Oblique star wheel single screw compressor

A single-screw compressor, star wheel technology, applied in mechanical equipment, machines/engines, rotary piston machines, etc., can solve problems such as the service life of the star wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

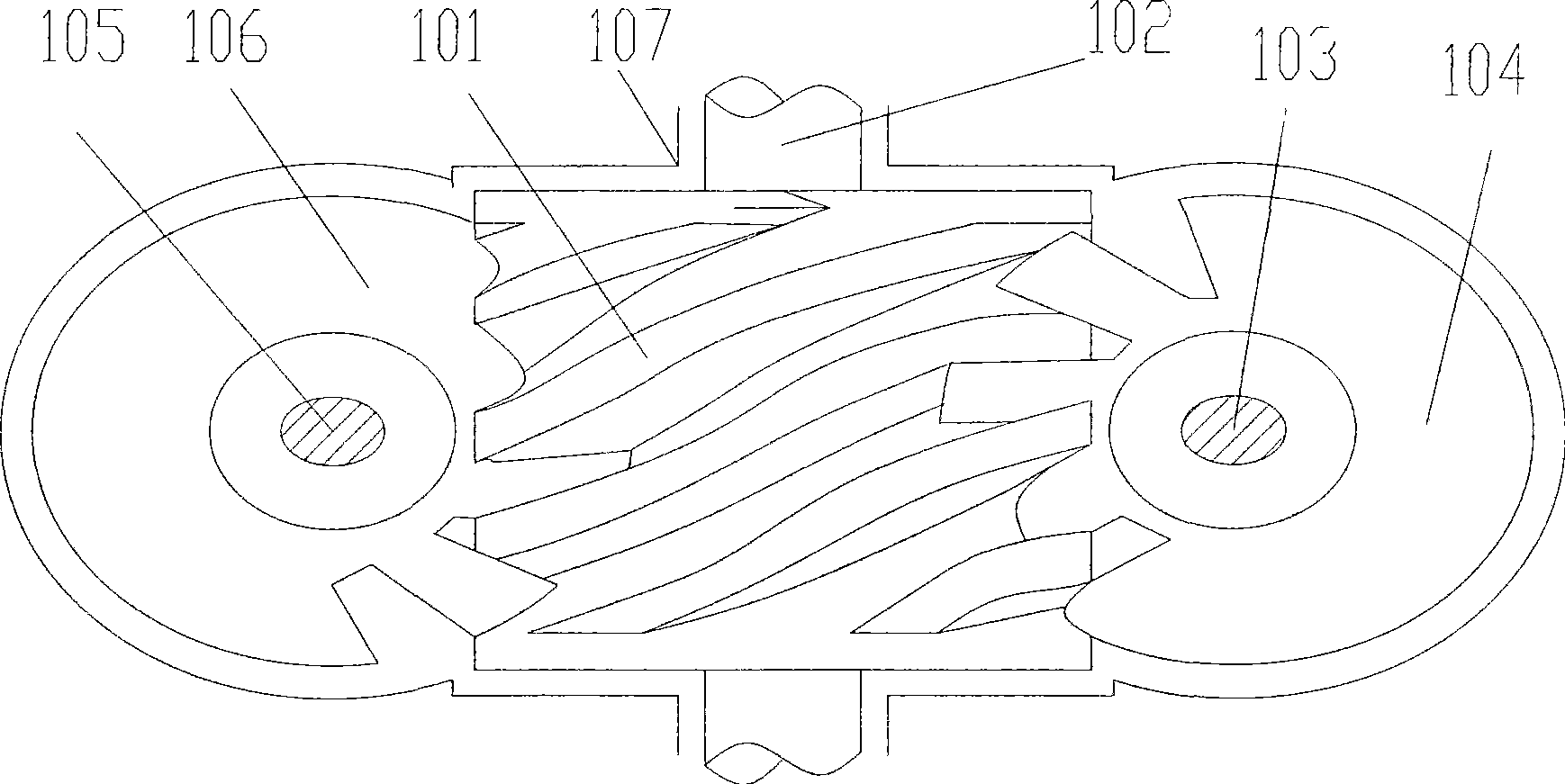

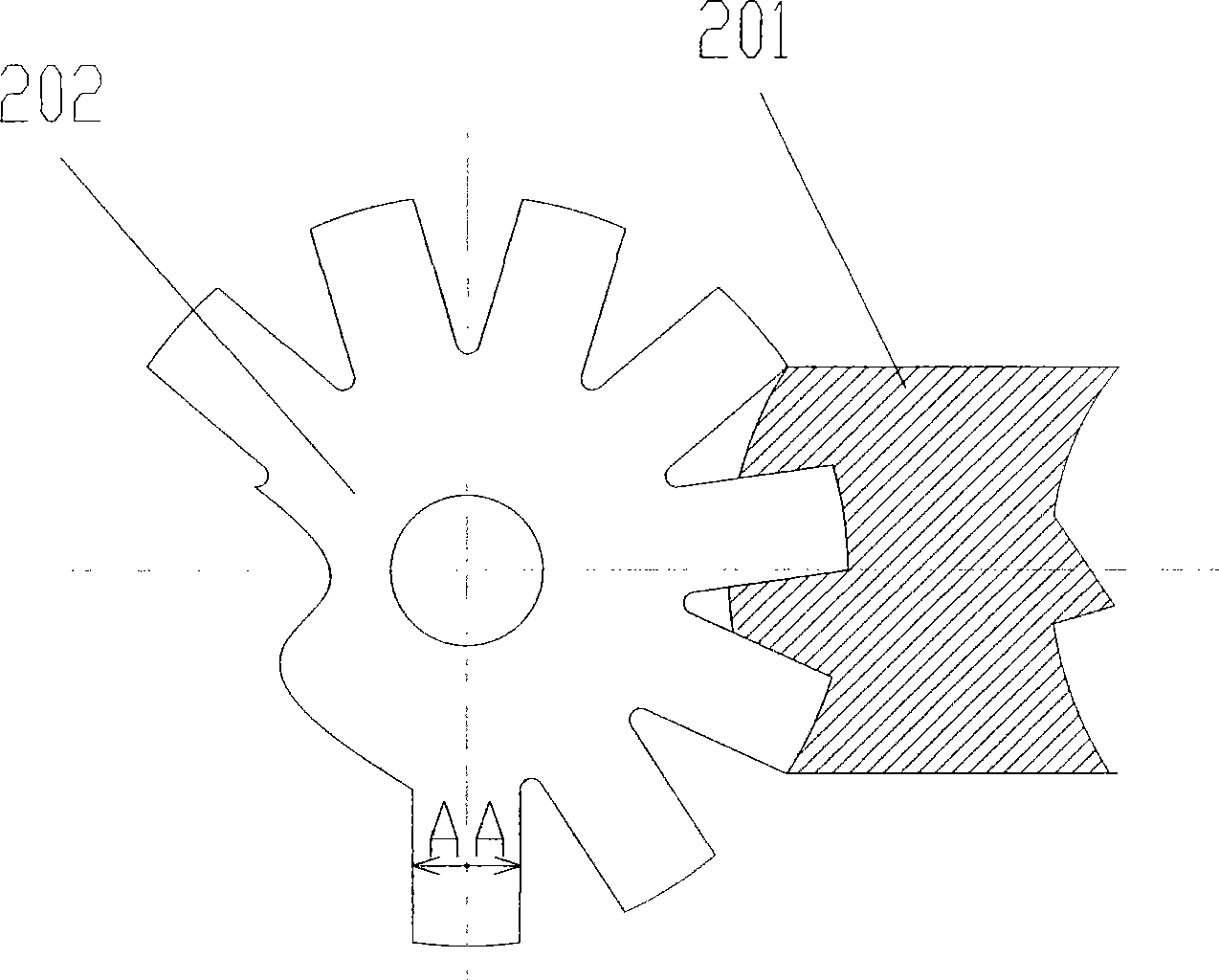

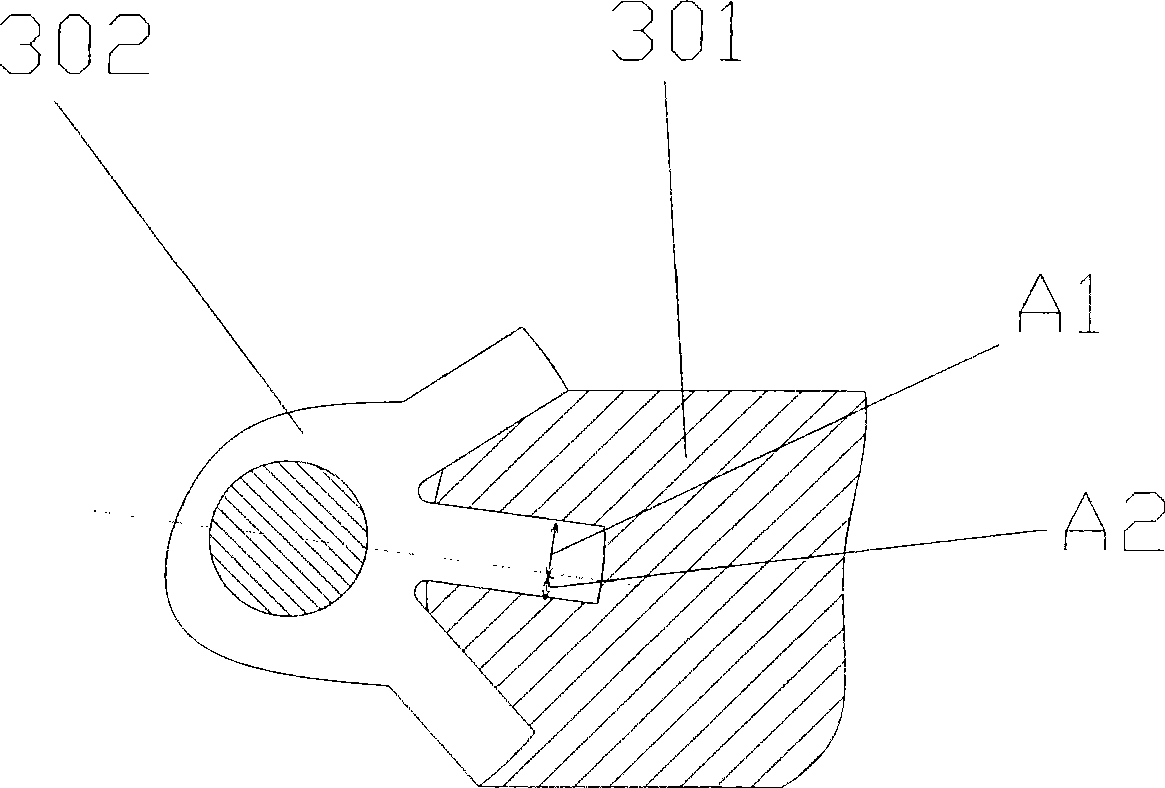

[0008] According to Embodiment 2 of the present invention, the oblique star-wheel single-screw compressor is characterized in that the star wheel engaged with the screw in the single-screw compressor is arranged obliquely, and it includes: a screw and two obliquely engaged screws Equal width star wheel; a body, and the screw shaft and star wheel shaft supported by the body; two star wheels are distributed obliquely on both sides of the screw; between the central axis of the two star wheels and the axis of the screw and between the central axes of the two star wheels The spatial position between them has the characteristic that they are not in the same plane; for single-screw compressors with equal-width teeth as star wheels, the corresponding screw teeth are also equal-width teeth.

[0009] According to Embodiment 3 of the present invention, the single-screw compressor includes a main shaft and a body, and the main shaft frame is supported on a bearing in the body, and is chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com