Method for in-situ preparation of self-supporting gallium nitride underlay

A gallium nitride substrate, in-situ technology, applied in gaseous chemical plating, semiconductor/solid-state device manufacturing, coating, etc., can solve the problems of increasing cost and complexity, and achieve the effect of increasing cost and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

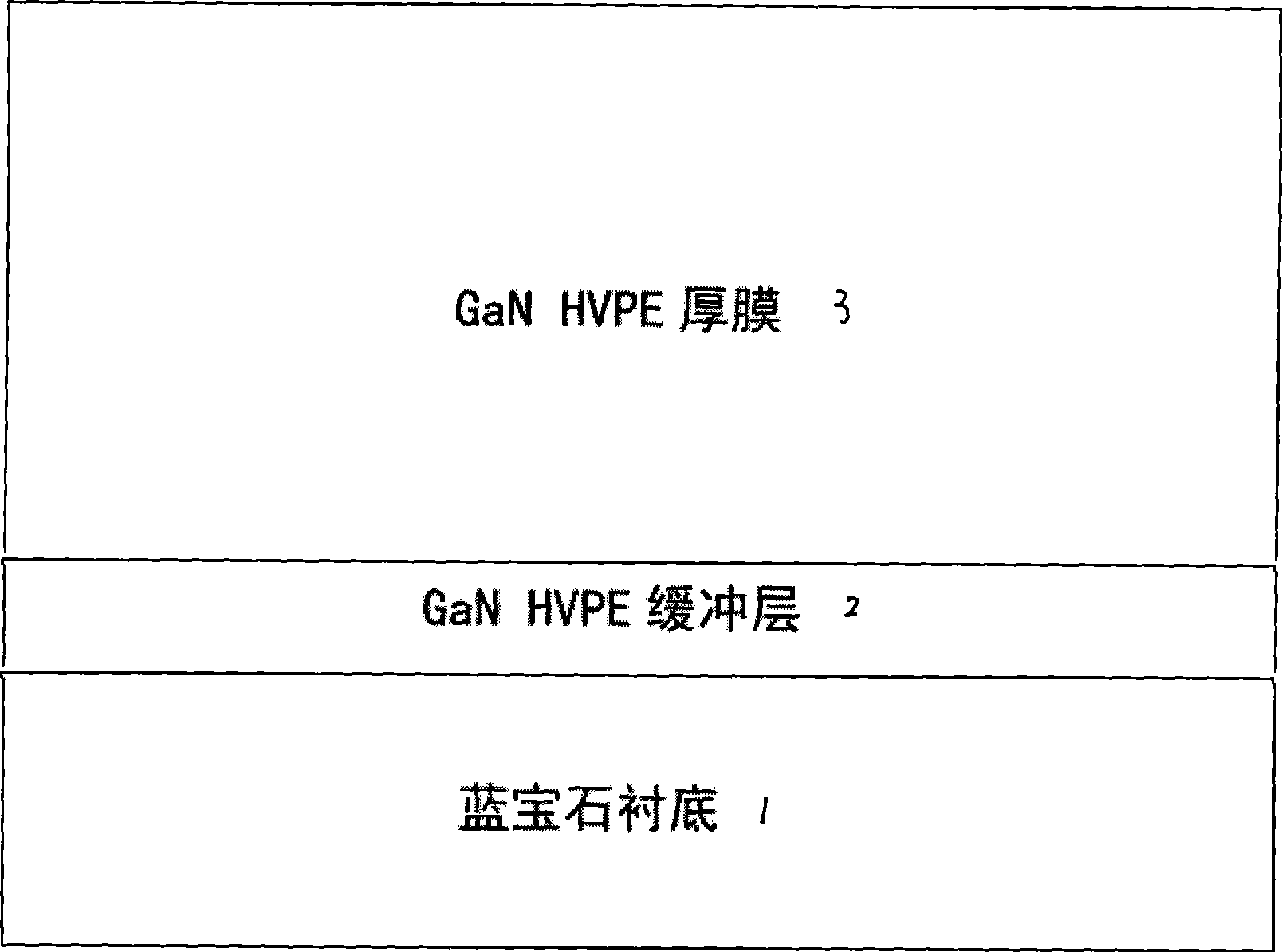

Image

Examples

Embodiment 1

[0021] Horizontal HVPE system, the growth temperature of the buffer layer is 700°C, and the growth time of the buffer layer is 1 minute. Buffer layer growth conditions, ammonia and HCl as gas source, NH 3 The flow rate is 1000 sccm, the ammonia carrier gas flow rate is 500 sccm, the HCl flow rate is 10 sccm, the HCl carrier gas flow rate is 200 sccm, and the total nitrogen gas flow rate is 1000 sccm. Raise the temperature to 1050°C to grow a GaN thick film for about 2 hours with a thickness of 200-300 microns. Growth conditions NH 3 The flow rate is 1000 sccm, the ammonia carrier gas flow rate is 500 sccm, the HCl flow rate is 20 sccm, the HCl carrier gas flow rate is 200 sccm, and the total nitrogen gas flow rate is 2500 sccm.

[0022] After the growth is completed, the temperature is lowered. The direct cooling method is adopted, and the cooling rate is about 10°C / min. The result is a GaN self-supporting substrate of nearly 2 inches and more than 200 microns thick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com