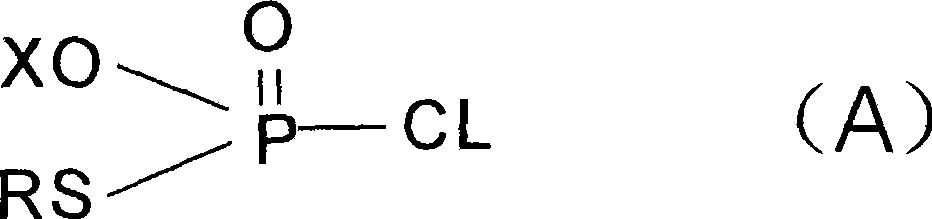

O,S-dimethyl thiophosphoryl chloride, preparation and uses thereof

A technology of dimethyl thiophosphoryl and methamidophos, which is applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc. Problems such as poor quality of amide and low yield of transisomerism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

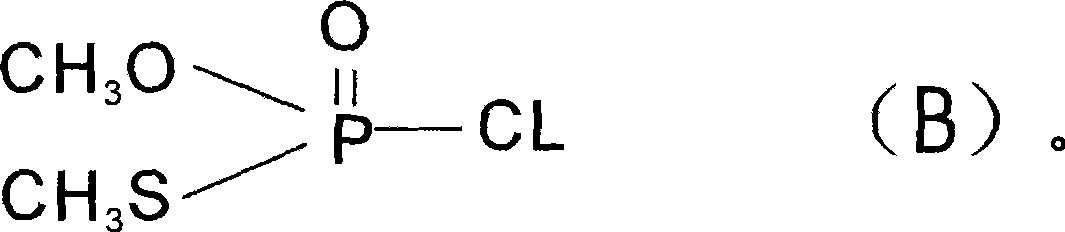

Method used

Image

Examples

Embodiment 1

[0027] Put 100 grams of anhydrous O, S-dimethylphosphorothiochloride with a content of 97% into a 500ml three-necked flask, and then put in 100 grams of benzene or toluene as a solvent, start stirring, slowly heat up to 65-80°C, drop Add 2 to 6 grams of CH 3 I reagent, or pass through dry CH 3 CL gas, stirred and reacted for 6 to 8 hours, then, maintained the temperature at 70°C to 77°C, slowly added 20 grams of anhydrous methanol reagent dropwise, and continued to stir and react for 8 hours until the HCL gas did not continue to overflow, that is It is the end point of the reaction, then lower the temperature to 20-40°C, stop stirring, put the reaction material liquid into the separatory funnel, let it stand for 30 minutes, and separate the lower liquid, which is O, S-dimethylphosphoryl thiochloride product , had a weight of 94 grams, and a content of 92% to 95%.

Embodiment 2

[0029] Put 100 grams of anhydrous O, O-dimethylphosphorylthiochloride with a content of 91% into a 500ml three-necked flask, and put 100 grams of toluene as a solvent, start stirring, slowly heat up to 75-90°C, and drop 2 ~6 grams (CH 3 ) 2 SO 4 , stirred and reacted for 6-8 hours, cooled to 20-40°C, allowed to stand for 30 minutes to separate layers, and separated the lower liquid, which was O, S-dimethylphosphoryl thiochloride, with a weight of 86 grams and a content of 85%- 90%.

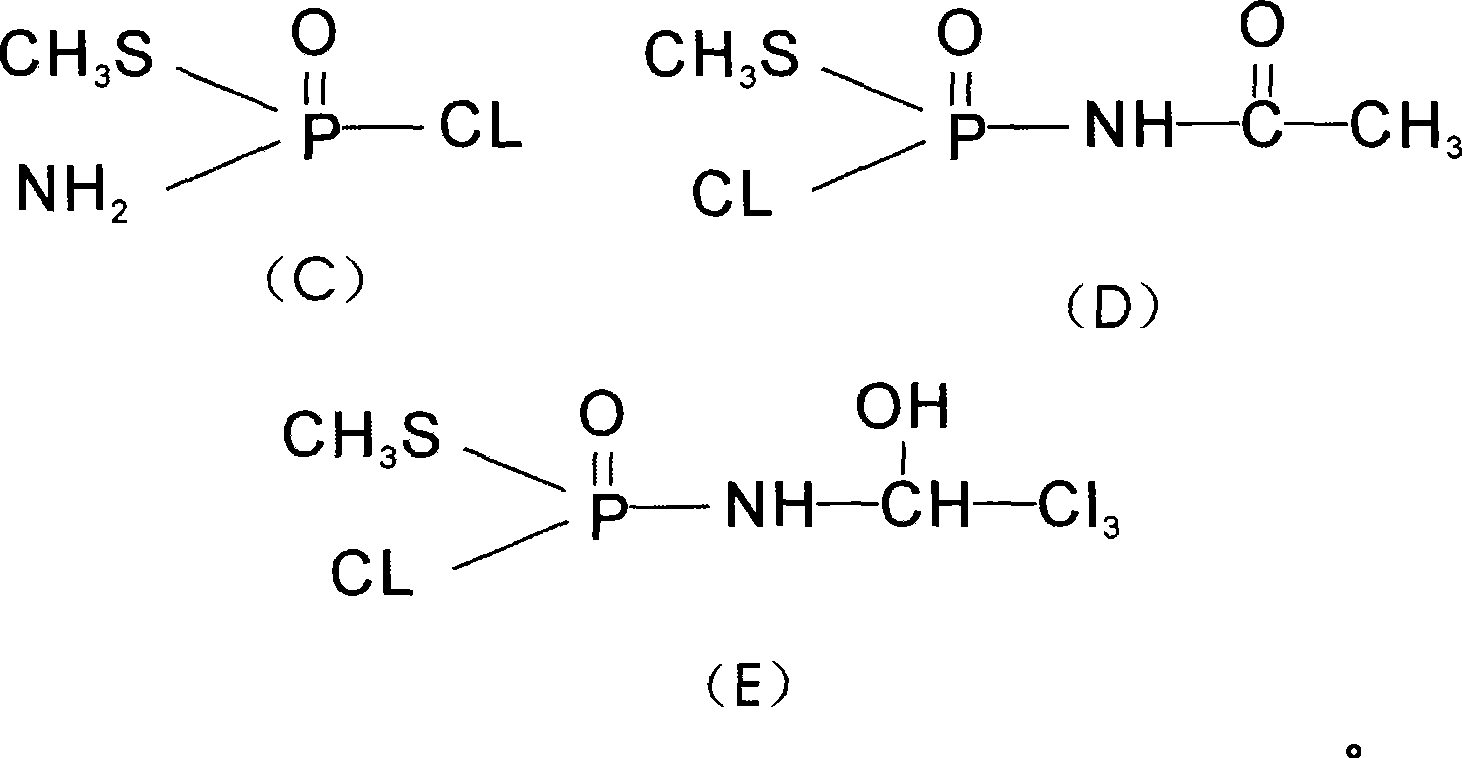

Embodiment 3

[0031] Put 100 grams of 95% anhydrous O, S-dimethylphosphoryl thiochloride into a 500ml three-necked flask, add 100 to 200 grams of dichloroethane as a solvent, start stirring, and 0 Slowly feed ammonia gas at ~40°C, analyze by gas chromatography, test that the content of O, S-dimethylphosphoryl thiochloride in the test reaction system is less than 0.5%, which is the end of the reaction, and filter out NH at room temperature 4 Cl is solid, then the mother liquor is evaporated to remove the dichloroethane solvent, evaporated to dryness as much as possible, and the distillation bottom is cooled to below 10°C to obtain a solid of methamidophos (chemical name O, S-dimethylphosphorothioate), It weighs 92 grams and has a content of 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com