III-nitride transistor epitaxial structure and transistor device

A technology of epitaxial structures and nitrides, which is applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of complicated process steps, low threshold voltage of enhanced HEMT devices, unsuitable for production and application, and achieve high electronic efficiency. Mobility, suppression of lateral leakage, and effects of improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

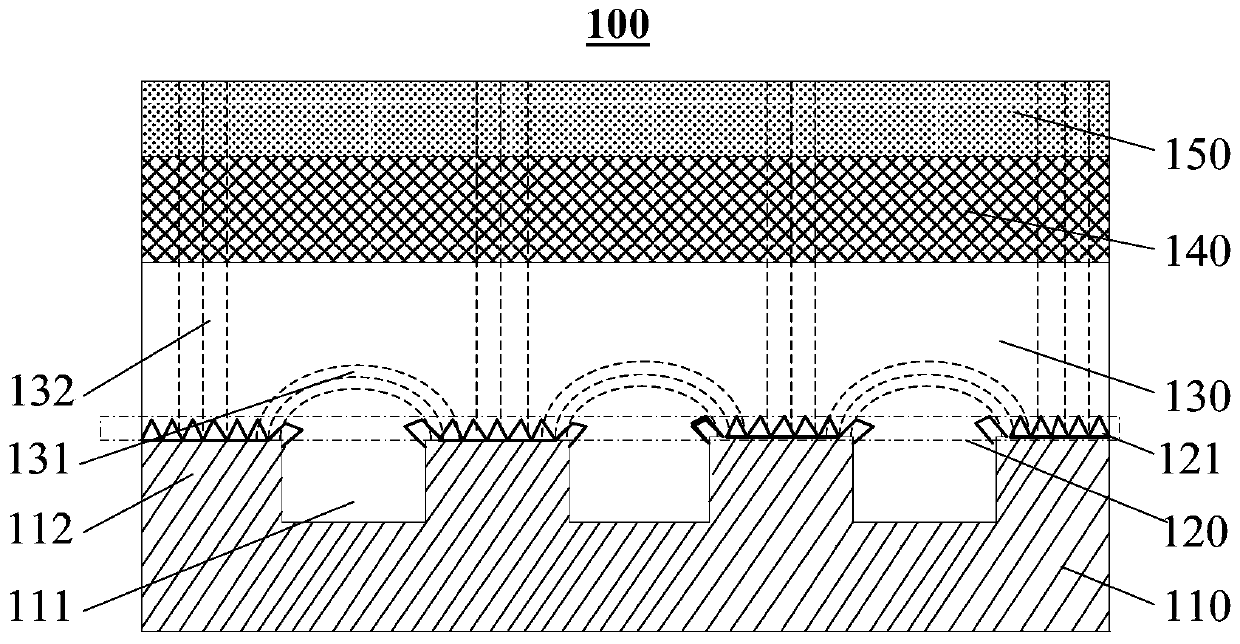

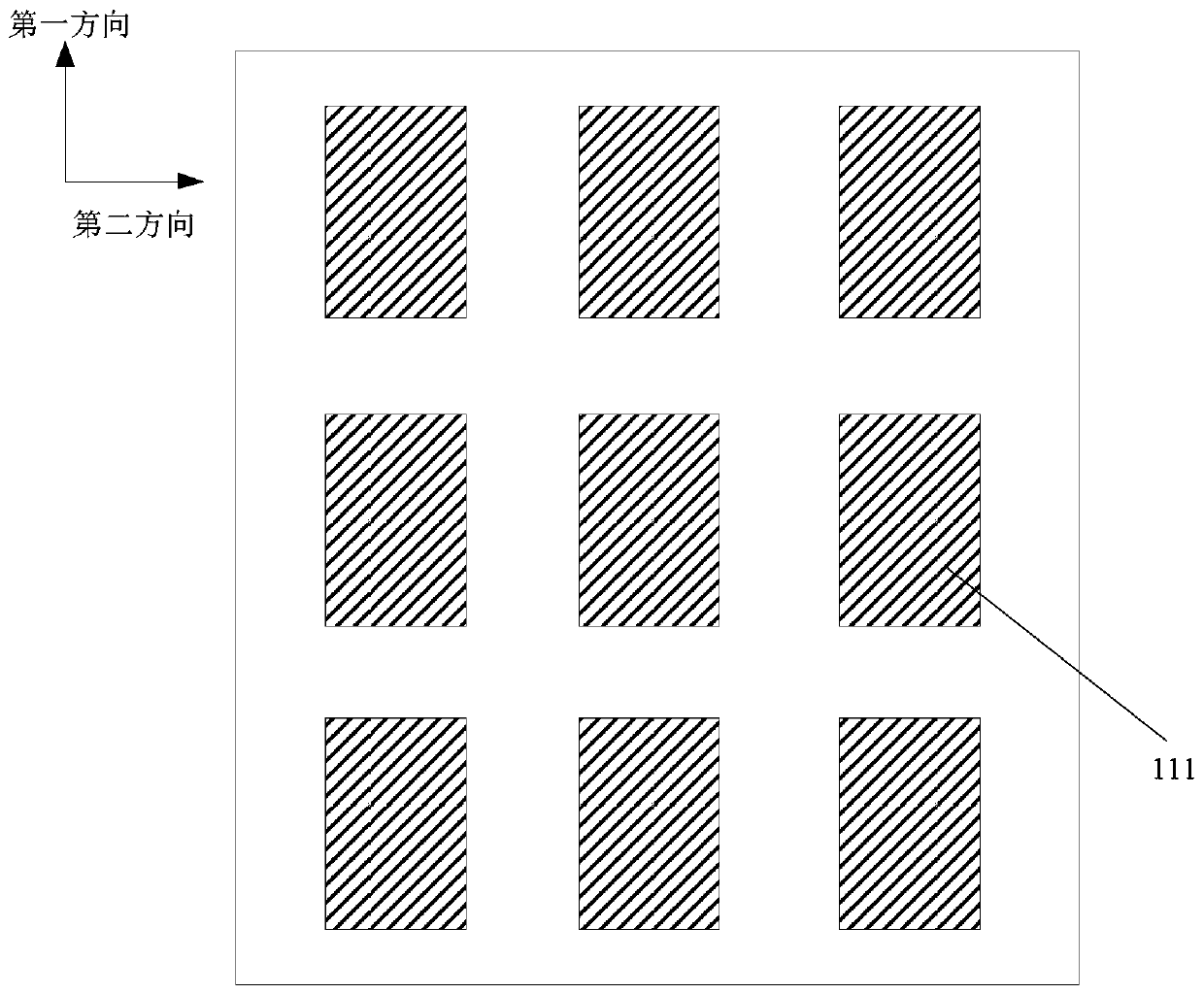

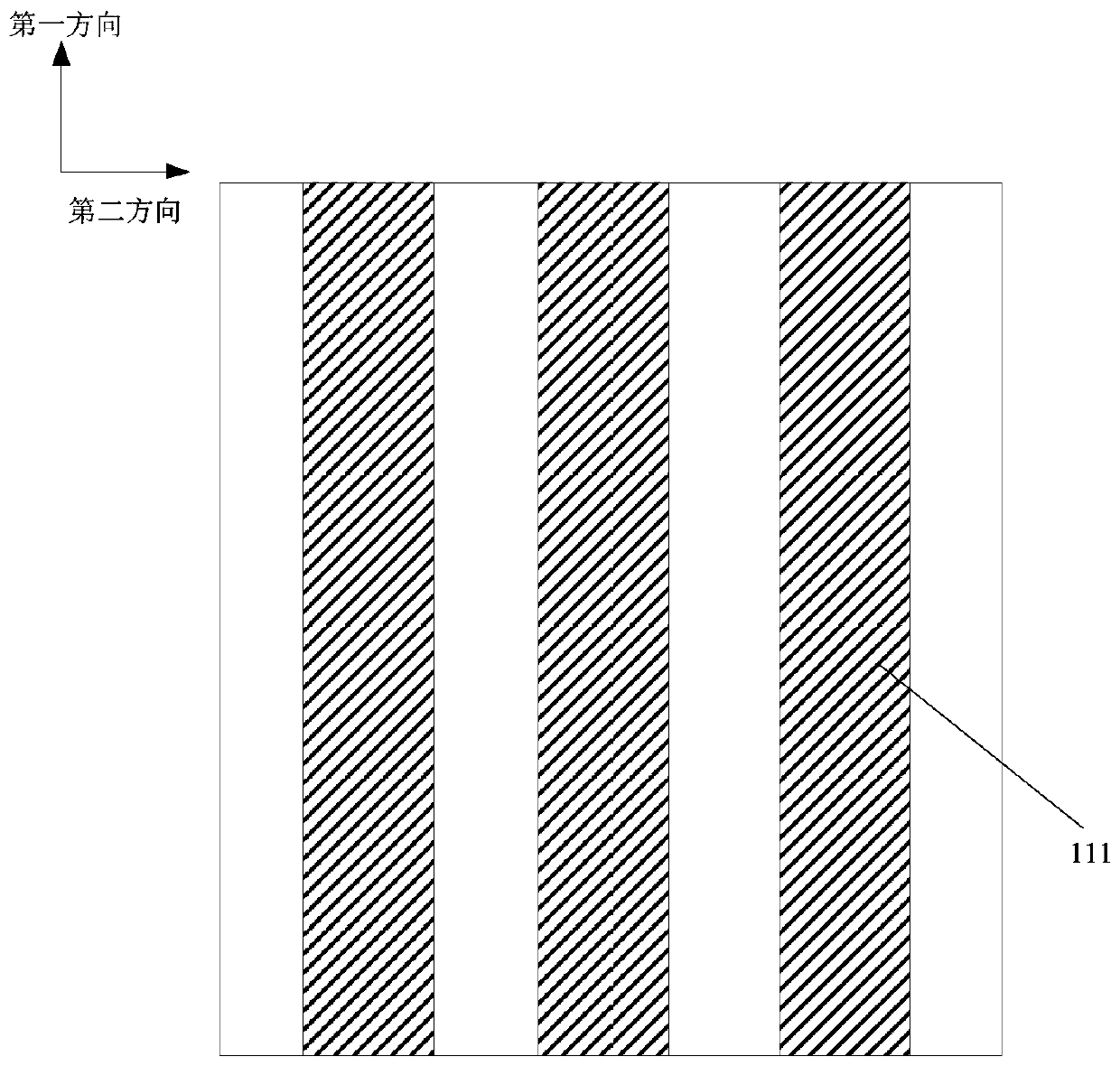

[0022] figure 1 A structural schematic diagram of an epitaxial structure of a III-nitride transistor provided by an embodiment of the present invention. Such as figure 1 As shown, the III-nitride transistor epitaxial structure 100 includes a substrate 110 and a nucleation layer 120, a buffer layer 130, a channel layer 140 and a barrier layer 150 stacked sequentially on the substrate; the substrate 110 includes multiple Each groove structure 111 and the growth window 112 between the groove structures 111; the nuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com