Open type cyclic tubular microbial dialysis cultivation system

An open circulation and culture system technology, applied in the field of open circulation tubular microbial dialysis incubator system, can solve the problems of incompatibility, cumbersome loading and unloading process, and rare equipment, so as to improve the harvest rate and save electric energy and water consumption , The effect of reducing the labor intensity of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

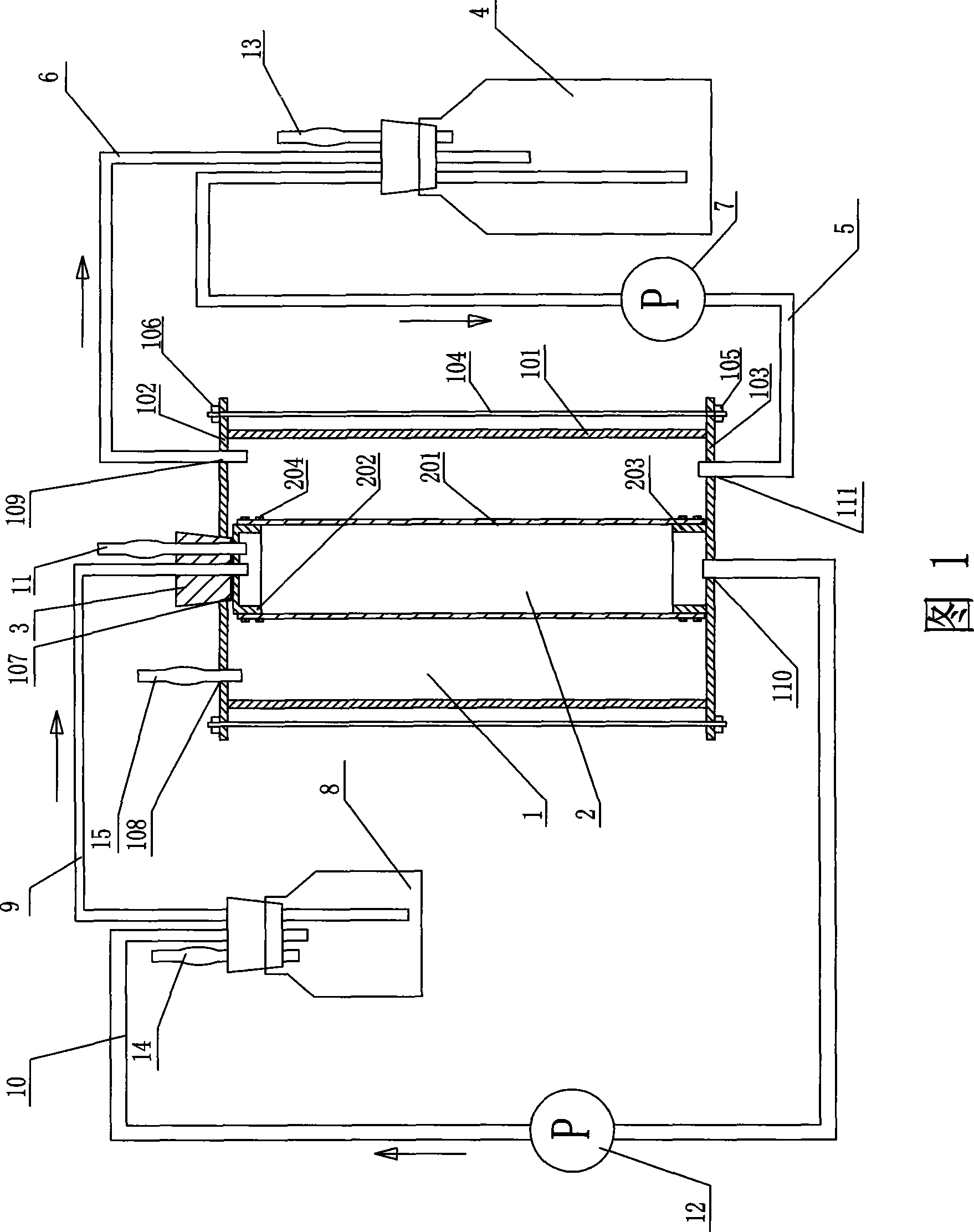

[0018] As shown in Figure 1, the hollow cylindrical medium chamber 1 of the present invention is made up of a hollow cylindrical column wall 101 and upper and lower two covers 102, 103, and the two ends of the column wall 101 are arranged on the upper and lower covers respectively. Between the bodies 102 and 103 , and between the upper and lower cover bodies 102 and 103 are fixedly connected to each other through studs 104 and nuts 105 and 106 . The column wall 101 can be made of transparent material or stainless steel material with sight glass.

[0019] The hollow cylindrical microbial dialysis culture chamber 2 is composed of a tubular dialysis membrane 201 and upper and lower stainless steel covers 202, 203. 203 on. And, the lower end of the lower stainless steel ring 203 is welded on the lower cover 103 of the cylindrical medium chamber.

[0020] The microorganism dialysis cultivation chamber 2 is arranged in the middle of the culture medium chamber 1, and the volume rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com