System for delivering air from a multi-stage compressor to a turbine portion of a gas turbine engine

A gas turbine and compressor technology, applied in the direction of gas turbine devices, mechanical equipment, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

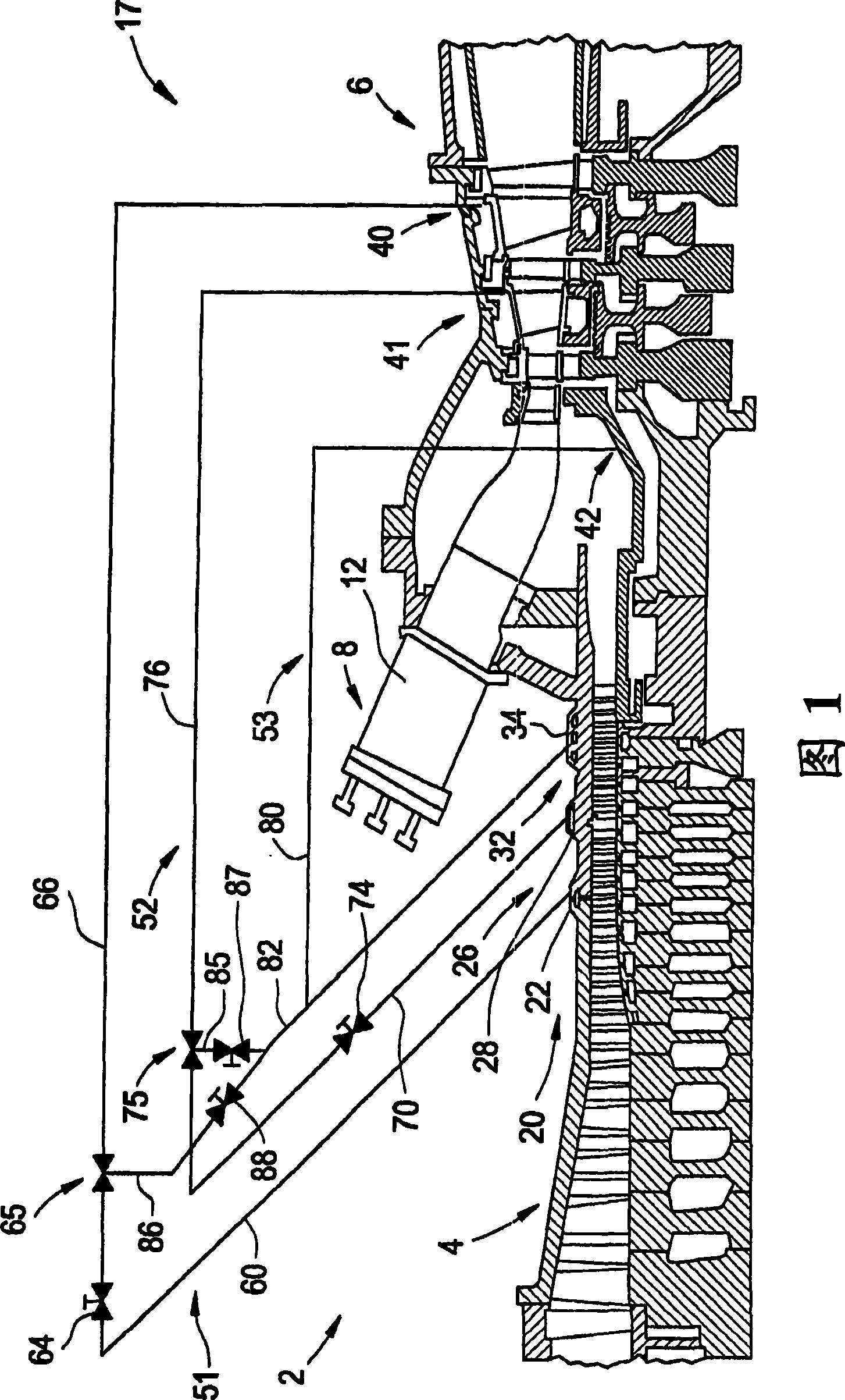

[0043] Referring first to FIG. 1 , there is indicated generally at 2 a gas turbine engine constructed in accordance with an exemplary embodiment of the present invention. Engine 2 includes a compressor 4 operably connected to a turbine 6 via a shaft (not separately labeled). Engine 2 is also shown to include a combustor assembly 8 that includes a combustion chamber 12 . As will be discussed more fully below, combustion gases are generated in combustor assembly 8 and used to drive turbine 6 .

[0044] In operation, air flows into the compressor 4 and is compressed into a high pressure gas. This high pressure gas is fed to the burner assembly 8 and mixed with fuel such as process gas and / or synthetic gas (syngas). A fuel / air or combustible mixture is introduced into combustor 12 and ignited to form a high pressure, high temperature combustion gas stream with a temperature of from about 871 degrees Celsius (°C) to 1621°C (1600°F (°F) to 2950°F). Alternatively, combustor assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com