System and method for measuring and selecting drive gear installation distance adjusting shim of separated main gearbox assembly

A driving gear and main reducer technology, applied in the direction of machine gear/transmission mechanism testing, instruments, measuring devices, etc., can solve problems such as substandard products, low production efficiency, failure, etc., to reduce measurement variation and improve measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

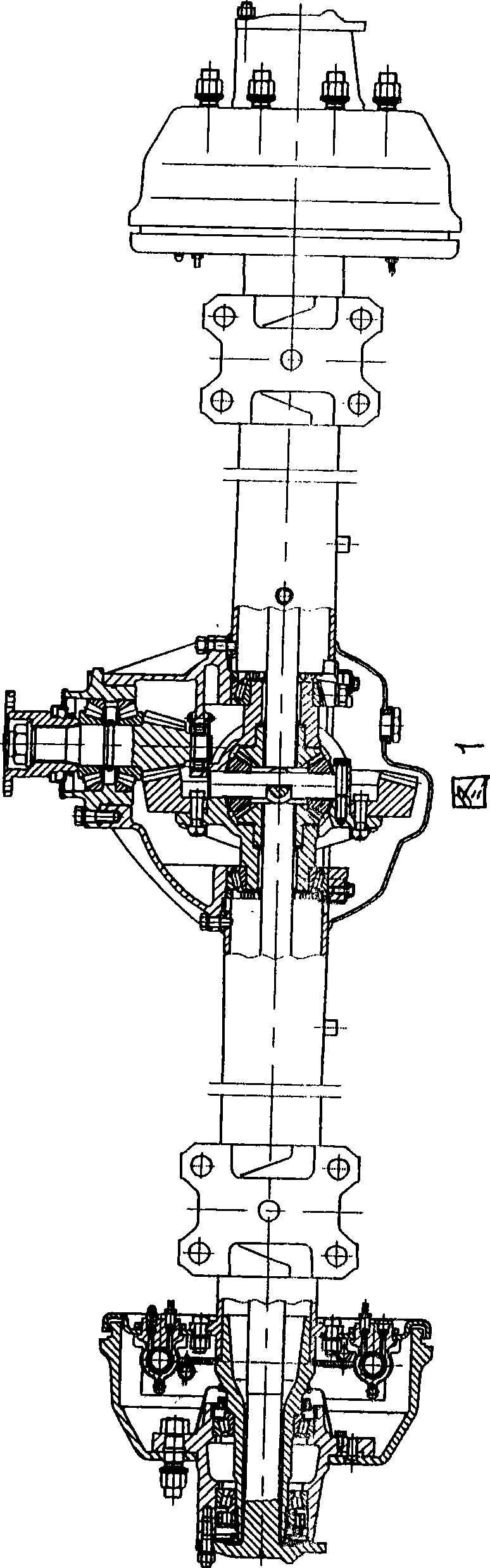

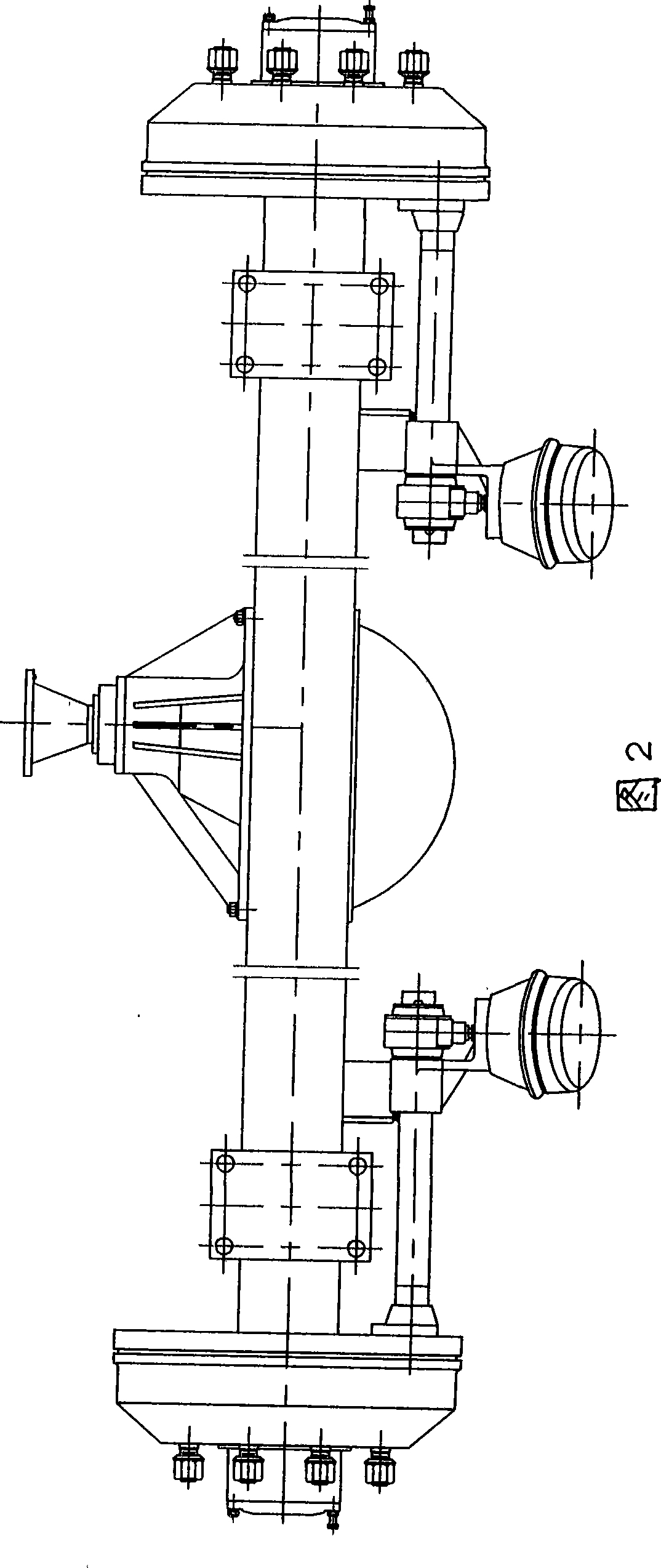

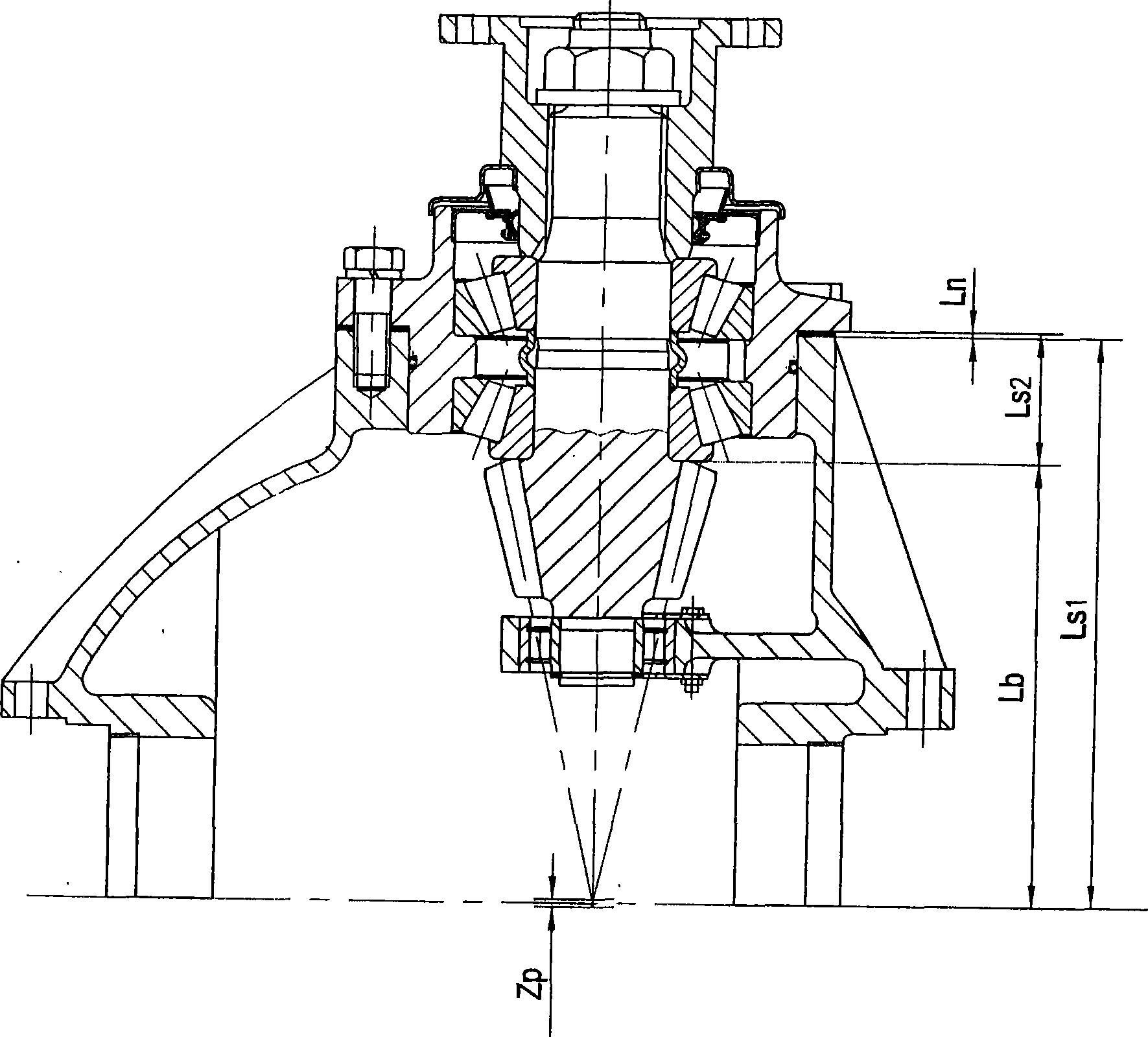

[0022] The driving gear installation distance adjusting gasket measuring and selecting system of the split main reducer assembly mainly consists of the first inspection station, the second inspection station for detecting the driving gear bearing housing subassembly, and the value of the adjusting gasket to be installed. The re-inspection station and electronic control system are composed of the electronic control system, which is composed of the control CPU unit, the axial data signal acquisition channel of the main reducer housing of the two displacement sensors that collect the first detection station, and the first detection station. The guide lifting mechanism execution command output channel, the axial data signal acquisition channel of the bearing seat assembly of the driving gear of the displacement sensor of the second detection station, the vertical pressing mechanism execution command output channel of the second detection station, and the mandrel The output channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com