems affecting the life of the winding, the temperature rise of the stator and rotor, and the inoperability of the motor, so as to improve the saturation The effects of magnetic density selection, reduced heat dissipation area, and reduced volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

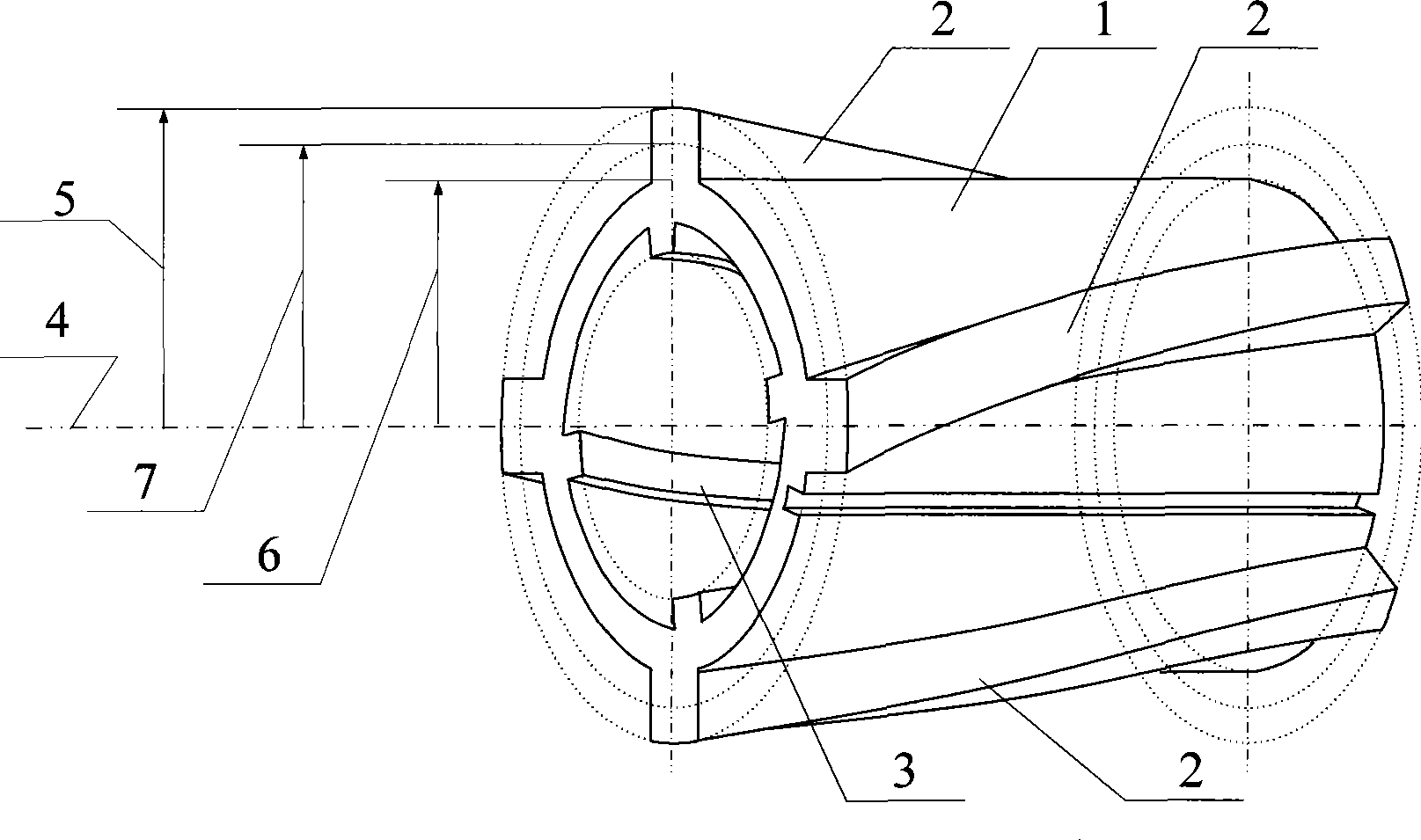

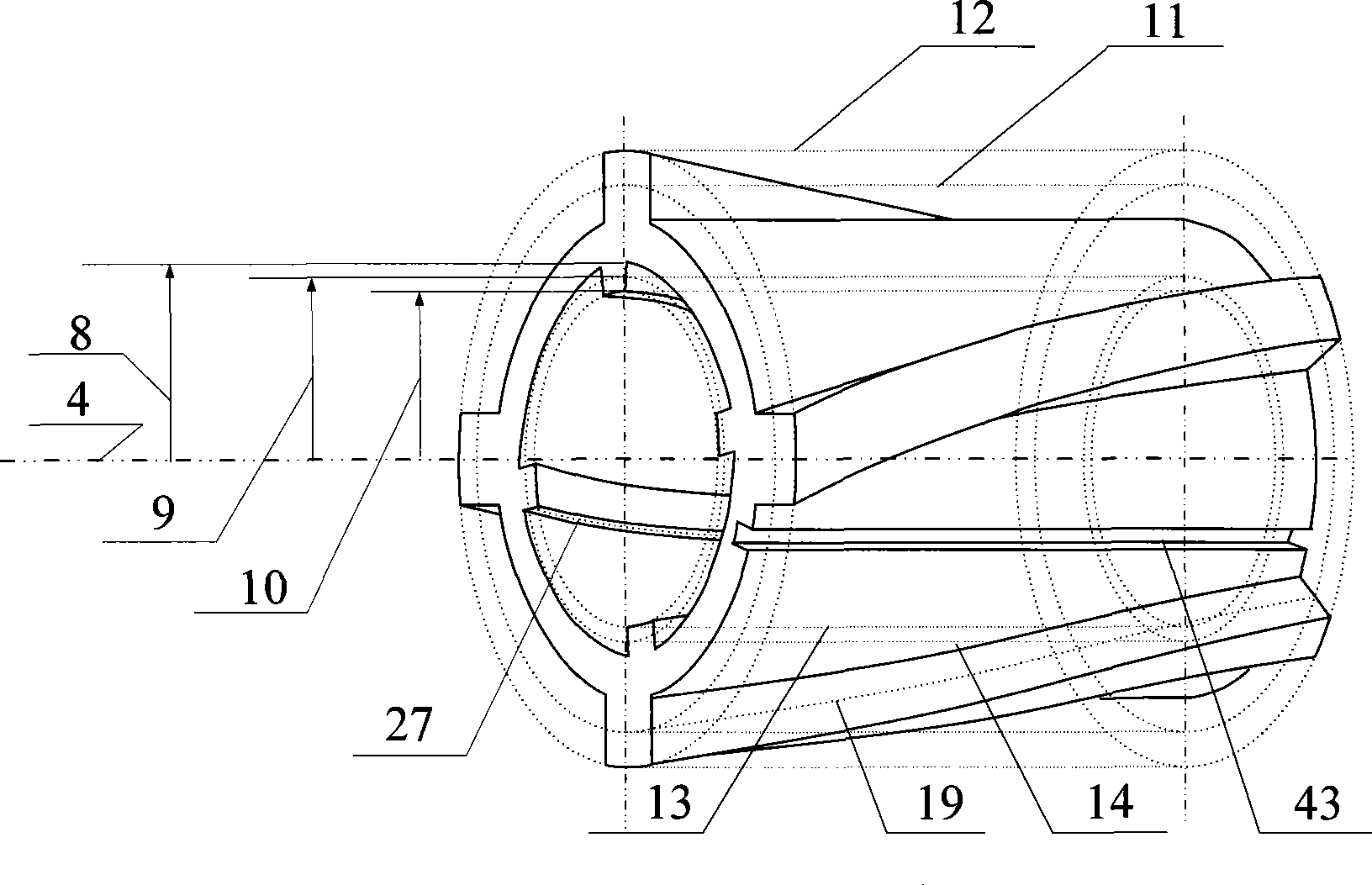

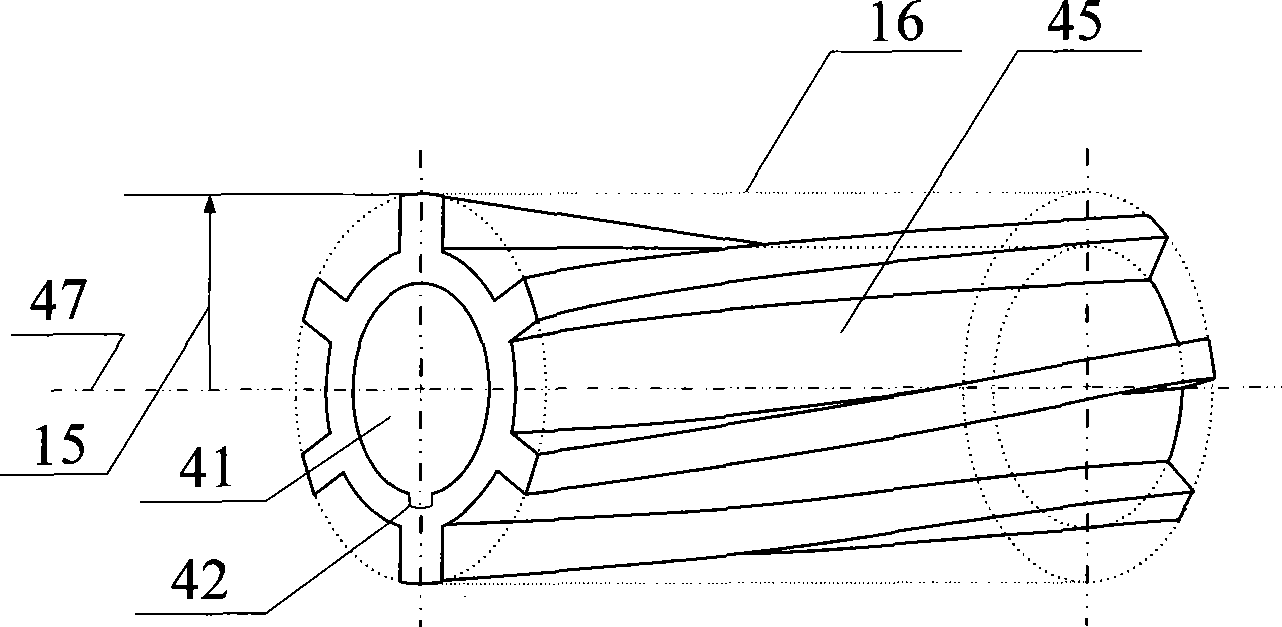

[0030] Taking the double salient pole motor as an example, since the rotor of the double salient pole motor has only salient pole teeth and tooth slots, and no windings, the present invention proposes the use of salient pole Due to the structural characteristics of teeth and cogging, the salient pole teeth of the double salient pole motor rotor are designed as the blade structure shape of the axial flow fan, so that the air around one end of the rotor (intake end) can be sucked into the rotor teeth of the motor when the rotor rotates. Slot, and then go out from the other end of the rotor (air outlet), directly take away the heat generated by the motor rotor to cool the motor. In order to achieve this purpose, the shape of the salient pole teeth of the rotor can be designed according to the working principle of the blades of the axial flow fan.

[0031] figure 1 and figure 2 The rotor structure diagram of the 6 / 4 / 4 / 6-pole self-wind-cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com