Method for breeding high sulfurous acid-producing yeast and method for producing liquor using the yeast

A technology of alcoholic beverages and sulfurous acid, applied in the preparation of alcoholic beverages, beer fermentation methods, methods of using fungi, etc., can solve the problems of loss of fermentation characteristics, achieve the effect of inhibiting the generation of peculiar smell and improving the freshness retention period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0143] A DL-ethionine-resistant strain was obtained from the bottom fermentation yeast VTT-A69025 strain for production (obtained from the yeast bank of Kirin Brewery Company) by the following method. Specifically, a single colony of VTT-A69025 grown on a YPD agar medium supplemented with 2% agar was inoculated into 5 mL of a YPD liquid medium, followed by culturing at 20° C. for 3 days. Centrifuge (3000rpm×5 minutes) medium to obtain yeast cell fraction. Add 10 mL of sterile water to the cell part, shake the product well, and then centrifuge the product to obtain the yeast cell fraction again. Repeat this process to wash the yeast cells.

[0144] Suspend the washed yeast cell pellet in 5 mL sterile water. 150 μL of the suspension was coated with 10 mg / mL DL-ethionine, 0.17% Bacto Yeast NitrogenBase w / o Amino Acids and Ammonium Sulfate (Difco), 0.5% ammonium sulfate, 2% glucose, 0.1% lead nitrate and 2 % agar agar medium. Spread 2×10 agar medium in small Petri dishes 6 ye...

Embodiment 2

[0154] A DL-ethionine-resistant strain was obtained from the bottom fermentation yeast KBY011 strain for production by the following method. Specifically, a single colony of KBY011 grown on YPD agar medium supplemented with 2% agar was inoculated into 5 mL of YPD liquid medium, and then cultured at 20° C. for 3 days. Centrifuge (3000rpm×5 minutes) medium to obtain yeast cell fraction. After adding 10 mL of sterilized water to each fraction, it was shaken well and centrifuged again to obtain yeast cell fractions. Repeat this process to wash the yeast cells.

[0155] The obtained (washed) yeast cell pellet was suspended in 5 mL of sterile water, and then coated with 200 μL of the suspension supplemented with 10 mg / mL DL-ethionine, Bacto Yeast Nitrogen Base w / o Amino Acids and Ammonium Sulfate ( Difco), 0.5% ammonium sulfate, 2% glucose, 0.1% lead nitrate and agar medium of 2% agar. Use 2×10 6 Yeast cells were spread on agar medium in small Petri dishes for culture, and then ...

Embodiment 3

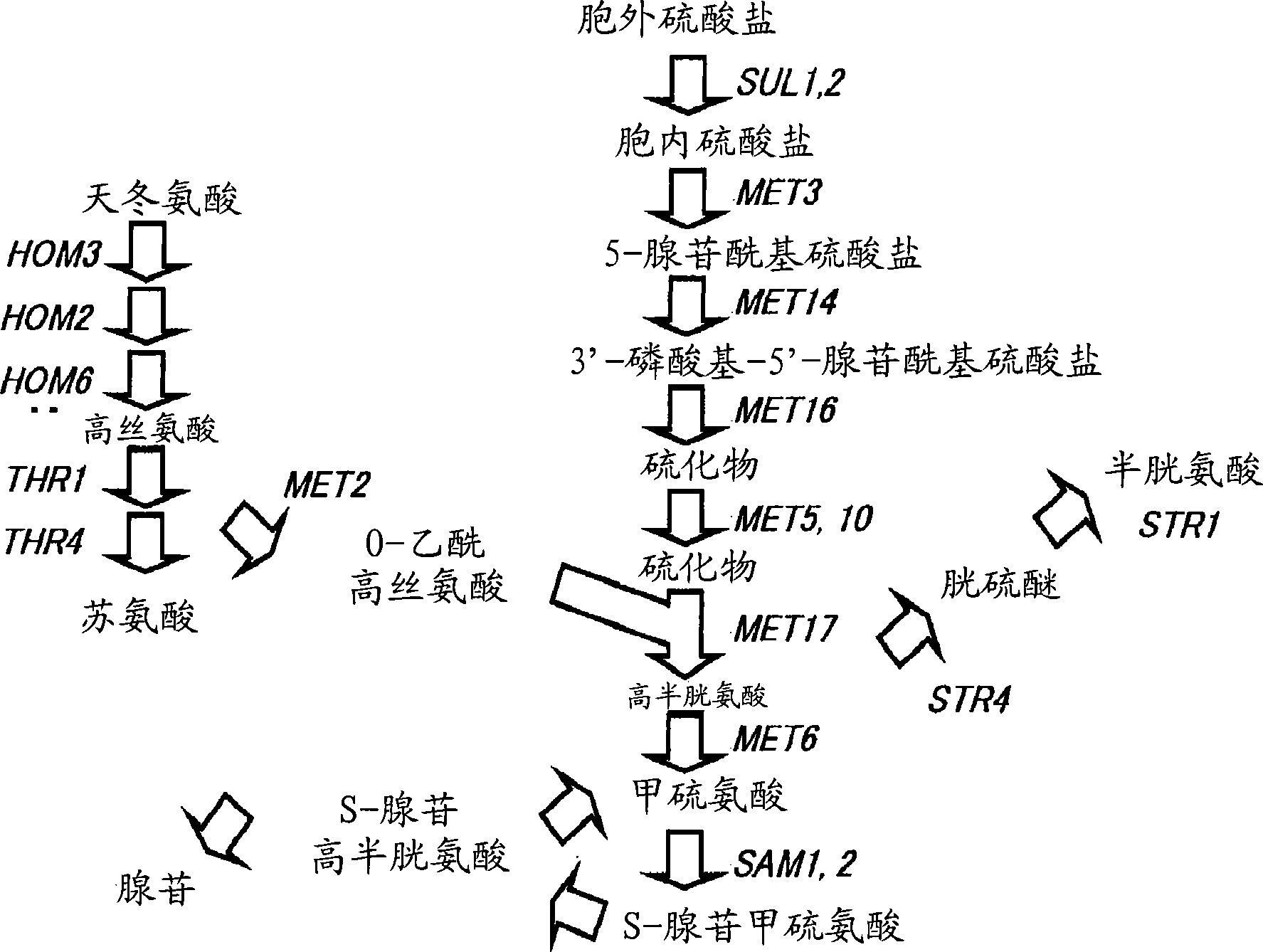

[0163] Subsequently, in order to cultivate compared with the parental strain, due to the increase in the metabolism of hydrogen sulfide from sulfate ion in the metabolic pathway of yeast hydrogen sulfide and sulfurous acid, and the increase in the synthesis of homocysteine from O-acetyl homoserine The amount of metabolism in the acid pathway, and the strain that can increase the production of sulfurous acid without increasing the production of hydrogen sulfide, was tested using the genetic recombination method. The bottom fermentation yeast strain KBY011 for production was sporulated and meiotically divided. Using the isolated meiotic isolate B43, gene recombinants were obtained by the following method. Disruption of the YNL311C gene involved in the stabilization of the Met14 protein to increase the amount of metabolism in the pathway for the synthesis of hydrogen sulfide from sulfate ions. The HOM3 gene was then overexpressed to increase the amount of metabolism in the hom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com