Heat radiating mechanism

A technology of heat dissipation mechanism and heat dissipation main body, which is applied in the direction of cooling/ventilation/heating transformation, semiconductor/solid-state device parts, semiconductor devices, etc., and can solve the problems of heat dissipation and conduction efficiency limitation, small cross-sectional area of conduction and heat conduction, and falling off of heat dissipation mechanism, etc. , to achieve the effect of improving electrical and thermal conductivity, increasing the conductive cross-sectional area, and combining tightly and stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

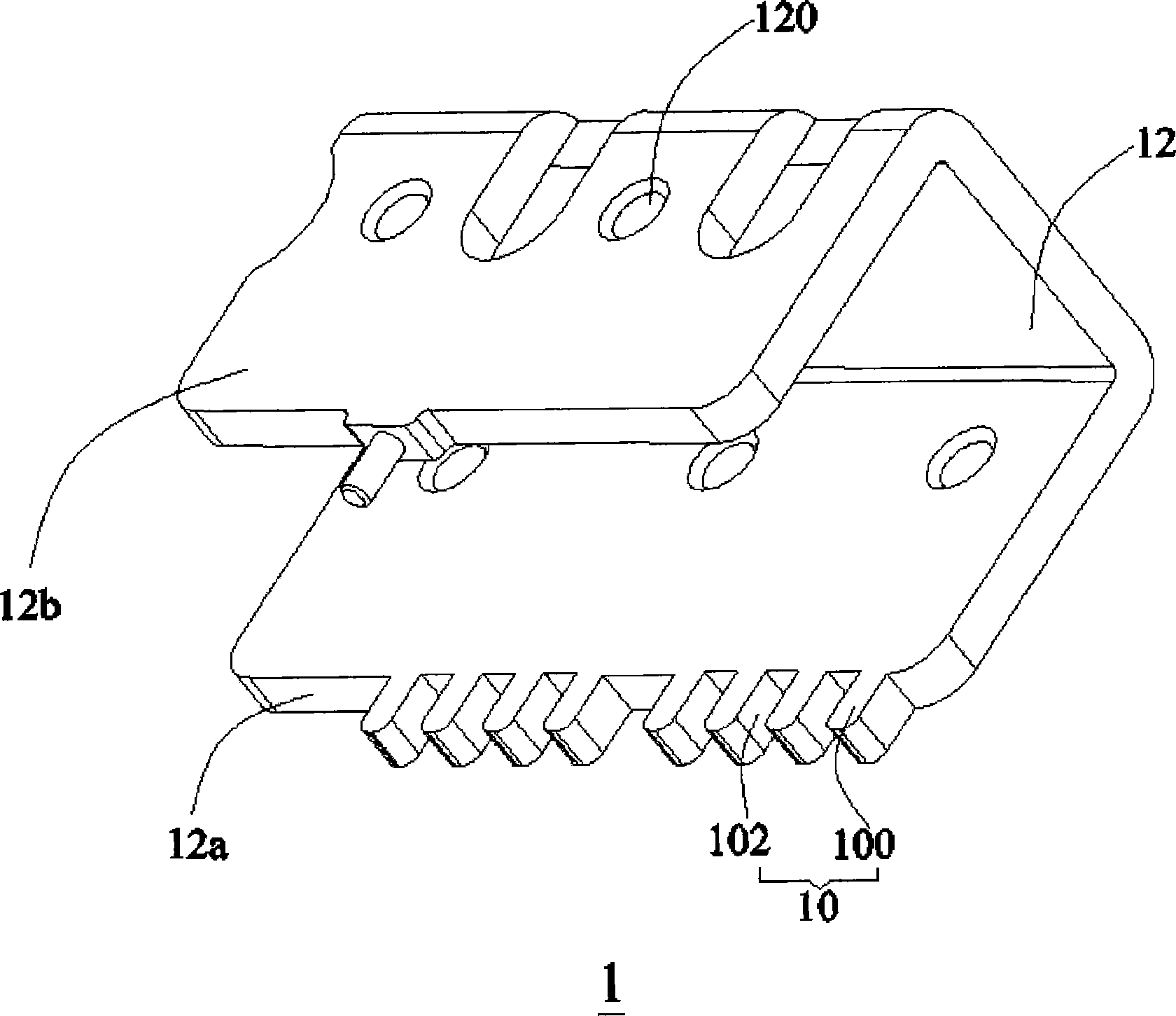

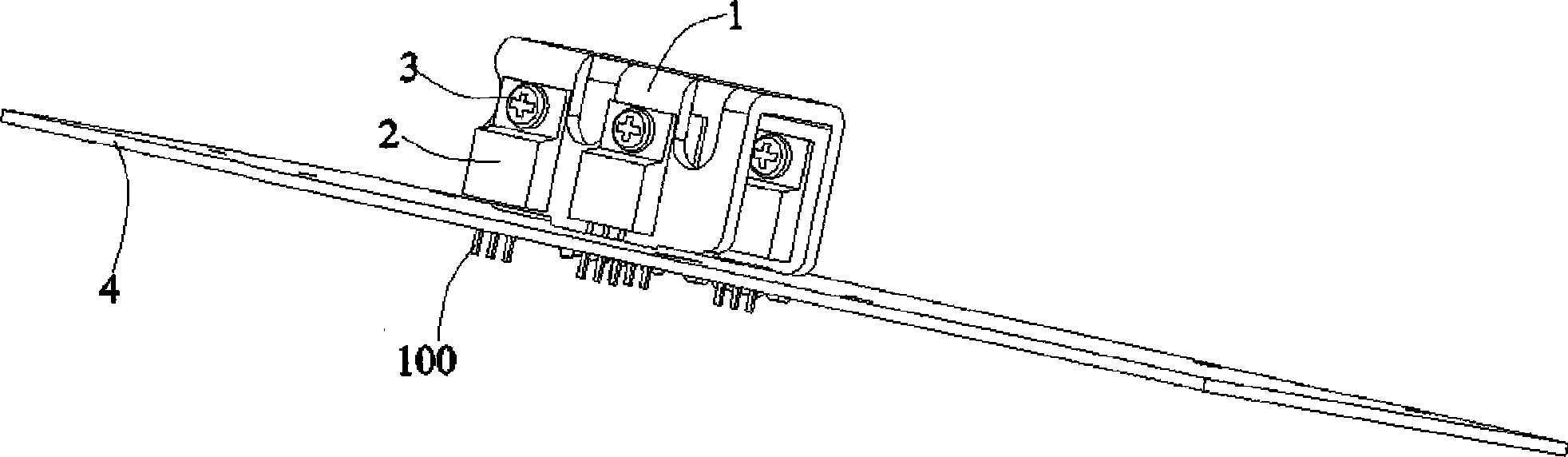

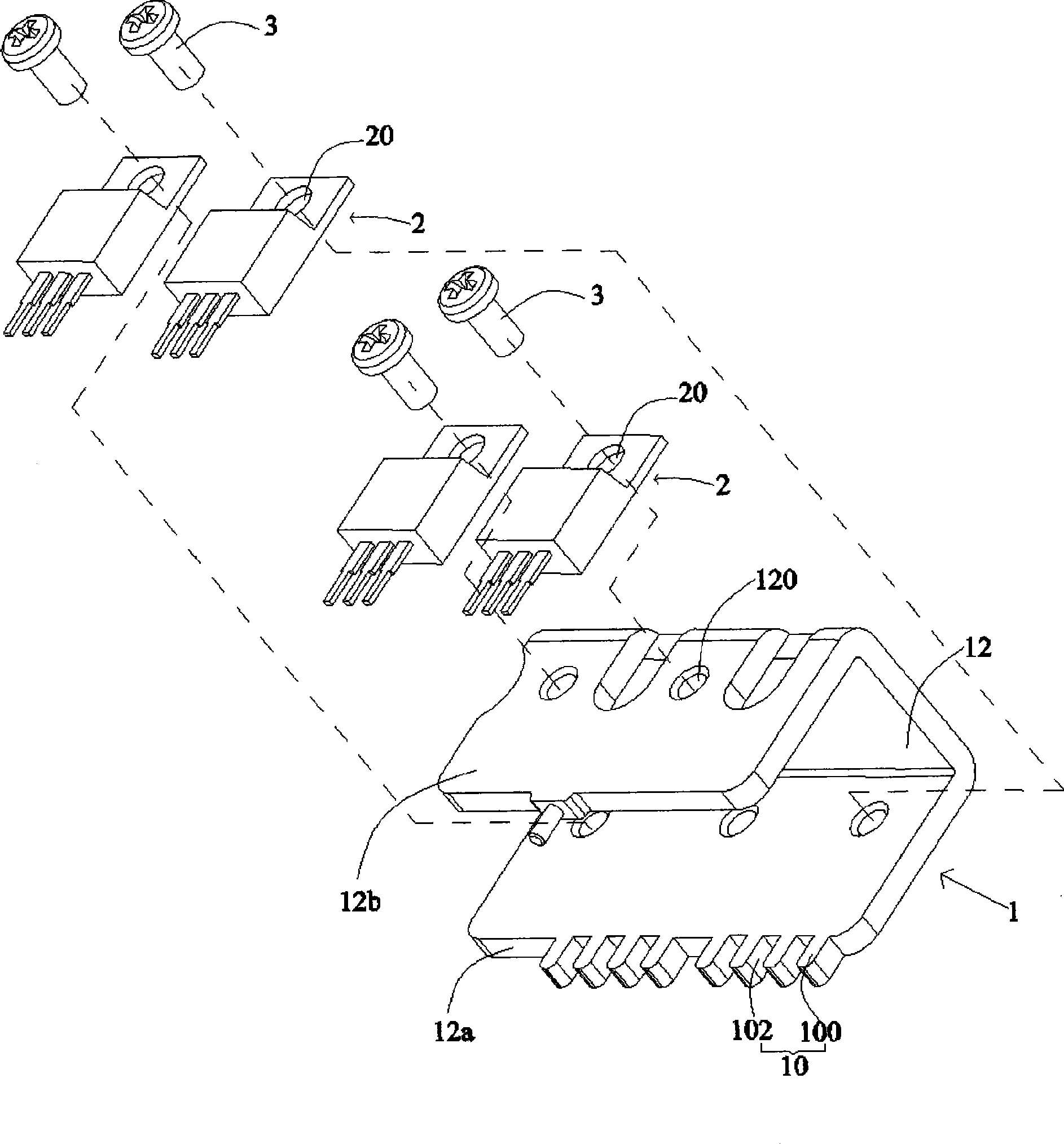

[0015] refer to figure 1 and figure 2 As shown, the present invention provides a heat dissipation mechanism 1, which can be fixed on the printed circuit board 4, and is used to conduct electricity and dissipate heat to the electronic components loaded thereon. The heat dissipation mechanism 1 includes a heat dissipation main body 12 and an extended The connecting portion 10 is provided, wherein the connecting portion 10 has a plurality of pins 100 spaced apart from each other, and the heat dissipation mechanism 1 is electrically connected to the printed circuit board 4 through the pins 100 .

[0016] refer to figure 1 As shown, in one embodiment of the present invention, the heat dissipation mechanism 1 is arched, the heat dissipation body 12 has two end arms 12a and 12b parallel to each other, and the connecting part 10 is extended from the ends of the end arms 12a , the connecting portion 10 includes a plurality of pins 100 spaced apart from each other for electrical conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com