Novel tooth form of screw rod rotor of double-screw compressor

A compressor and twin-screw technology, used in mechanical equipment, machines/engines, rotary piston pumps, etc., can solve the problems of airflow disturbance, easy rotor wear, and easy rotor impact, so as to reduce aerodynamic loss, reduce Lateral leakage, the effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] specific implementation plan

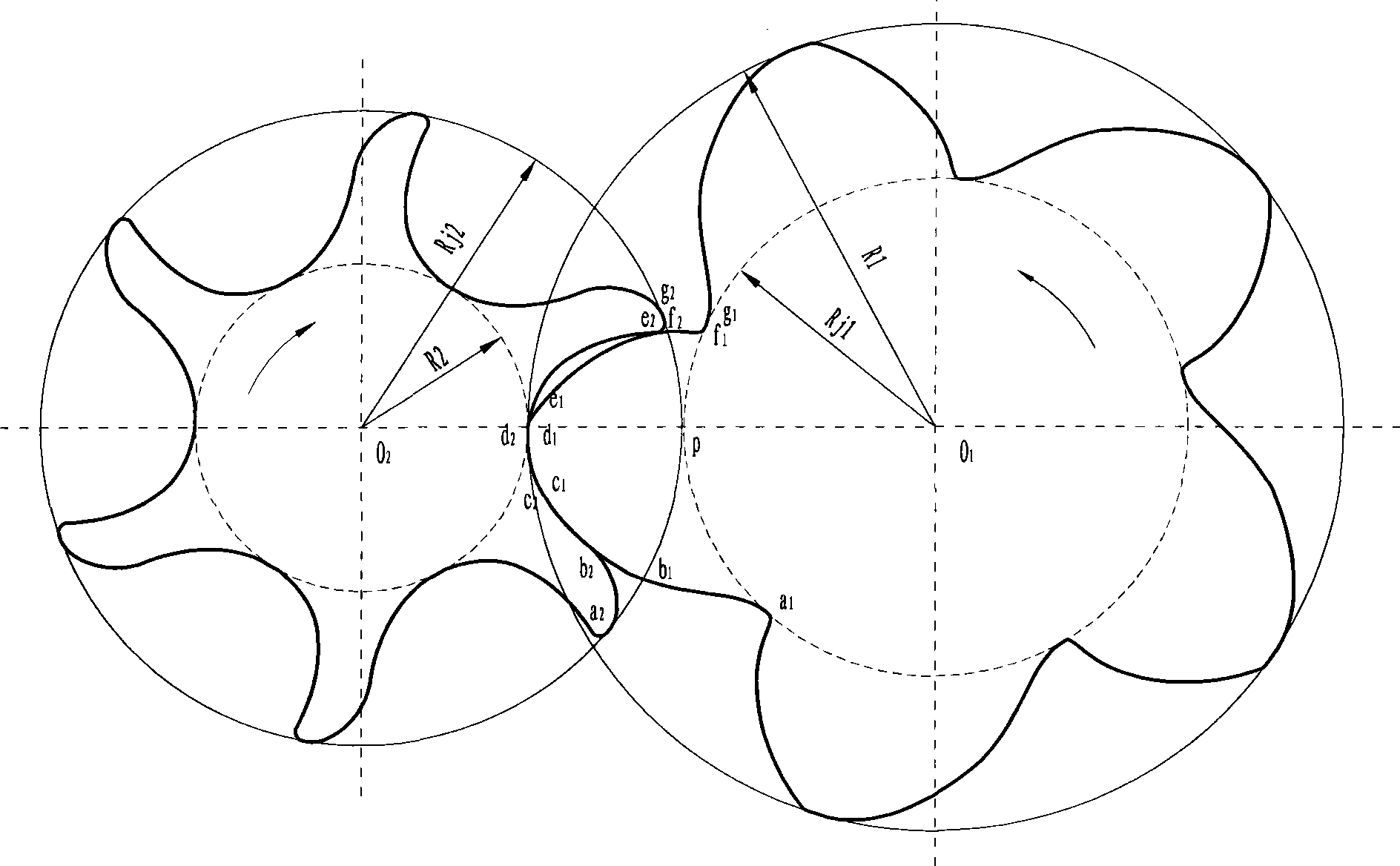

[0031] see figure 1 . The new tooth shape of the screw rotor of the twin-screw compressor of the present invention includes the tooth shape 1 of the male rotor and the tooth shape 2 of the female rotor. The tooth profiles of the male and female rotors are asymmetrical. The number of teeth on the female rotor is one or two more than the number of teeth on the male rotor. In this embodiment, the teeth on the male rotor and the teeth on the female rotor adopt a five-to-six asymmetric tooth shape, wherein the male rotor has five teeth, and the female rotor has six teeth. Each tooth of the male rotor 1 and the female rotor 2 is formed by smooth connection of six sections of curves. These curves include ellipses, arcs and their envelopes without any sharp points or sharp edges. Usually the female rotor is driven by the male rotor, and the steering is as figure 1 shown. center line O 1 o 2 is the dividing line, the lower half is the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com