Low voltage aluminum electrolysis capacitor formed foil production method

A technology for aluminum electrolytic capacitors and manufacturing methods, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of loss of electrostatic capacity, oxide film thickness, low processing efficiency, etc., achieve high passivation processing efficiency, improve hydration resistance, Effect of High Capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

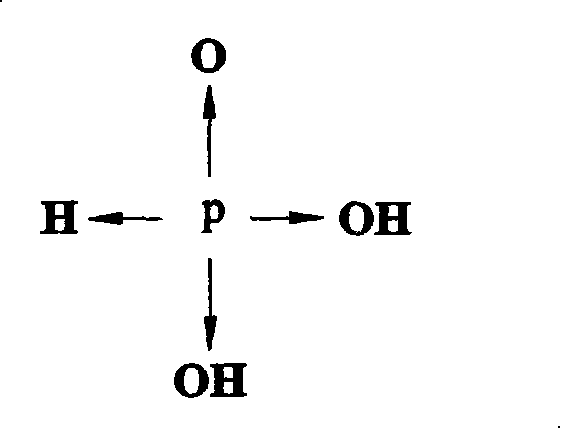

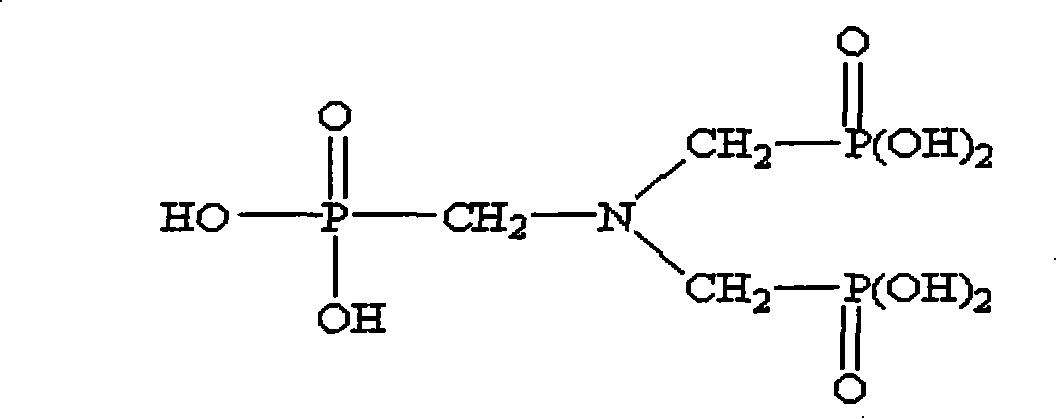

Method used

Image

Examples

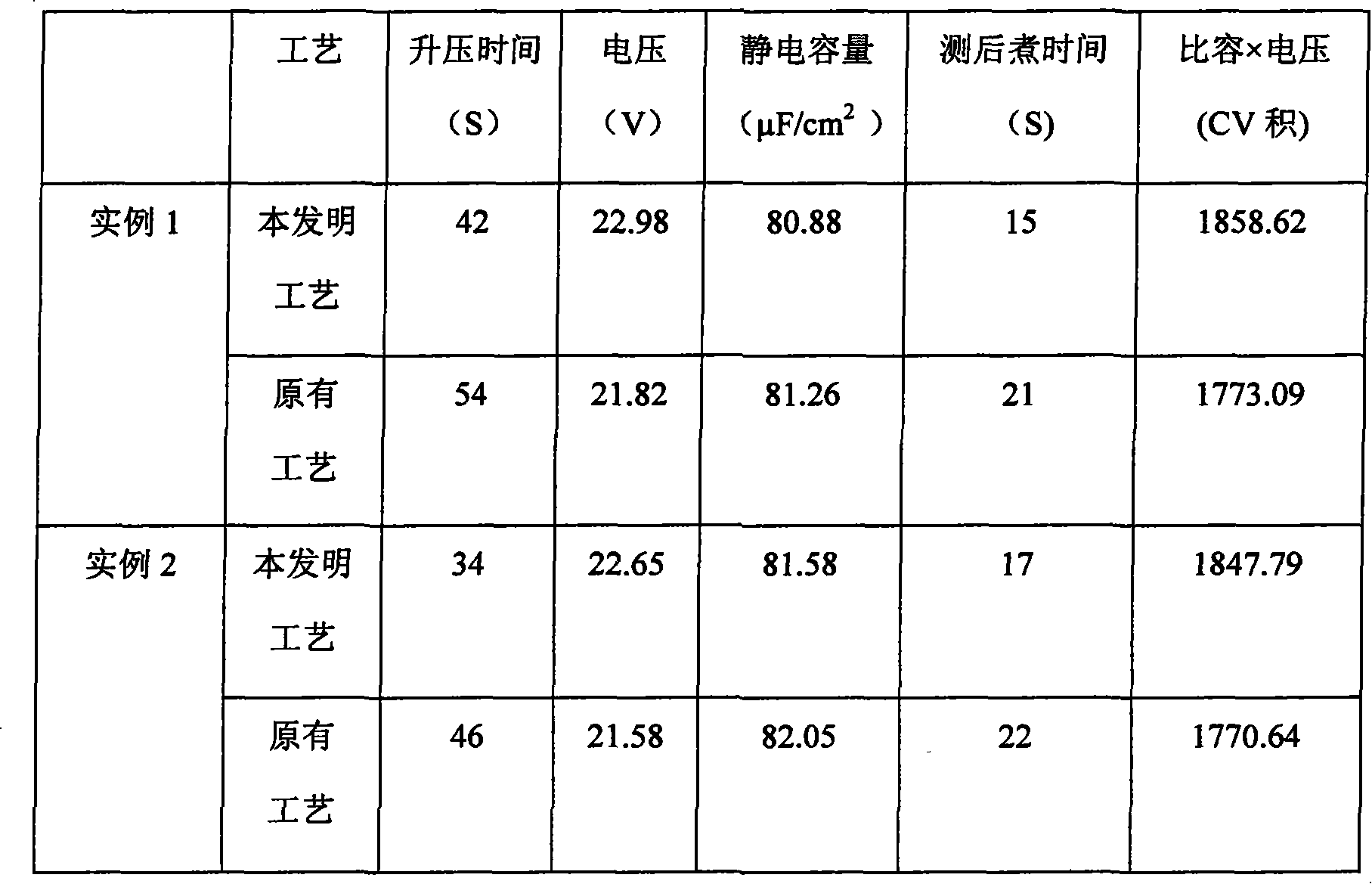

Embodiment 1

[0027] According to the method of the present invention, making the foil with the highest conversion voltage of 20V, the specific method is as follows:

[0028] 1) The low-pressure corroded foil is subjected to chemical conversion treatment in 0.4mol / ammonium adipate solution at 75°C, divided into three stages, and the voltages are respectively first-level: 20V×40%=8V; second-level: 20V×80%=16V ;Third level: 20V×100%=20V, that is, the highest voltage is 20V;

[0029] 2) Soak the foil in 60°C, 0.02mol / L phosphorous acid solution for 2 minutes, and then wash it with pure water;

[0030] 3) Perform chemical conversion treatment on the foil again in the bath solution of 1), and the chemical conversion voltage is 20V;

[0031] 4) Clean the formed foil and heat-treat it in an air atmosphere at a temperature of 500°C for 2 minutes;

[0032] 5) The foil is chemically treated again, and the forming voltage is 20V; the solution used is 75°C, 0.4mol / L ammonium adipate and 1.5×10 -5 mo...

Embodiment 2

[0045] According to the method of the present invention, it is 20V foil that the highest conversion voltage is made, and the specific method is as follows:

[0046] 1) The low-pressure corrosion foil is subjected to chemical conversion treatment in 0.4mol / L ammonium adipate solution at 75°C, divided into two stages, and the voltages are respectively first stage: 20V×50%=10V; second stage: 20×100%= 20V is the highest conversion voltage of 20V;

[0047] 2) Soak the foil in 60°C, 0.02mol / L phosphorous acid solution for 2 minutes, and then wash it with pure water;

[0048] 3) Perform chemical conversion treatment on the foil again in the bath solution of 1), and the chemical conversion voltage is 20V;

[0049] 4) Clean the formed foil and heat-treat it in an air atmosphere at a temperature of 500°C for 2 minutes;

[0050] 5) The foil was chemically treated again, the solution used was 75°C, 0.4mol / L ammonium adipate and 1.5×10 -5 mol / L mixed solution of ammonium dihydrogen phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com