Combined regenerated heat energy exchanger

A heat exchanger and combined technology, applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc., can solve a lot of labor and other problems, and achieve the effects of saving maintenance costs, reducing lateral leakage, and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

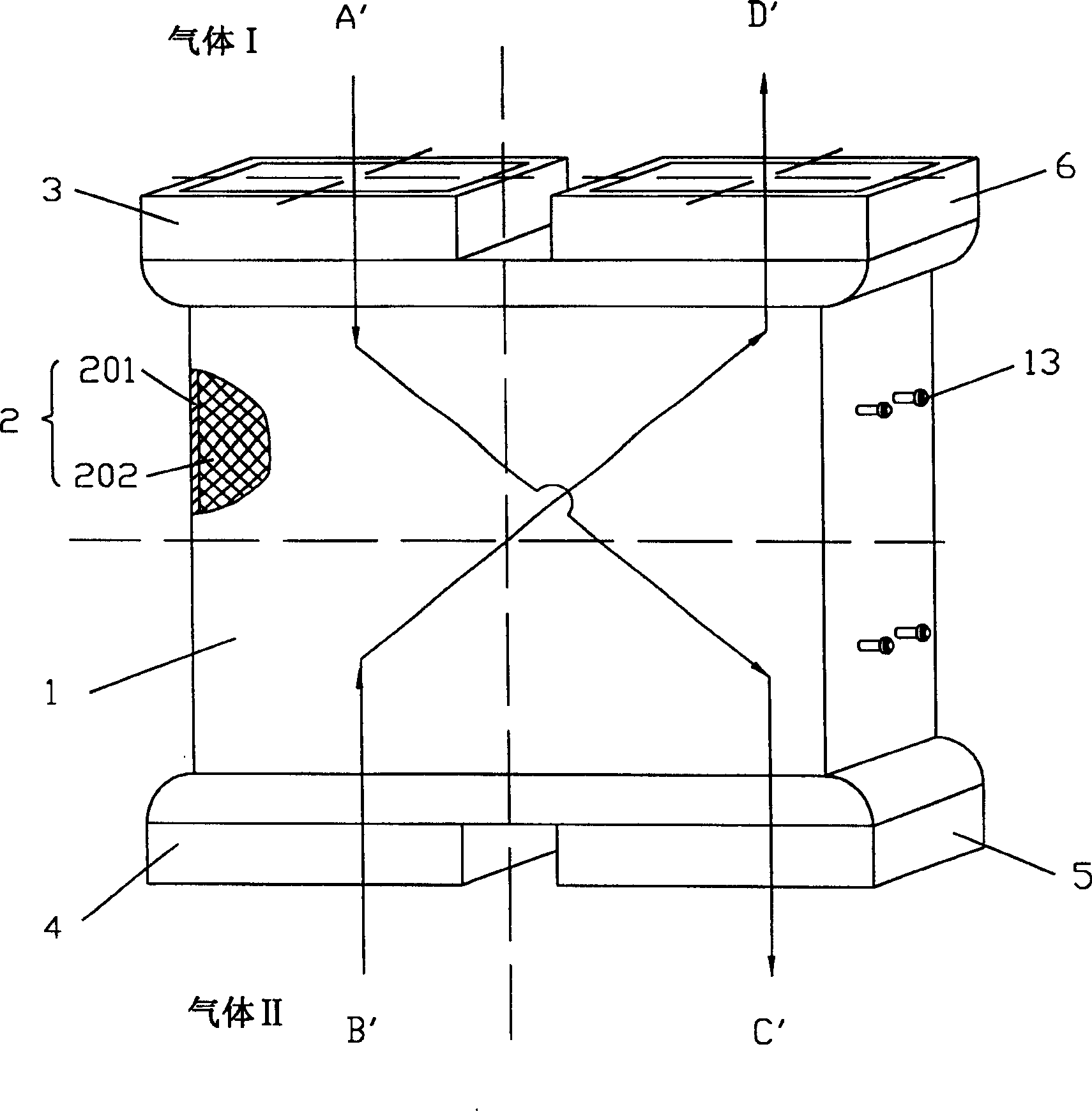

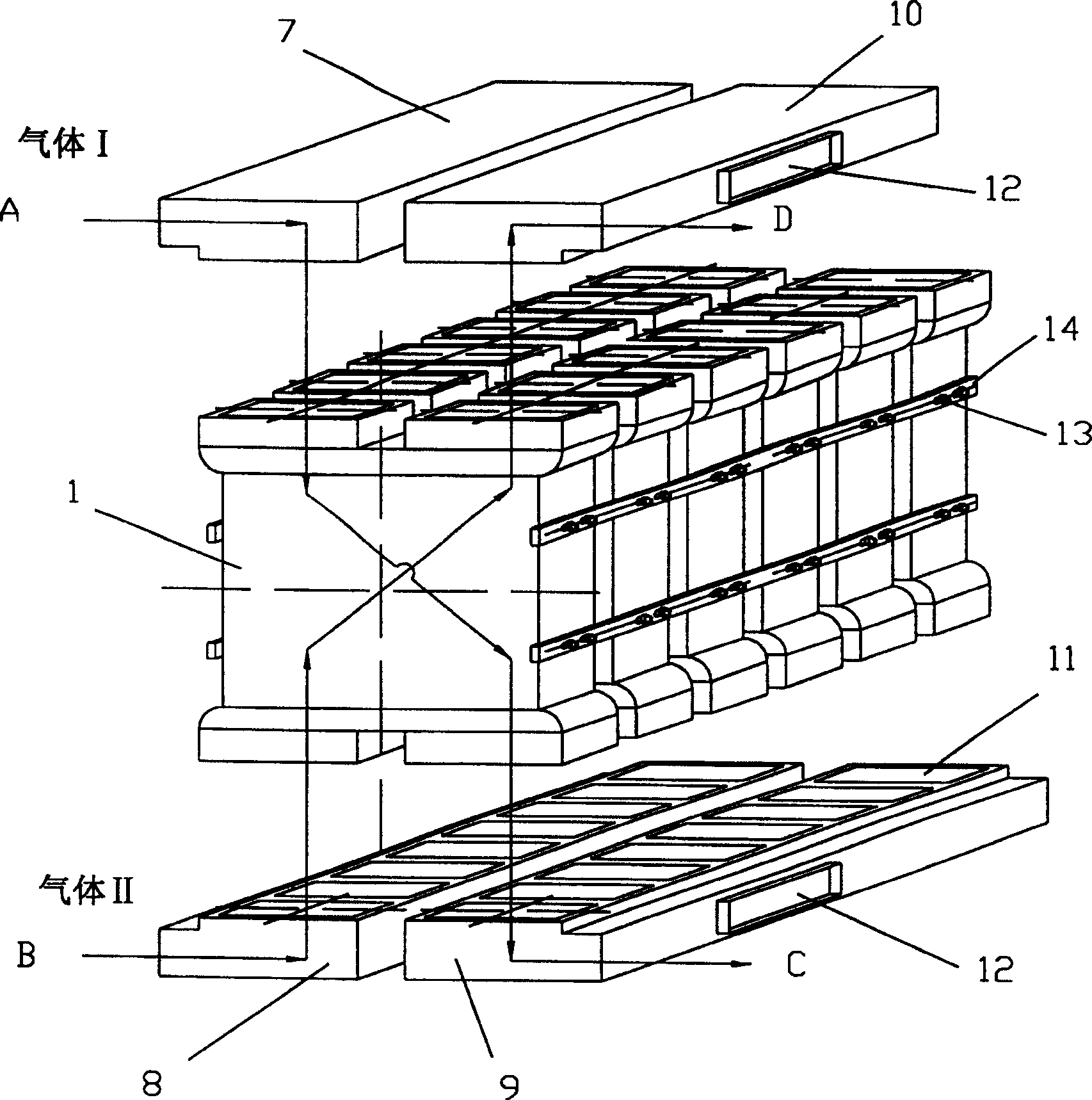

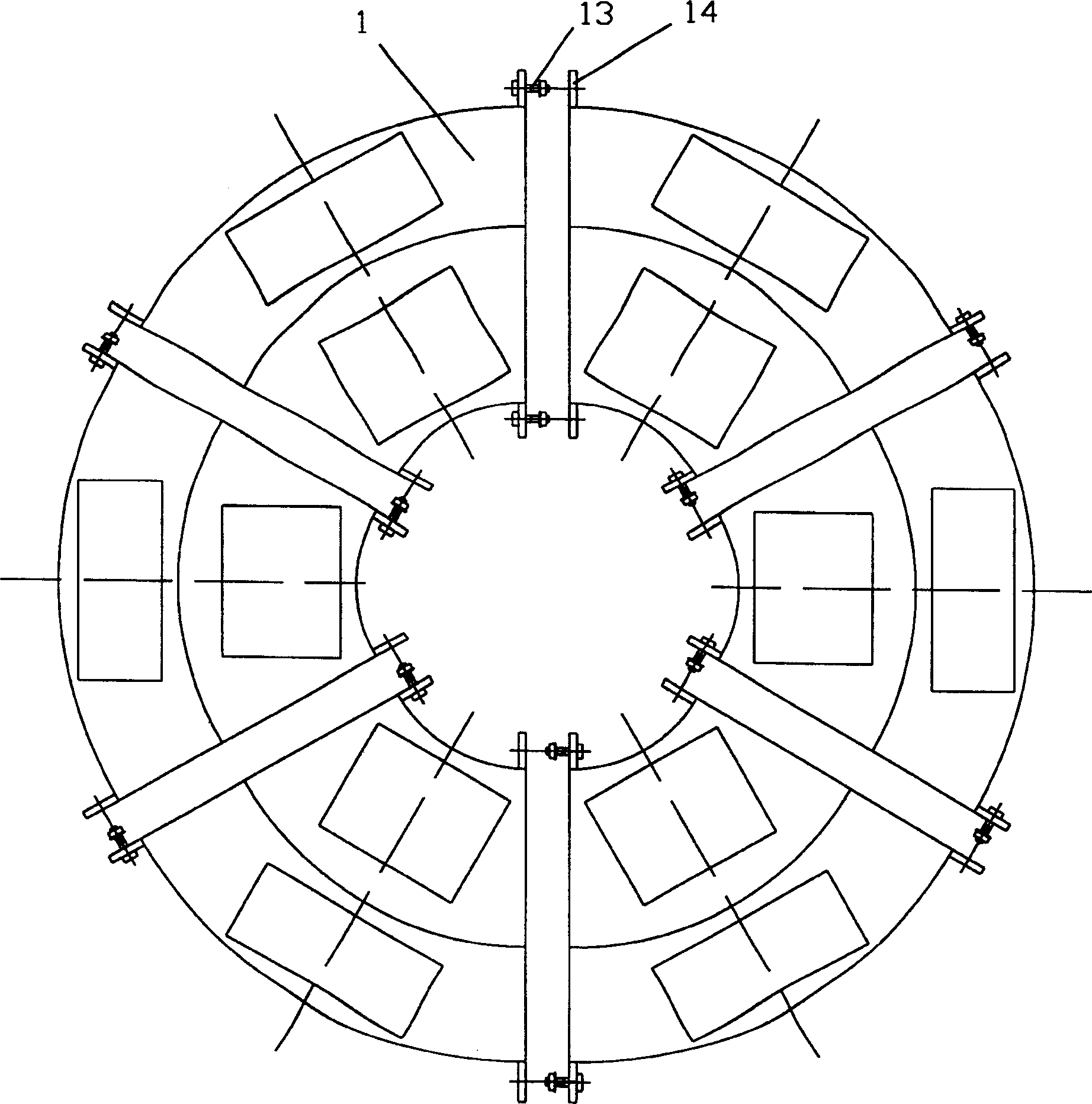

[0029] Please refer to figure 1 , figure 2 The present invention is a combined regenerative heat exchanger, which is composed of a number of mutually independent and interchangeable regenerative heat exchanger modules 1 connected to each other, and each regenerative heat exchanger module contains a packed bed 2. The shell 201 on the packed bed has four openings, and the inside of the packed bed is filled with endothermic materials 202. The openings of the packed bed are provided with inlet baffles 3, which control the flow of cold and hot gases (gas I and II). 4 and outlet baffles 5, 6. The inlet and outlet baffles 3, 4, 5, and 6 are in a sealed connection with the packed bed 2, and the gas inlet and outlet baffles 3, 4, 5, 6 and the gas inlet and outlet ducts 7, 8, 9, and 10 are sealed connections. The operation of the inlet and outlet baffles runs in sequence, so that hot gas and cold gas alternately flow through the endothermic material in the packed bed.

[0030] The inlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com