Withdrawal roll device of end trimming shear

A technology of pinch rollers and trimming shears, which is applied in the field of pinch equipment before and after trimming and shearing, can solve the problems of poor linear speed of roller surfaces, marks of handover dislocation, affecting the shape and quality of steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

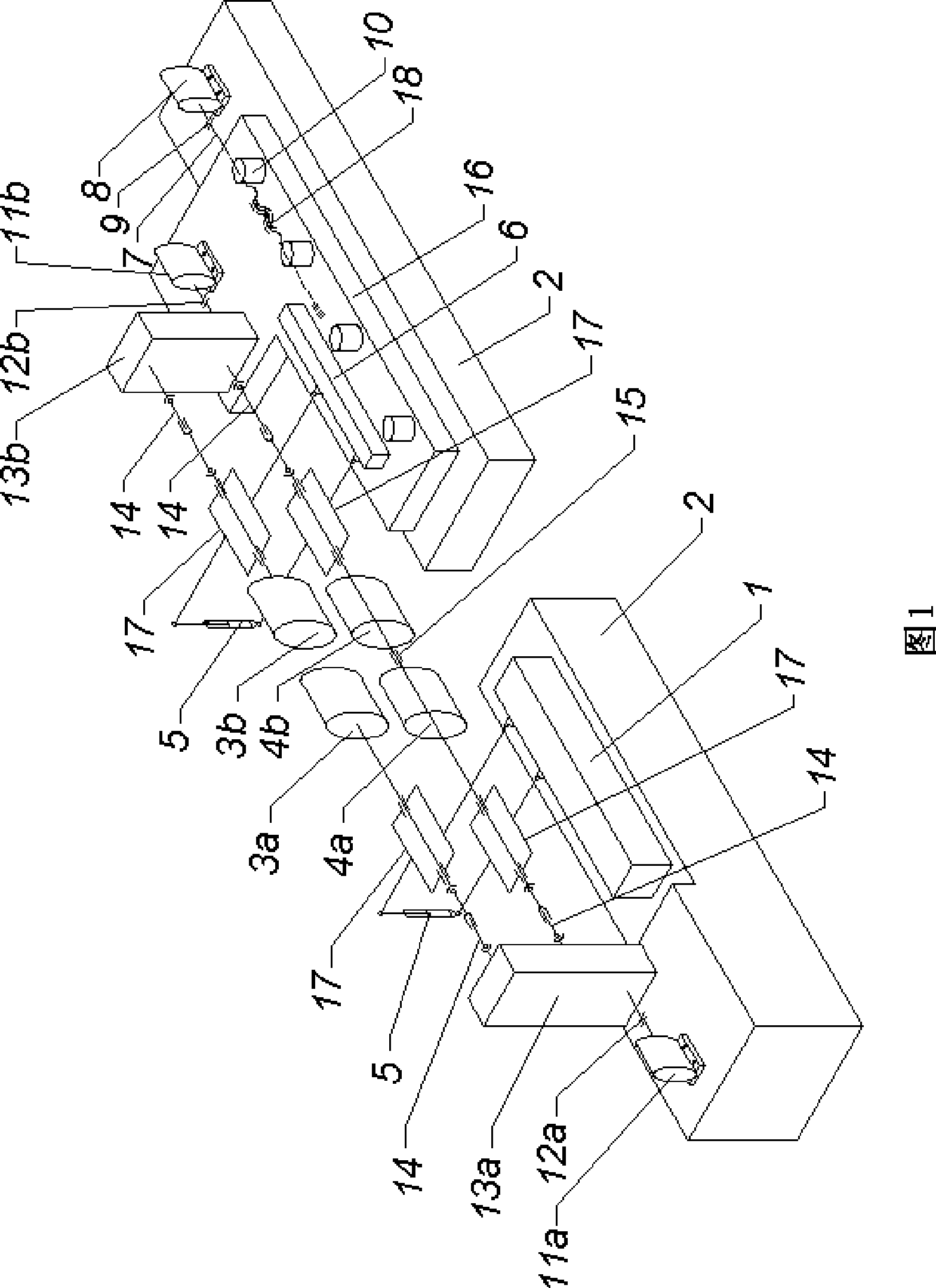

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] The trimming shear pinch roller device as shown in Figure 1, comprises the upper pinch roller 3a of the fixed side, the lower pinch roller 4a of the fixed side, the upper pinch roller 3b of the moving side, the lower pinch roller 4b of the moving side, the lower pinch roller of the fixed side The pinch roller 4a and the lower pinch roller 4b on the moving side are axially connected by a synchronous shaft 15, the upper pinch roller 3a on the fixed side and the lower pinch roller 4a on the fixed side are synchronously driven by the transmission mechanism, and the upper pinch roller on the moving side 3b and the lower pinch roller 4b on the moving side are synchronously driven by a transmission mechanism. The pinch roller 3a on the fixed side and the lower pinch roller 4a on the fixed side are two upper and lower pinch rollers relative to each other, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com