Explosion prevention type terminal kit for cable coupling

A cable connection, explosion-proof technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of terminal box explosion, air deterioration, foreign matter entry, etc., to avoid explosion, ensure safety, and reliable insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

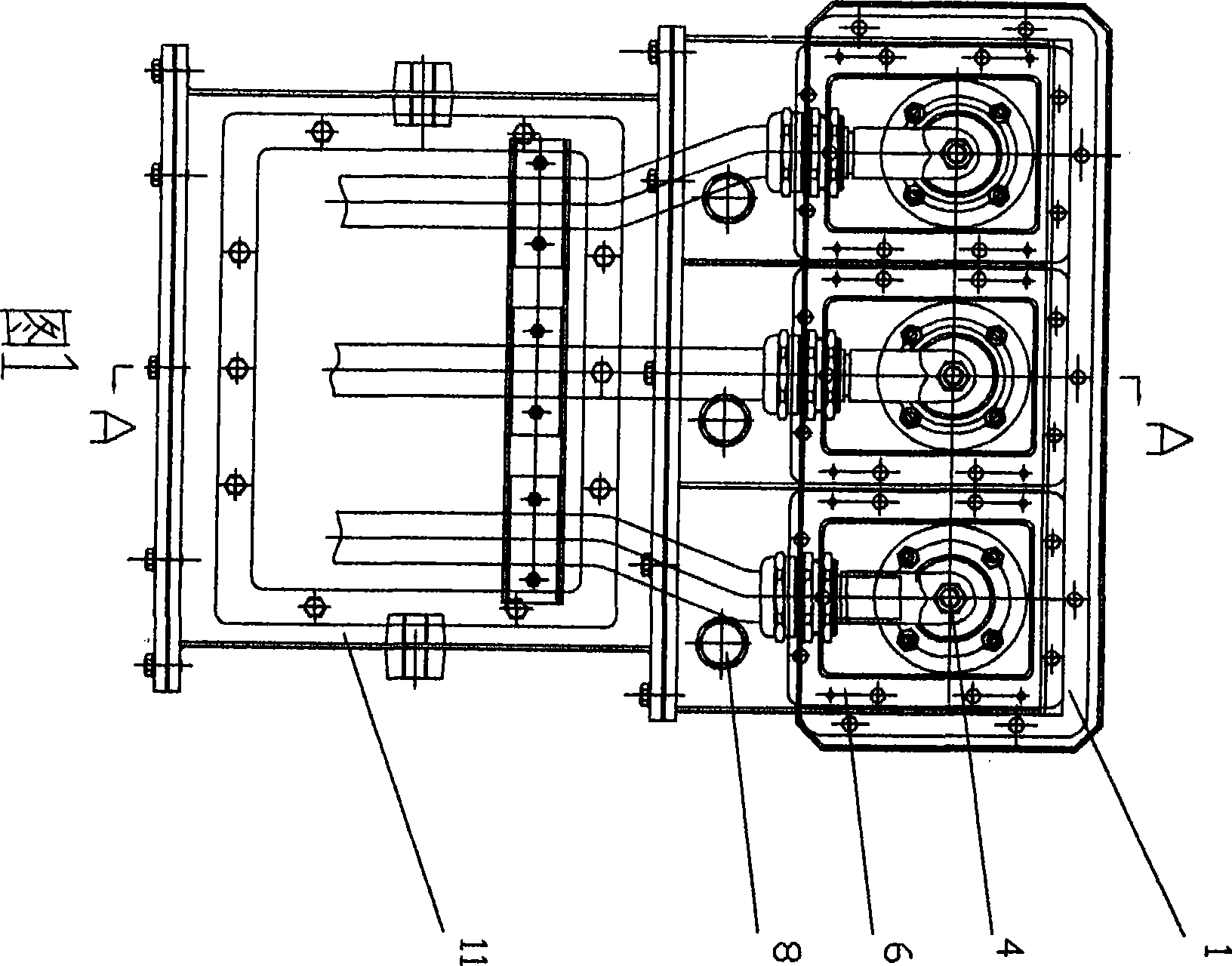

[0009] As shown in the figure, the present invention is composed of a junction box body 1 and a cable sealing box 11 welded by steel plates. There are three mutually closed terminal chambers 2 inside the junction box body 1, and the walls of the terminal chambers are made of epoxy resin material. The junction box body and the rear wall and bottom of the terminal chamber are provided with through holes, the bushing 3 passing through the through hole on the rear wall of the terminal chamber has a sealing bush 5, and the bushing 3 with the conductive rod and the end is connected with the wiring The through hole on the rear wall of the box body 1 is connected to form a conductive channel. The end of the conductive rod passes through the sleeve 3 and is located in the terminal room, and is connected to one end of the external cable 10. The tail end of the conductive rod is larger than the end of the conductive rod and has threads. hole. The cable with copper threaded end led out fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com