Device for threading a processing installation, such as a dryer

A technology for processing facilities and dryers, applied in the direction of textiles and papermaking, paper machines, paper machine wet ends, etc., to achieve the effect of reducing the risk of failure in the feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

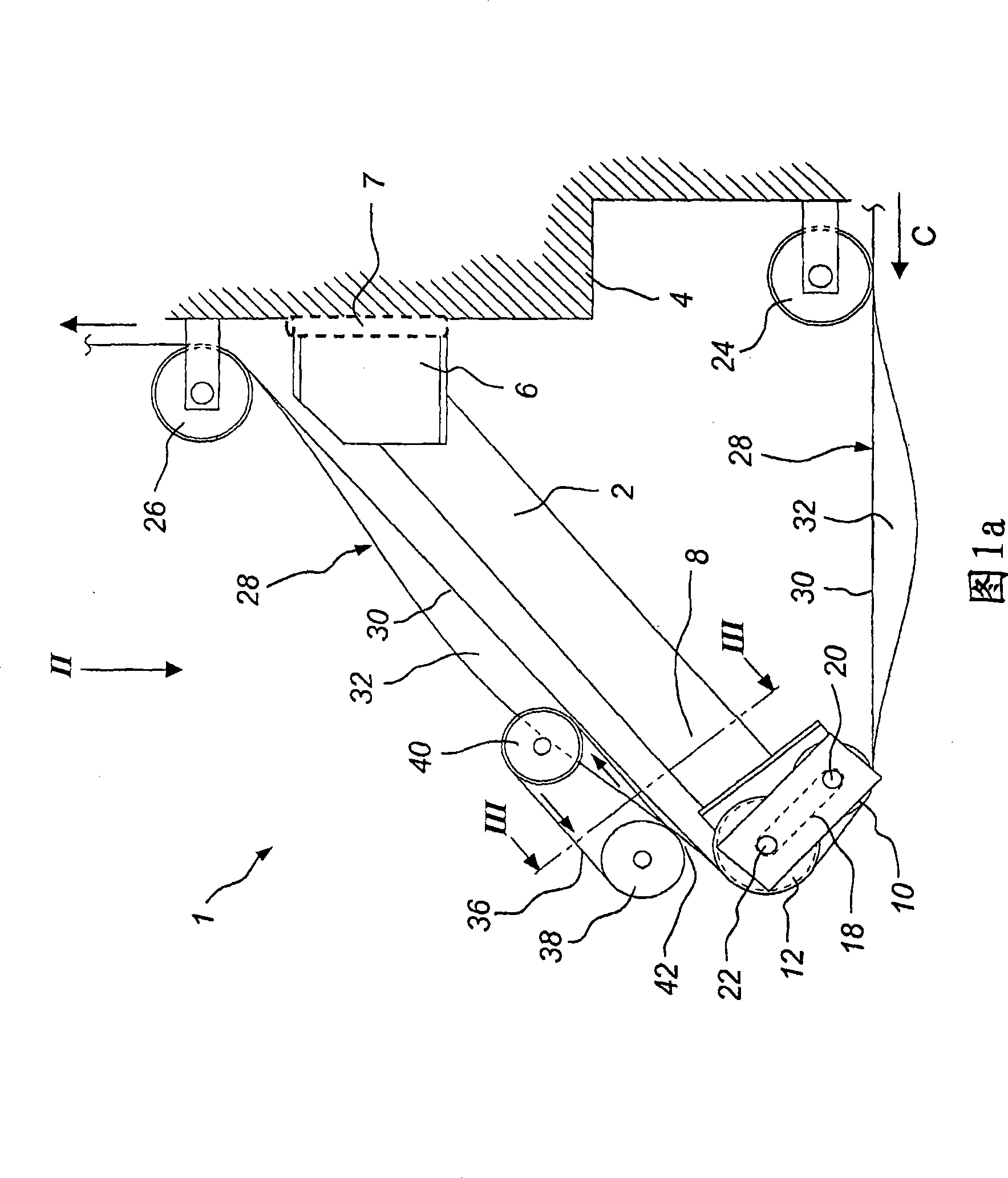

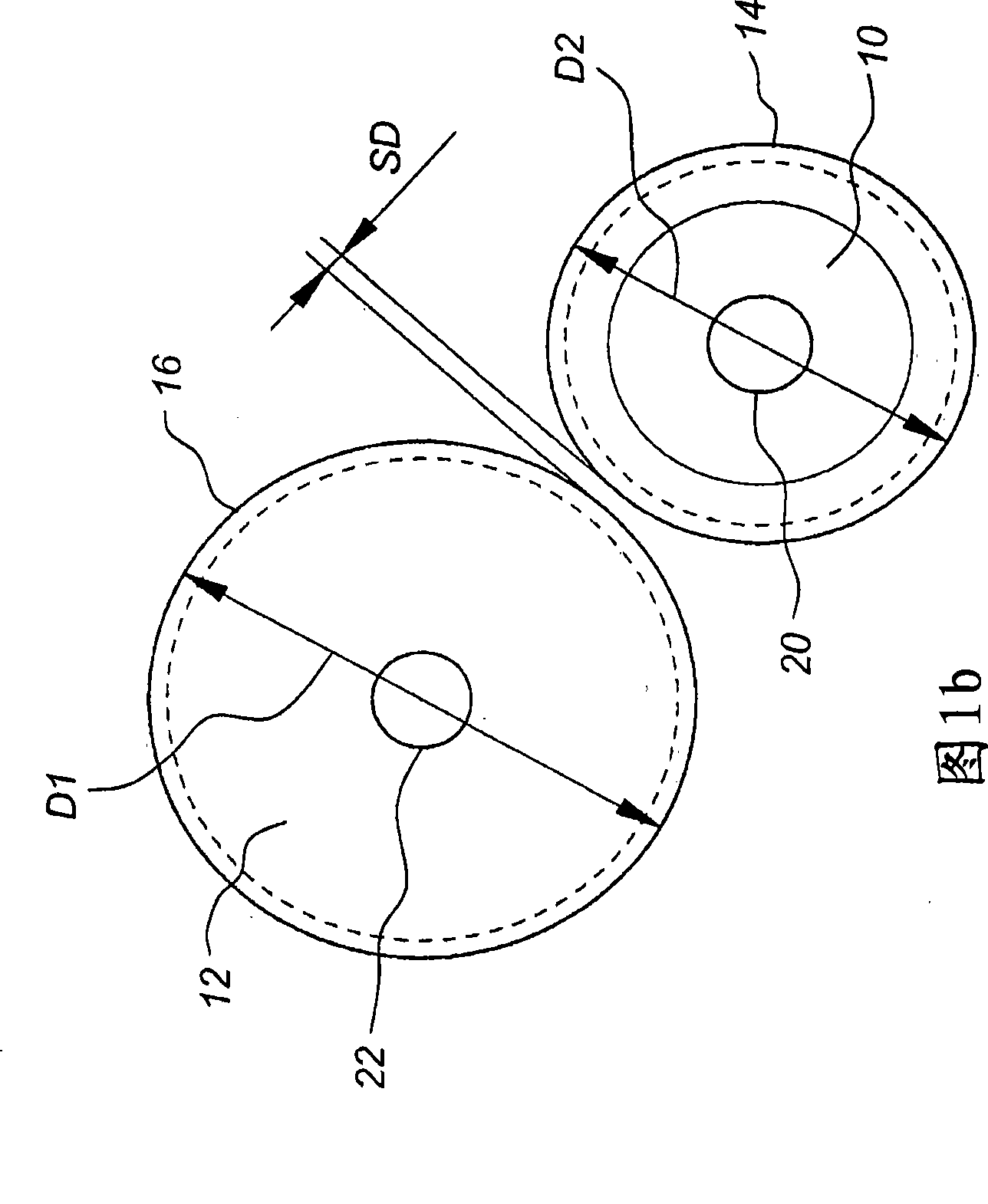

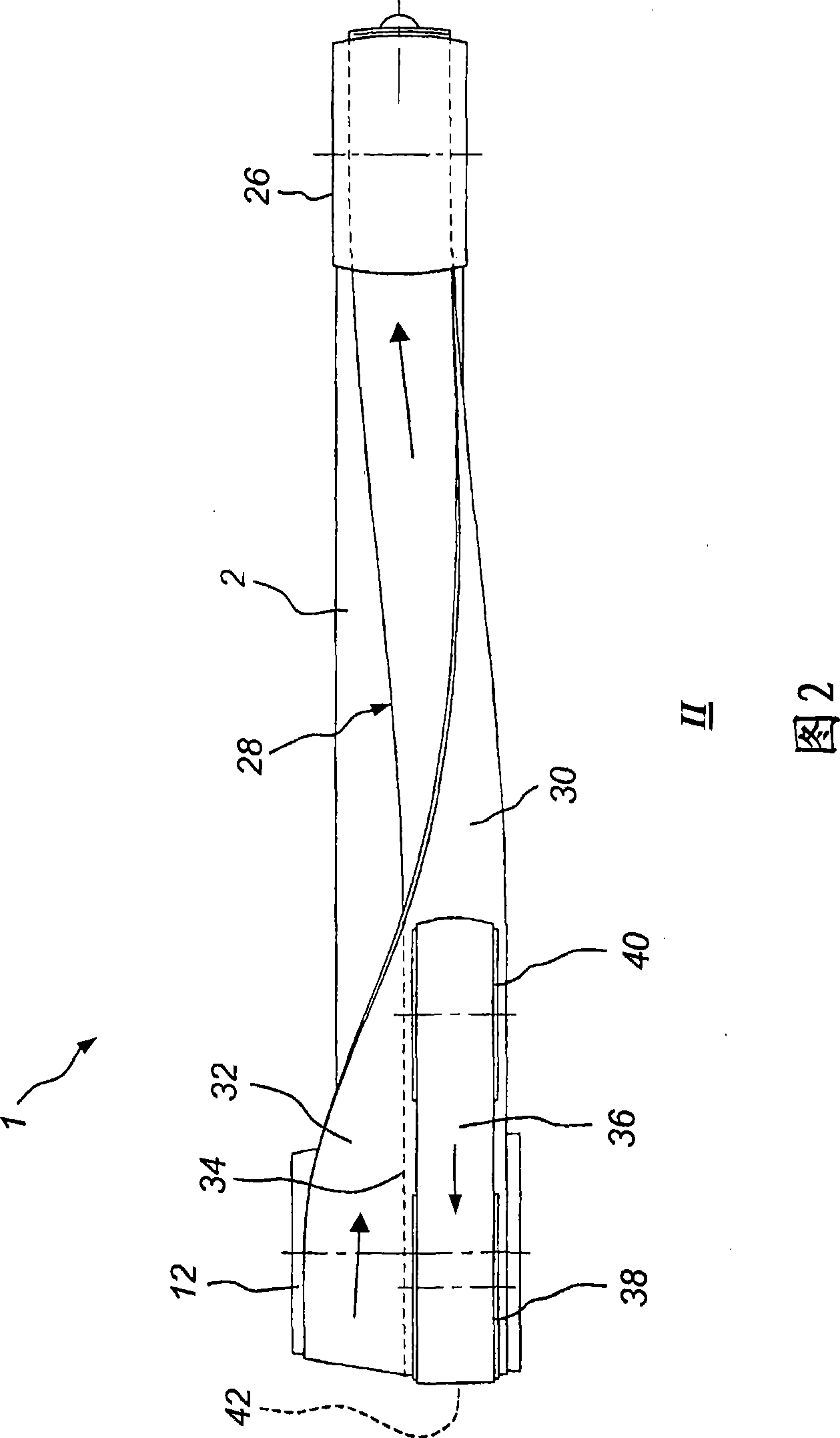

[0026] Figure 1a shows a tail conveyor 1, seen from the side, for conveying a tail of paper web material through a processing facility, such as a dryer, not shown. FIG. 1 b is an enlarged schematic side view and shows certain details of the tail conveyor 1 . FIG. 2 shows the tail conveyor 1 seen from above, ie in the direction of arrow II in FIG. 1a. The tail conveyor 1 is useful, for example, for feeding a fibrous pulp web through a pulp dryer of the Andritz Pulp Dryer type. The process of feeding a tail through a processing facility, such as a dryer, is generally referred to as passing through the processing facility. The tail conveyor 1 comprises a tail conveyor bar 2 supported on a structure 4 . As shown in FIG. 1 a, the tail transfer bar 2 is provided with a fixing element 6 which fixes the tail transfer bar 2 to the structure 4 . As an option, the fixing element 6 can be provided with a hinge 7, so that the tail transfer bar 2 is pivotable in the horizontal plane. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com