Real-time diagnosis method for random vibration fault of steam generator set

A turbo-generator set, random vibration technology, applied in vibration testing, engine testing, machine/structural component testing, etc., can solve the problems of long cycle, poor effectiveness, fatigue damage of corrugated joints, etc., and achieve scientific methods and conclusions. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

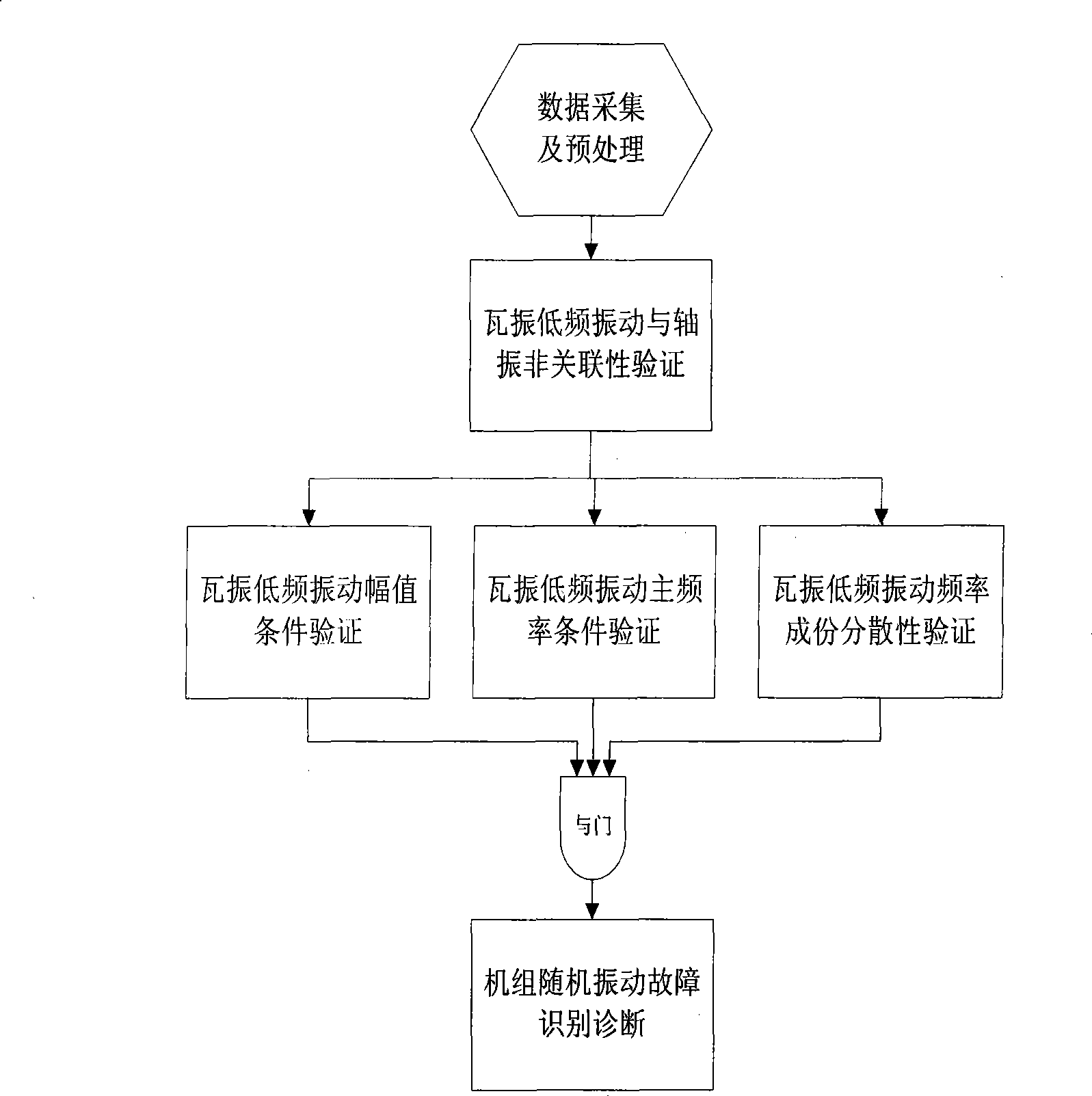

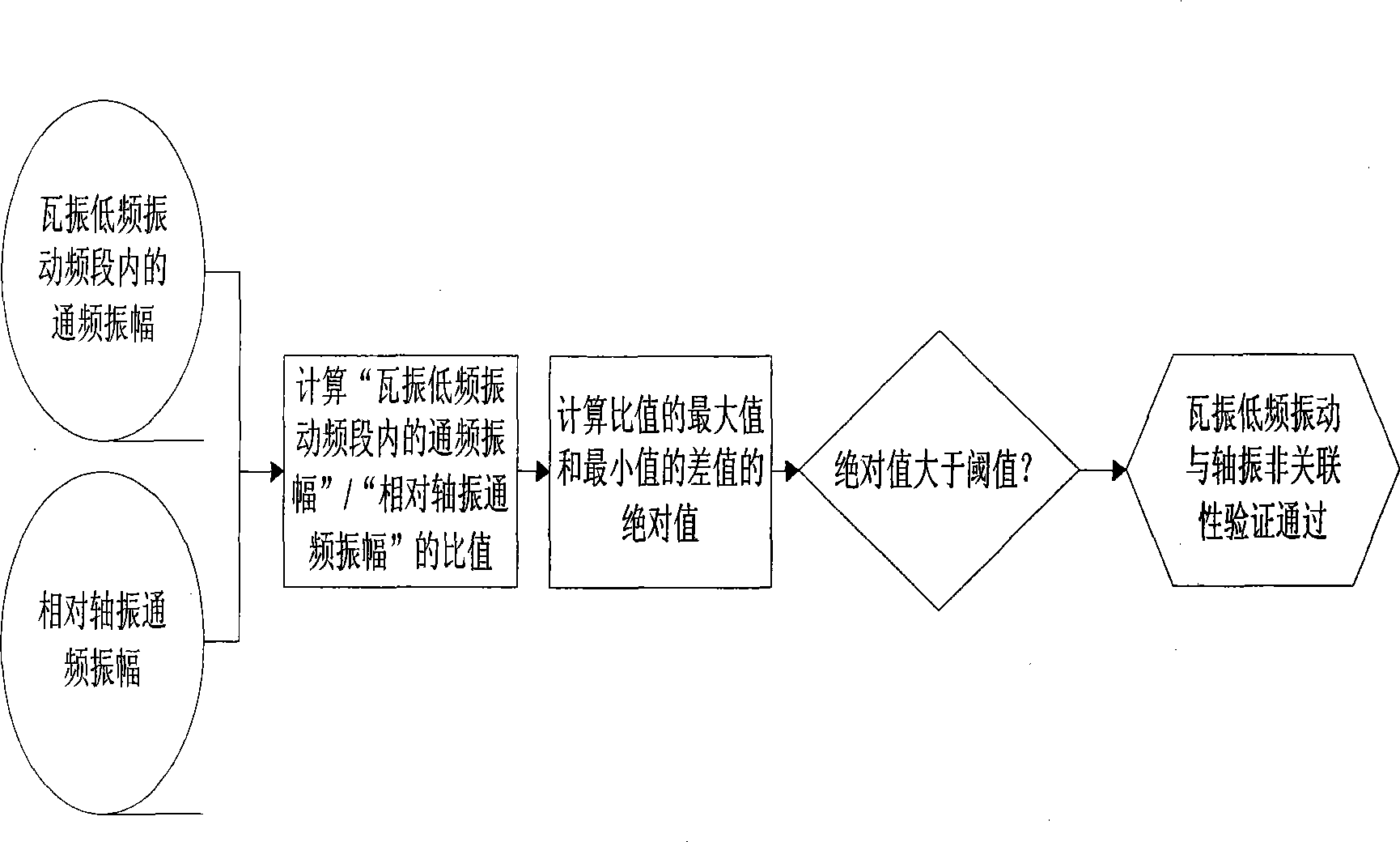

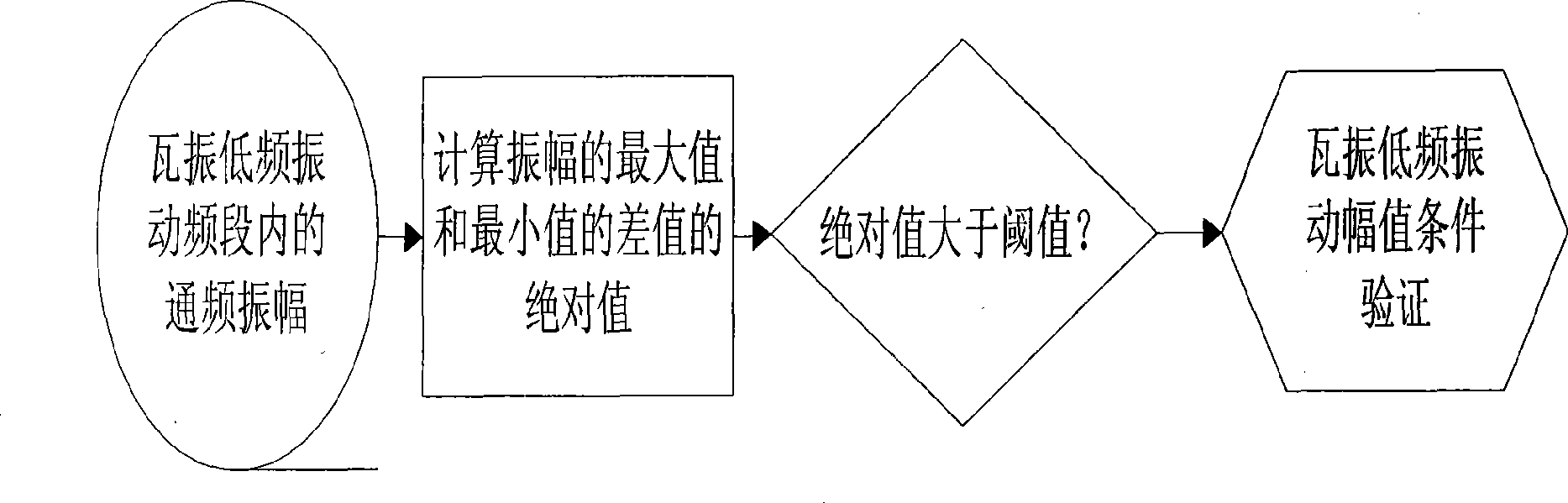

[0039] Using this method, the random vibration fault diagnosis of the bearing seat on the high-voltage rotor side of the 300MW turbogenerator set can be realized. According to this method, a specific random vibration fault computer diagnosis program is designed, and the fault diagnosis program is installed in the industrial computer (IPC). A diagnostic cycle process in the real-time diagnostic program for random vibration faults includes data acquisition and preprocessing involved in the diagnostic method, verification of non-correlation between low-frequency vibration of tile vibration and shaft vibration, verification of low-frequency vibration amplitude conditions, verification of main frequency conditions of low-frequency vibration, A series of calculation, analysis and verification links such as low-frequency vibration frequency component dispersion verification, unit random vibration fault identification and diagnosis, etc.

[0040] First of all, the industrial computer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com