Camera module with automatic focusing function and focusing method thereof

A camera module and driving film technology, which is applied to the focusing device of the camera, the mechanism that generates mechanical power, the camera, etc., can solve the problems of slow electrical response speed, lag, unfavorable fast focusing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

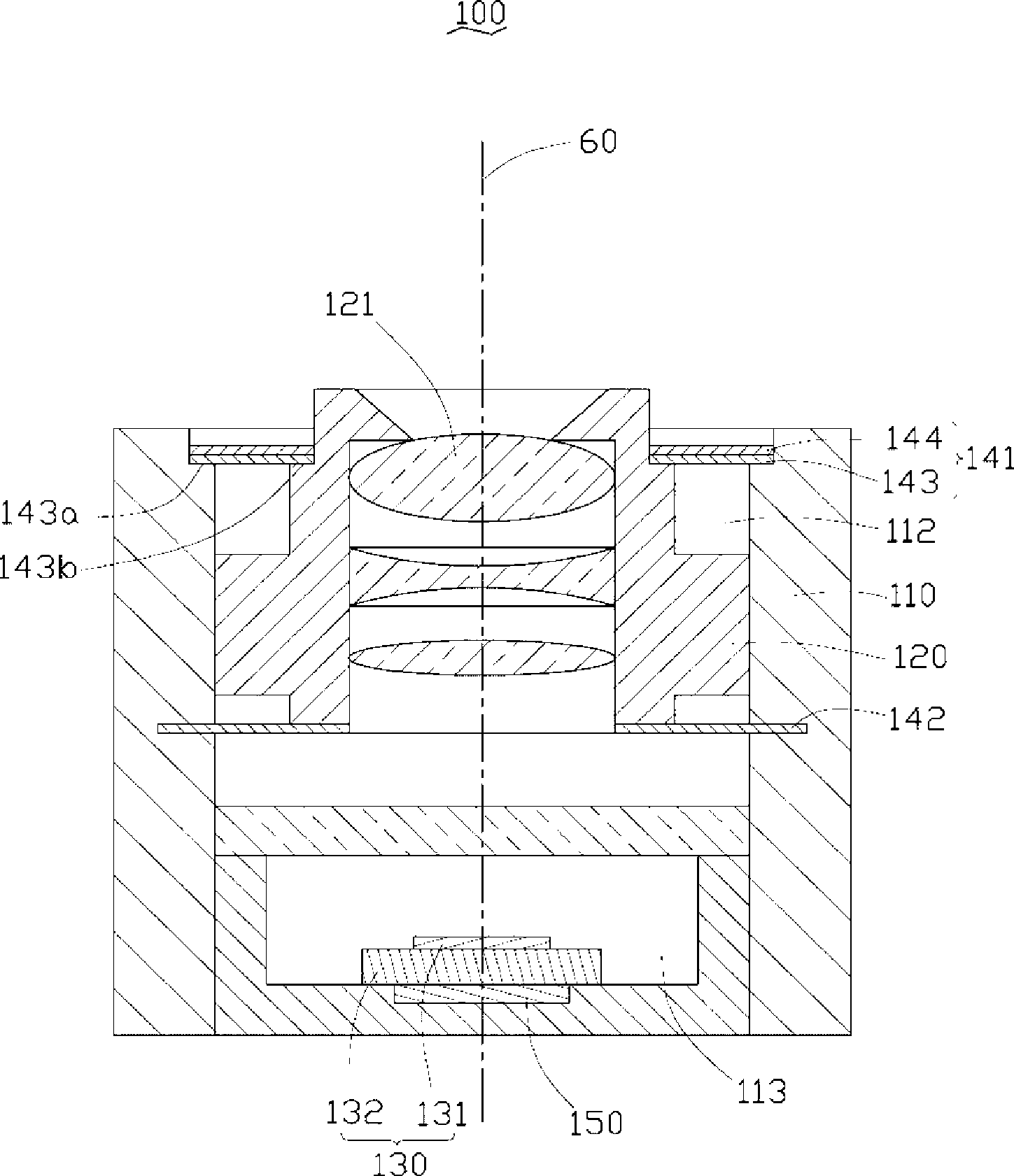

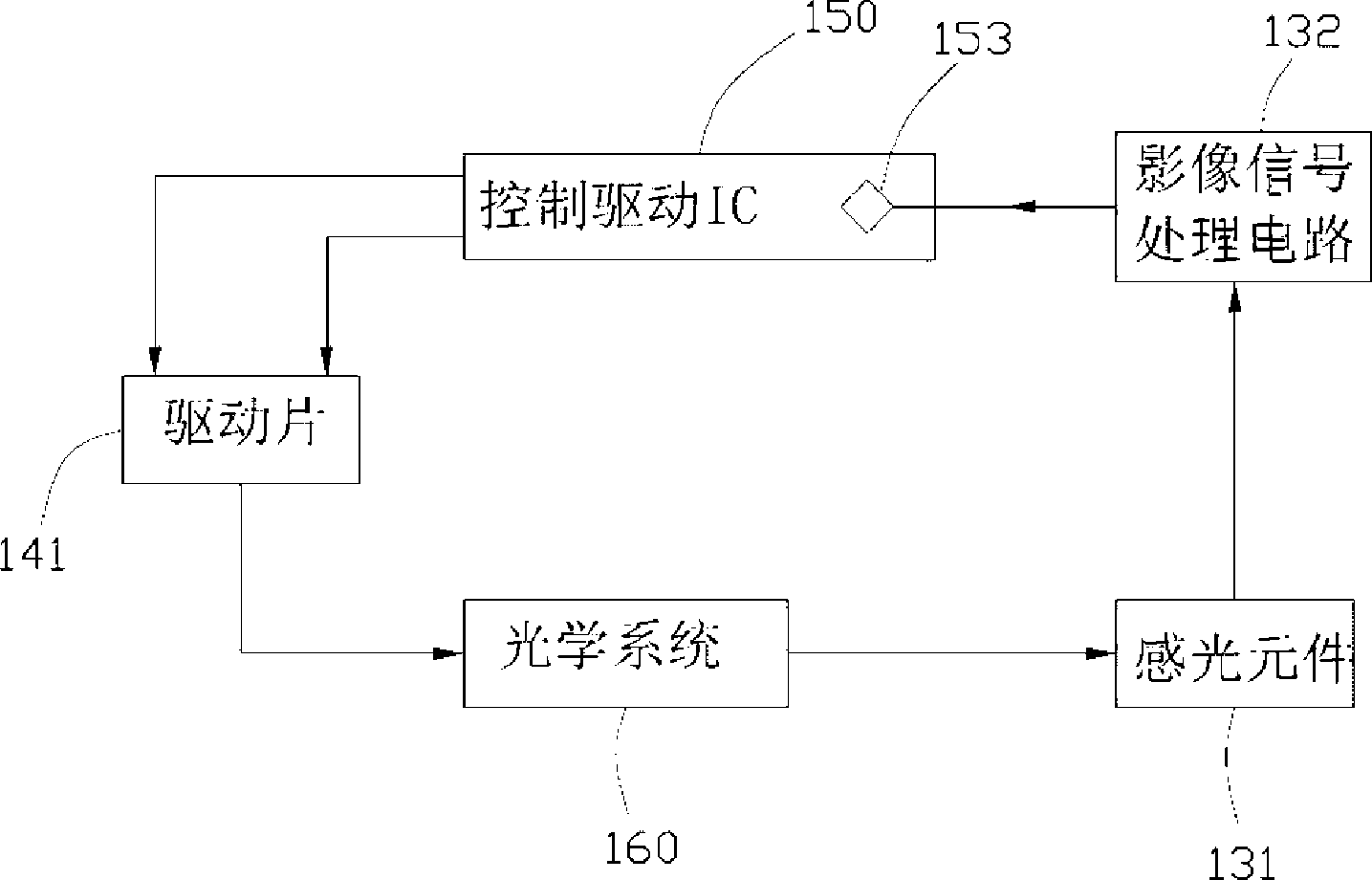

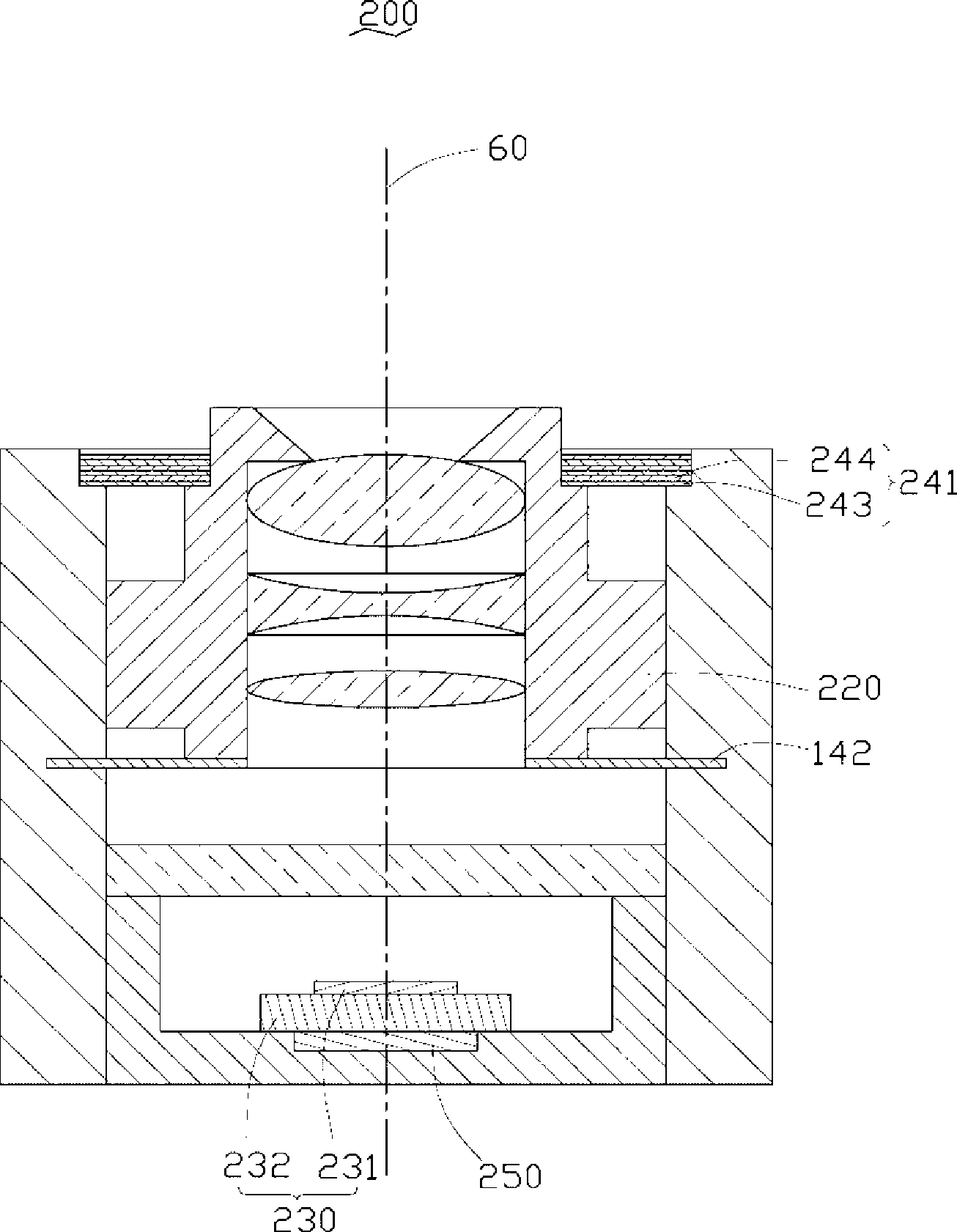

[0028] See figure 1 , Is a camera module 100 provided by the first embodiment of the present invention, which includes a lens holder 110, a lens barrel 120, and an image sensor 130. The lens holder 110 has a top accommodating cavity 112 and a bottom accommodating cavity 113 for accommodating the lens barrel 120 and the image sensor 130, respectively, and the lens barrel 120 is provided with optical elements and image sensors. The device 130 is optically coupled, and the optical center of the lens barrel 120 and the image sensor 130 are located on the same optical axis 60.

[0029] The lens barrel 120 is provided with optical elements, such as various lenses 121 arranged in order. The outer diameter of the lens barrel 120 is equal to the diameter of the top accommodating cavity 112, so that the lens barrel 120 is positioned on the optical axis 60. The direction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com