Ore dressing process for desiliconizing bauxite

A bauxite and desiliconization technology, applied in flotation, solid separation and other directions, can solve the problems of difficulty in removing clay sludge, interfering with the flotation process, and difficulty in obtaining washed concentrates with a high alumina-silicon ratio, so as to reduce chemical consumption. , Improve selectivity and ensure the effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Raw material: a mine sample from a certain mining area in Yunnan Bauxite Mine, its main chemical composition is (%)

[0022] Al 2 o 3 SiO 2 Fe 2 o 3 Al-Si Ratio 26.88 8.34 33.79 3.22

[0023] Agent: use one or more of oxidized paraffin wax soap, tall oil, fatty acid and its soaps and derivatives as collectors, use sodium carbonate, sodium hydroxide, metaphosphate, polyphosphate, water One or several of glass and small molecular organic matter are used as regulators for froth flotation.

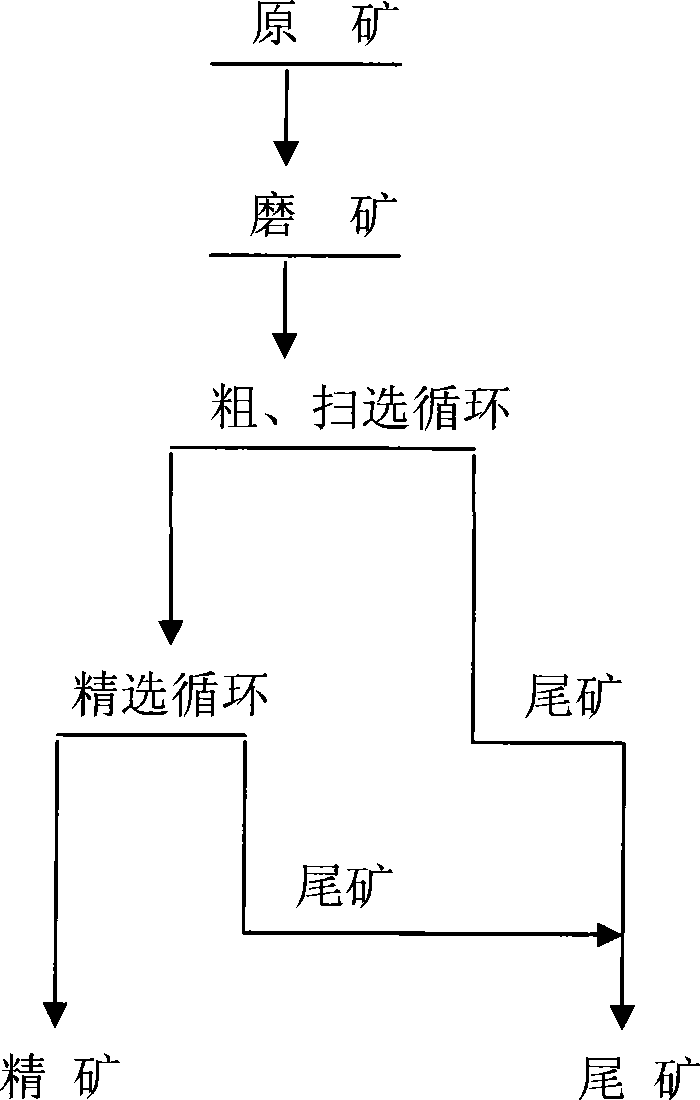

[0024] Specific process flow:

[0025] A. Grind all the ores until the fineness reaches -0.074mm, accounting for 85%, and then enter the rough flotation. The rough flotation adopts the second flotation. Enter the fine flotation process;

[0026] B. Fine flotation adopts secondary selection. The flotation concentrate produced by the two selections is the final concentrate. The scavenging tailings and the tailings in step A are merged into the final t...

Embodiment 2

[0029] Raw material: a mine sample from a certain mining area in Yunnan Bauxite Mine, its main chemical composition is (%)

[0030] Al 2 o 3 SiO 2 Fe 2 o 3 Al-Si Ratio 46.36 18.53 16.65 2.50

[0031] Medicament: with embodiment 1.

[0032] Specific process flow:

[0033] A. Grind all the ores until the fineness reaches -0.074mm, accounting for 80%, and then enter the rough flotation. The rough flotation is one roughing and one sweeping. Selection, the rougher concentrate enters the fine flotation;

[0034] B. Fine flotation is three times of beneficiation. After three times of beneficiation, the output flotation concentrate is used as the final concentrate. After the tailings of the three fine flotation are combined, they are merged with the tailings of step A as the final tailings. .

[0035] Mineral dressing and desiliconization results: concentrate yield 39.79%, aluminum-silicon ratio 11.04, Al 2 o 3 The recovery rate is 52.30%.

Embodiment 3

[0037] Raw material: with embodiment 1.

[0038] Medicament: with embodiment 1.

[0039] Specific process flow:

[0040] A. Grind all the ore until the fineness reaches -0.074mm, accounting for 80%, and then enter the rough flotation. The rough flotation is two roughing and one sweeping. selection, the two roughing concentrates are merged into the beneficiation process;

[0041] B. The beneficiation is twice beneficiation. After two beneficiations, the flotation concentrate is produced as the final concentrate. After the two beneficiation tailings are merged, they are merged with the tailings of step A as the final tailings. .

[0042] Desiliconization results of beneficiation: concentrate yield 61.05%, aluminum-silicon ratio 9.47, Al 2 o 3 The recovery rate is 66.30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com