Cold punching processing method for gear face oil groove

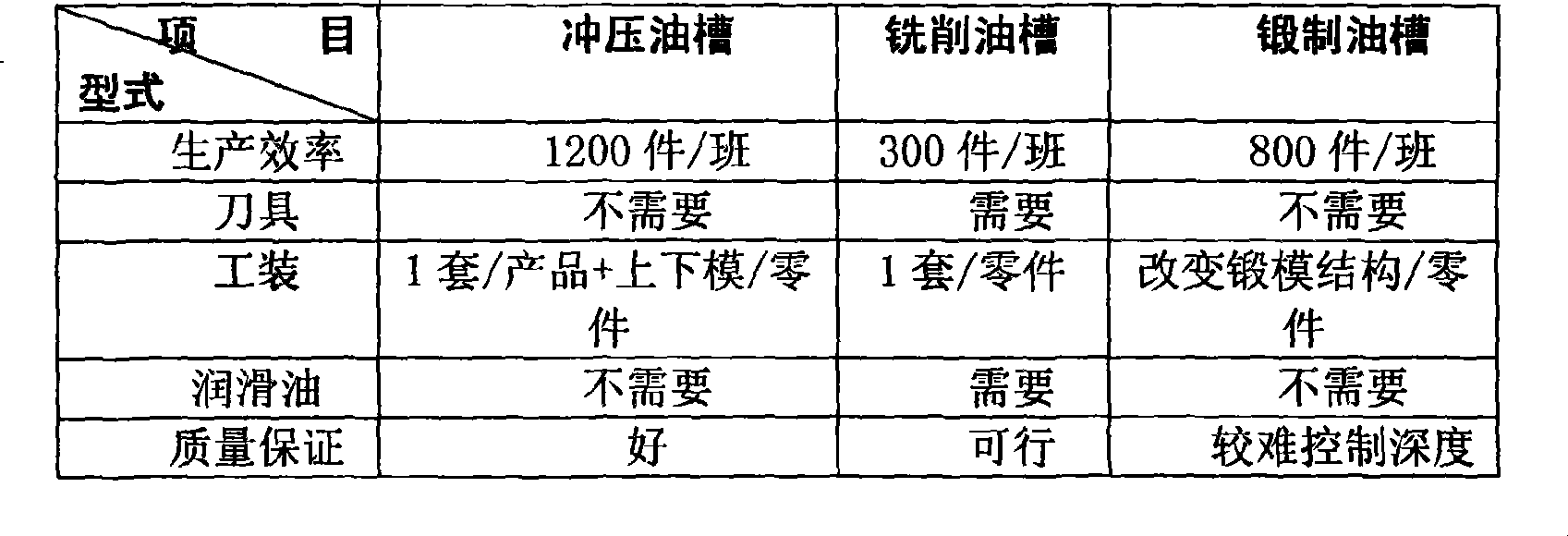

A processing method and gear end technology, which are applied in the field of cold stamping of oil grooves on gear end faces, can solve the problems of processing difficulty, tool wear, and difficulty in ensuring the depth and width of oil grooves, and achieve the effects of reducing processing, ensuring quality and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] 1. Due to the stamping deformation of the inner hole after stamping, the cold punching oil tank process is arranged after the rough turning gear end face, and before the finish turning gear inner hole and end face. After the rough turning of the gear end face, the oil groove on the gear end face is directly punched out with a mold, and then the inner hole and end face of the gear are finished, that is, the cold punching process of the oil groove on the gear end face is completed, and then enters the next process of broaching the inner hole.

[0008] 2. Design principle of oil groove on gear end face:

[0009] a. The depth of the oil groove on the end face of the gear is 1±0.2, and the depth of the oil groove on the end face of the cold stamping gear is 1.7±0.1 (including the margin of 0.6 on the end face of the finishing car and 0.1 of the margin on the grinding end face);

[0010] b. Obtained from experience: the oil grooves on the gear end surface below φ50 are symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com