Method for making colourful filtering touch control substrate

A color filter and substrate technology, which is applied in the input/output process of optics, nonlinear optics, data processing, etc., can solve the problems of limiting the design space of the color filter substrate 30, and achieves improved touch sensitivity and reduced equivalent Resistance value, the effect of reducing process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to enable those who are familiar with the technical field of the present invention to have a better understanding of the present invention, several preferred embodiments of the present invention are enumerated below, together with the accompanying drawings, to describe in detail the composition and desired effects of the present invention.

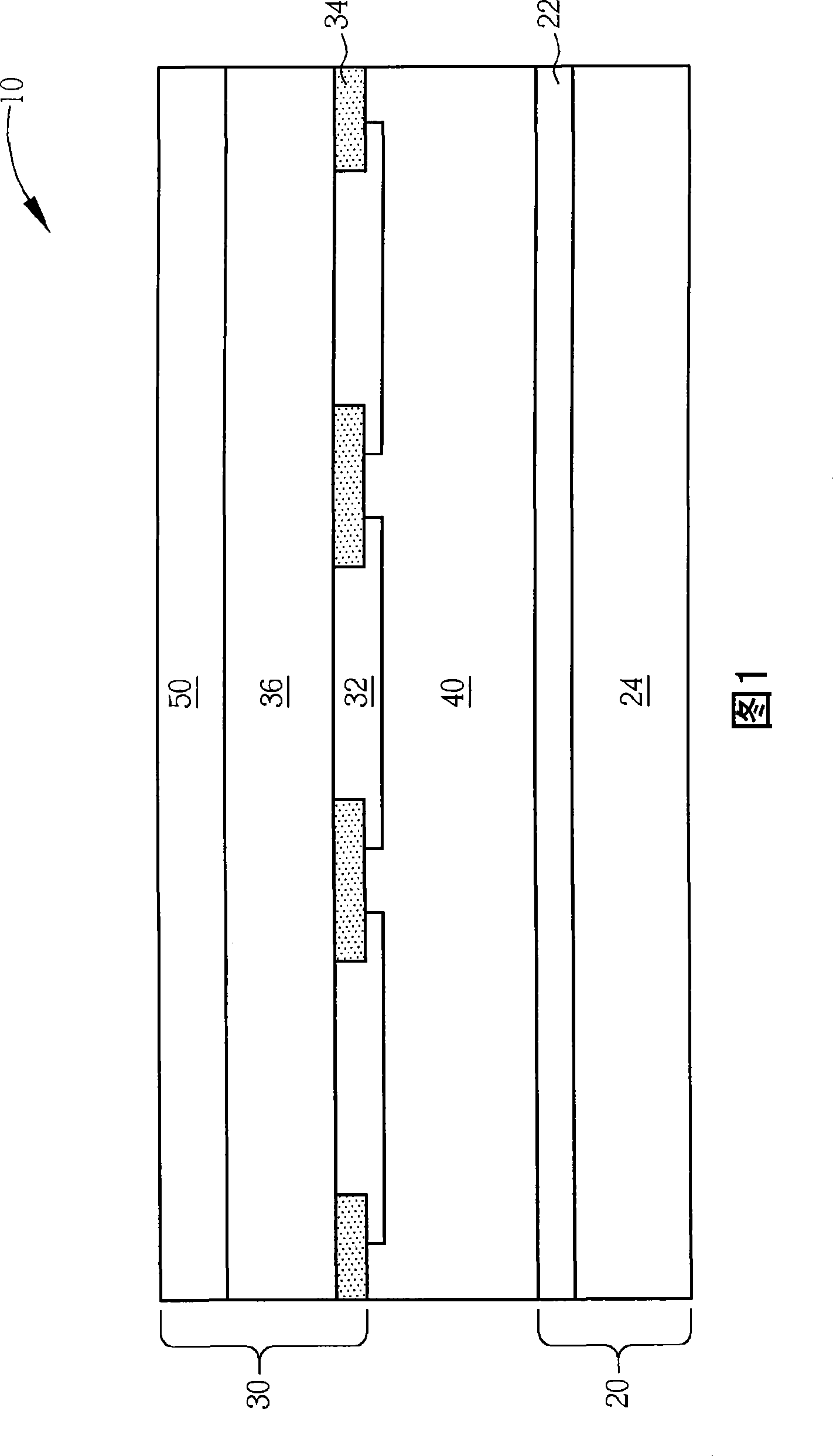

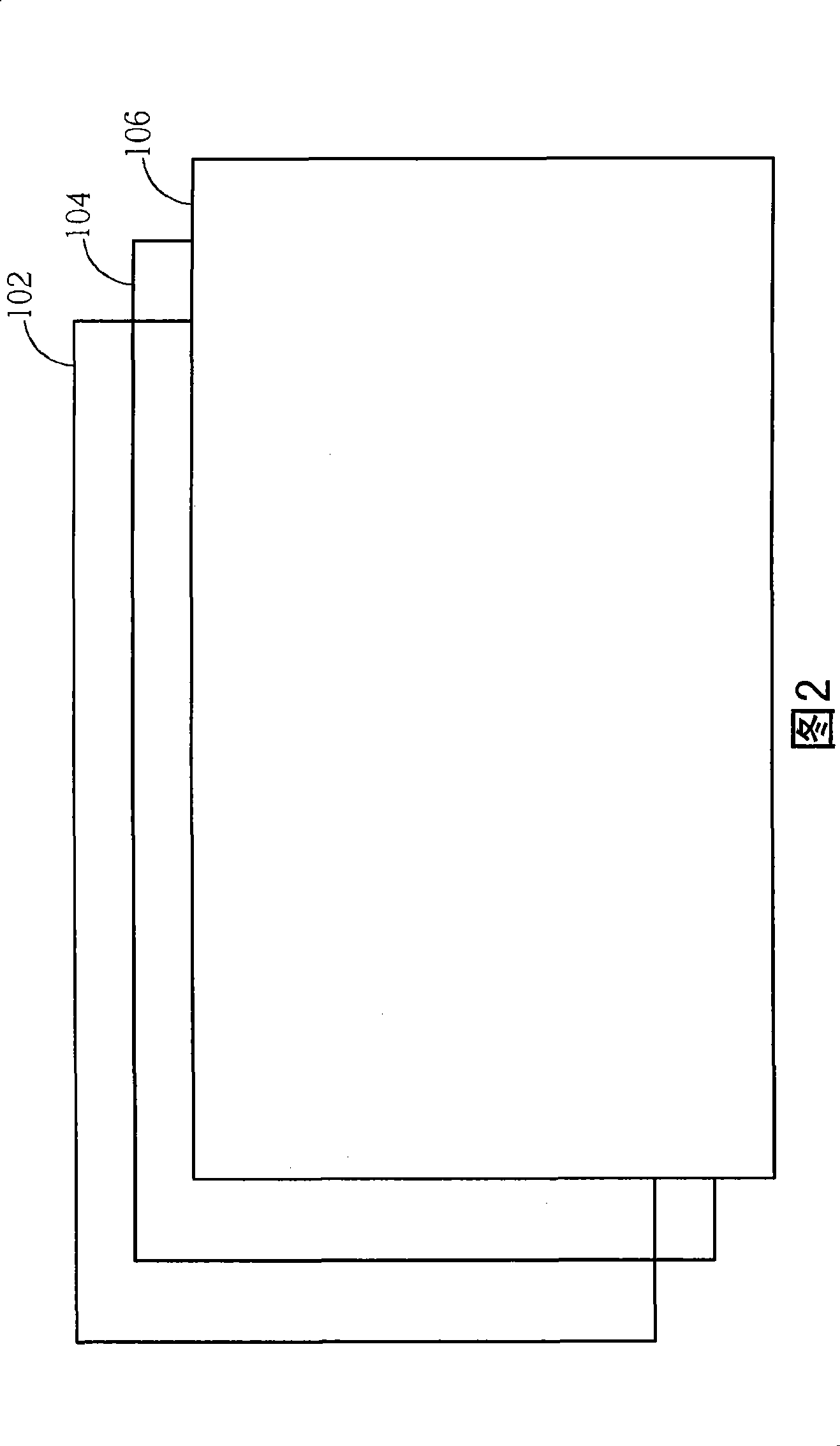

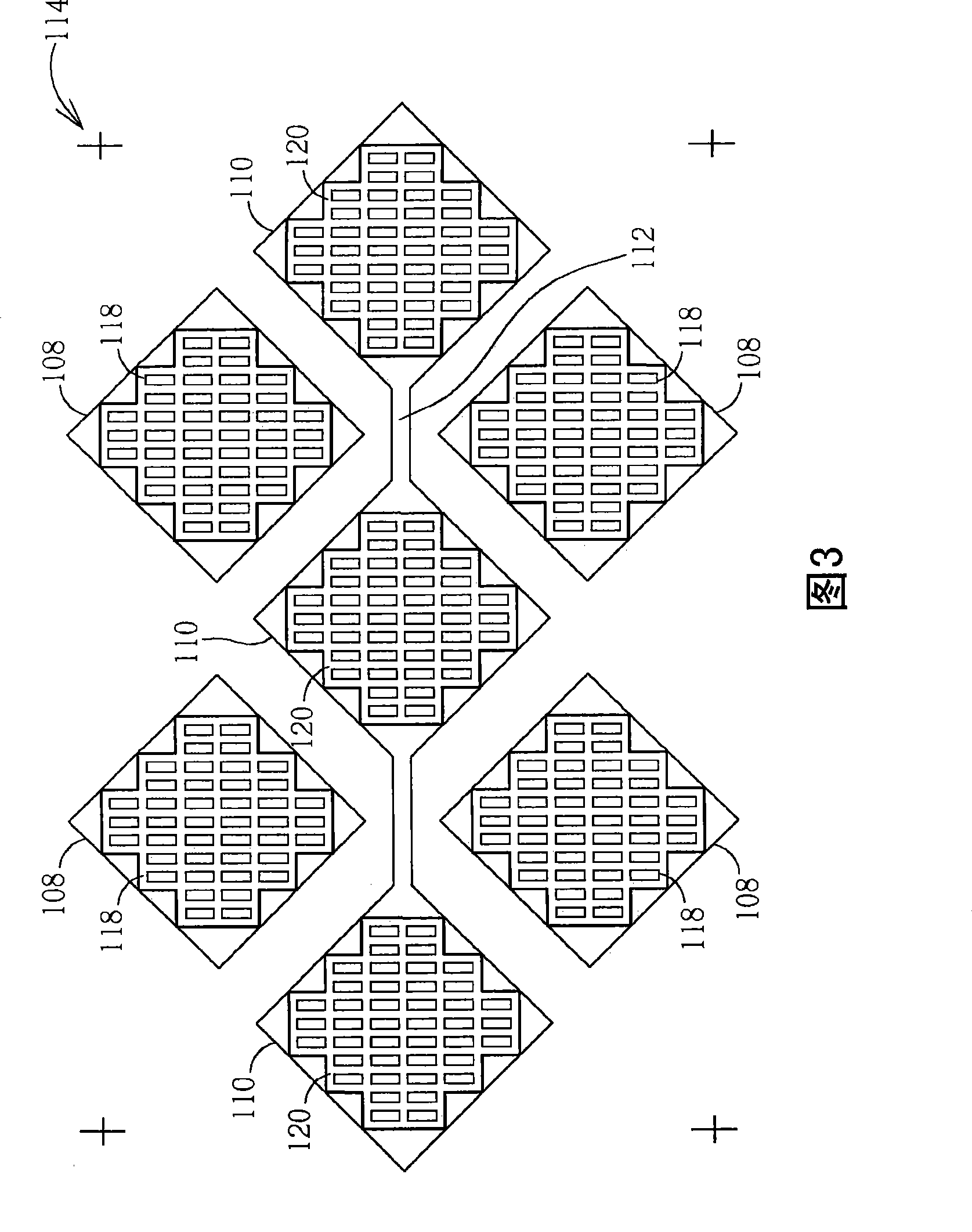

[0053] Please refer to FIG. 2 to FIG. 8, which are schematic diagrams of a first preferred embodiment of the method for manufacturing a color filter touch substrate 100 according to the present invention, wherein FIG. 2 is an exploded schematic diagram of components, and FIGS. 8 is a schematic cross-sectional view of the color filter touch substrate 100 along the section line AA' of FIG. 7 . The same components or parts of the present invention are represented by the same symbols, and the drawings are for illustration purposes only, and are not drawn according to the original scale. As shown in FIG. 2, firstly, a transparen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com