Hydrogenation reaction effluent air cooler tube bundle system used for chlorine-containing raw oil production

A hydrogenation reaction and effluent technology, applied in the petroleum industry, steam/steam condenser, hydrocarbon oil cracking, etc., can solve problems such as corrosion multiphase flow, erosion, etc., to improve economic benefits, reduce manufacturing costs, and benefit The effect of swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

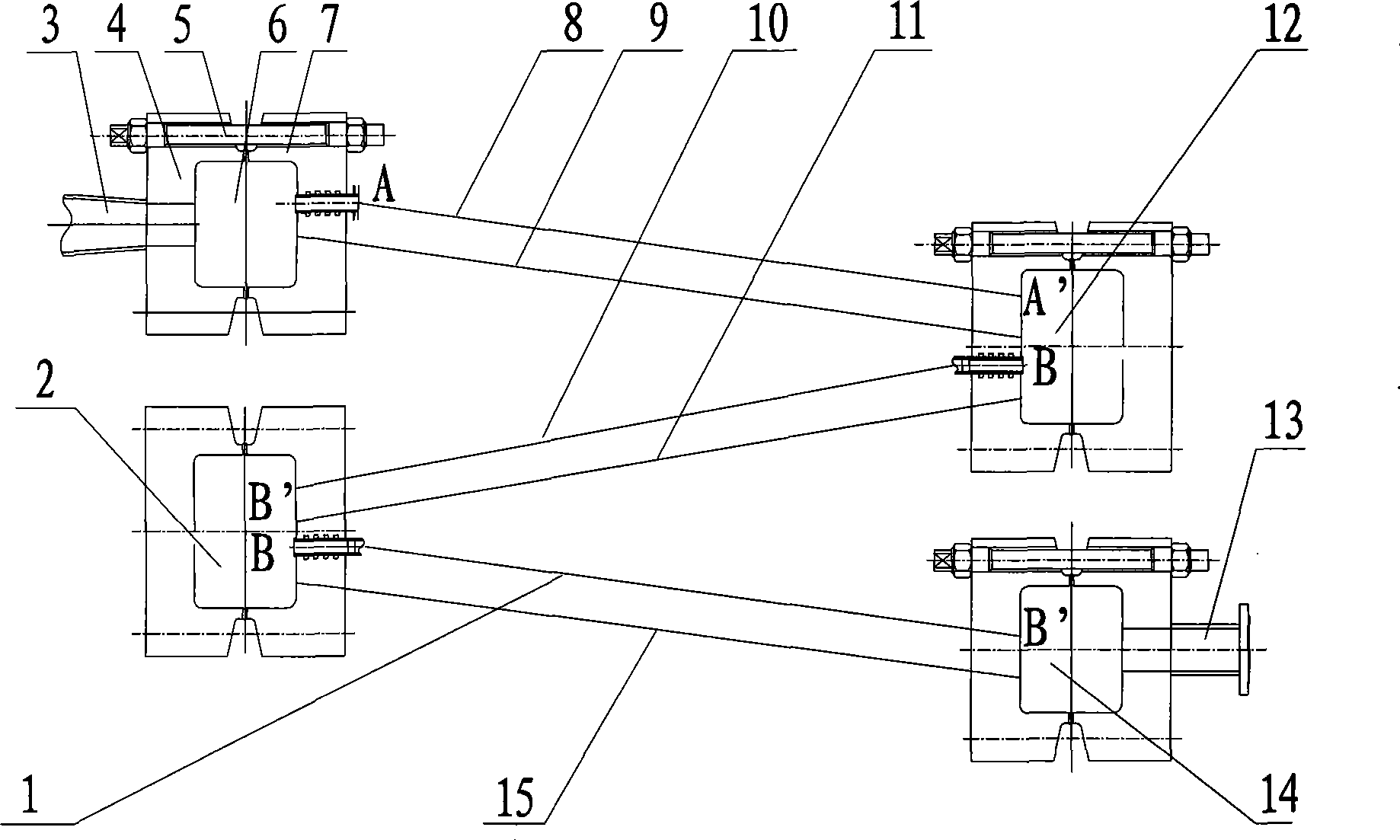

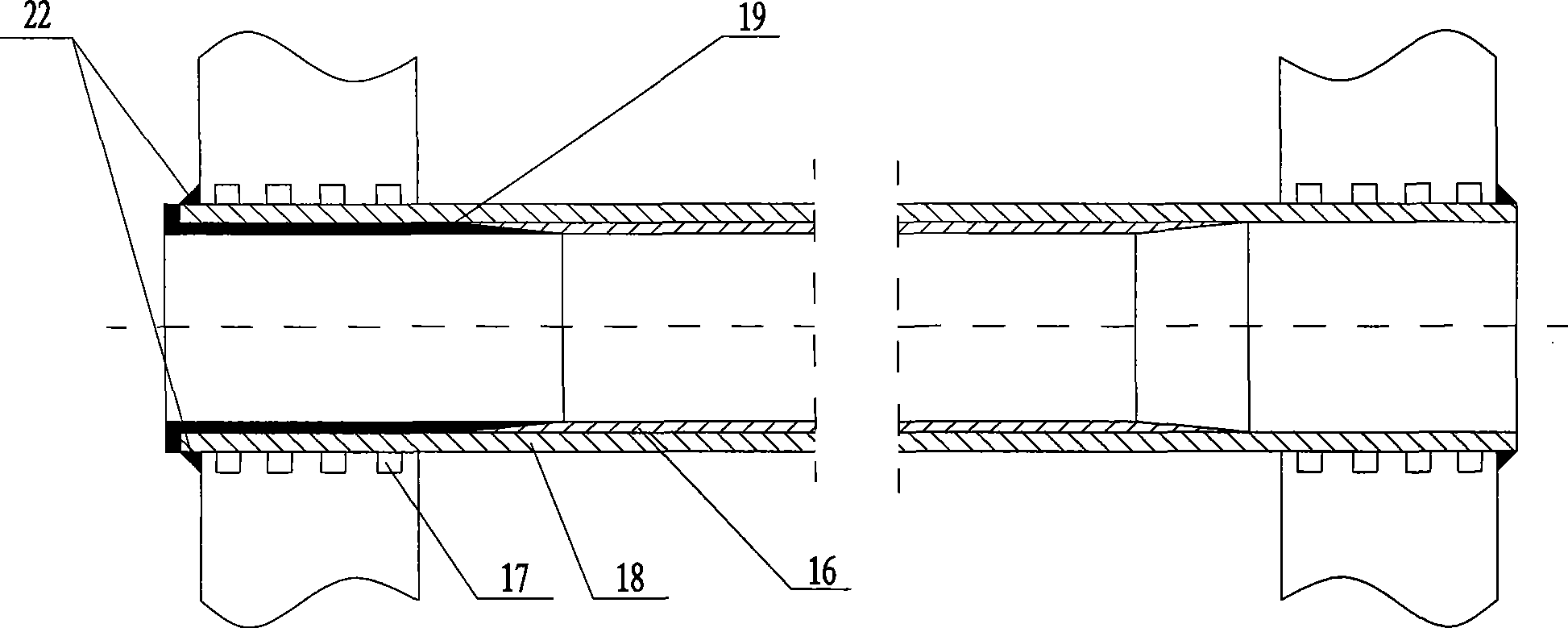

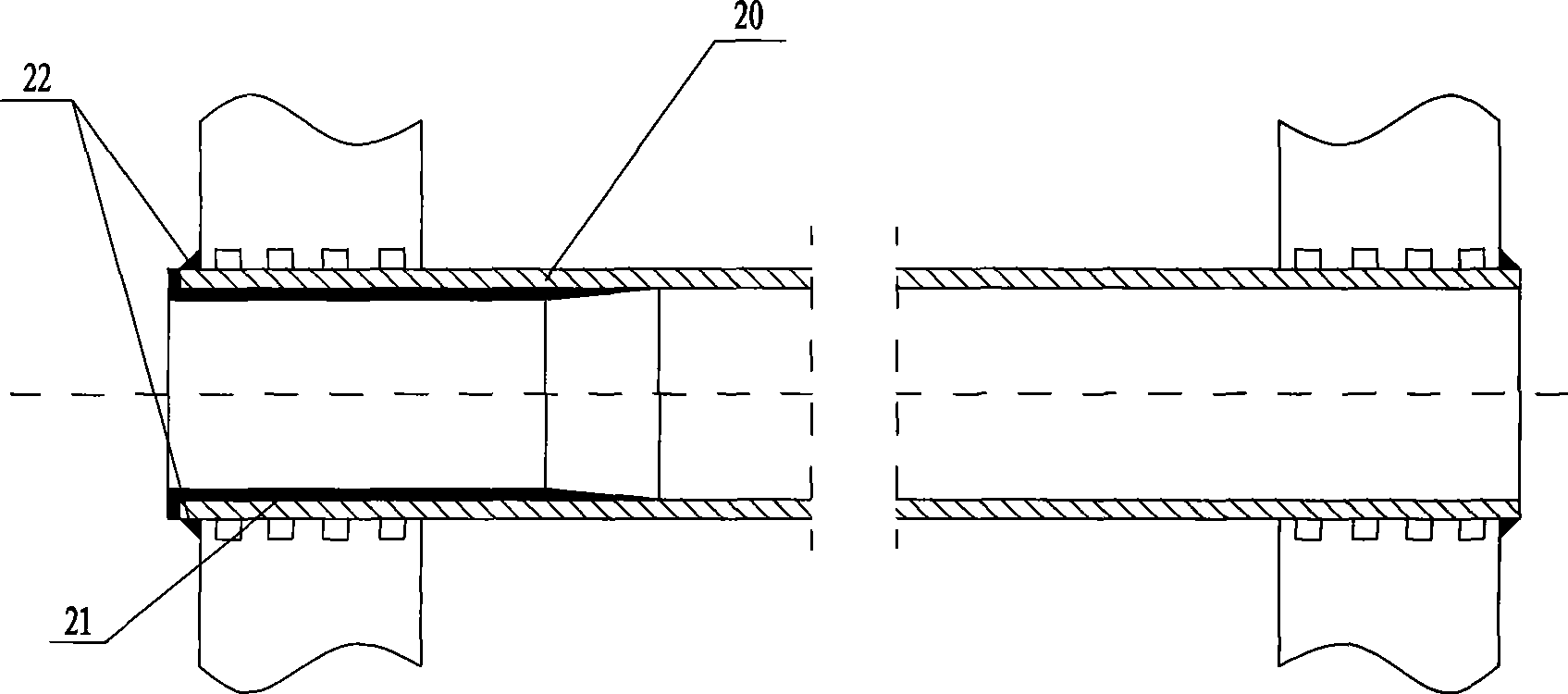

[0017] like figure 1 As shown, the hydrogenation reaction effluent air cooler tube bundle system applied to the processing of chlorine-containing feedstock oil includes a first tube box 6, a first tube bank 8, a second tube bank 9, a second tube box 12, a third tube Pipe bundle 10, fourth pipe bundle 11, third pipe box 2, fifth pipe bundle 1, sixth pipe bundle 15, fourth pipe box 14, reaction effluent inlet 3, reaction effluent outlet 13; The first tube bundle 8 and the second tube bundle 9 form the first tube pass, the third tube bundle 10 and the fourth tube bundle 11 form the second tube pass, the fifth tube bundle 1 and the sixth tube bundle 15 Form the third tube pass; the first tube box 6, the second tube box 12, the third tube box 2, and the fourth tube box 14 are composed of the outer tube box 4 and the inner tube box 7 through connecting bolts 5; the first tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com