Traditional Chinese medicine formulation for treating non-insulin dependent diabetes mellitus and preparation method and use thereof

A non-insulin-dependent, diabetic technology, applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems such as toxicity, safety hazards, non-compliance, etc., to achieve toxicity reduction, The effect of lowering triglyceride and cholesterol and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

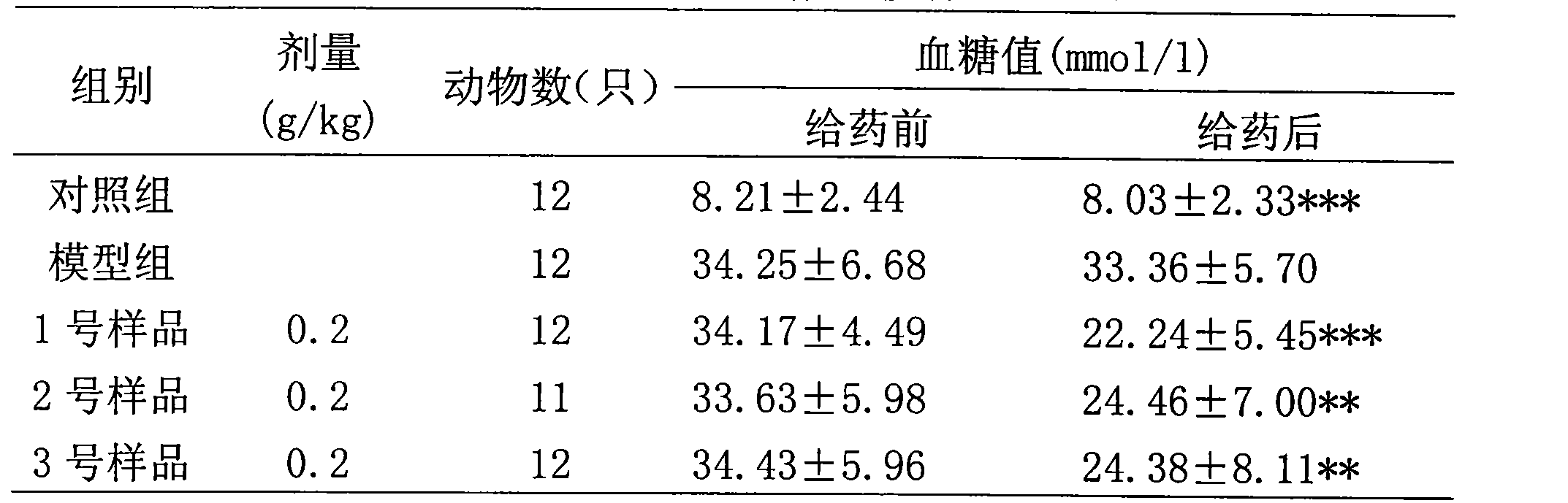

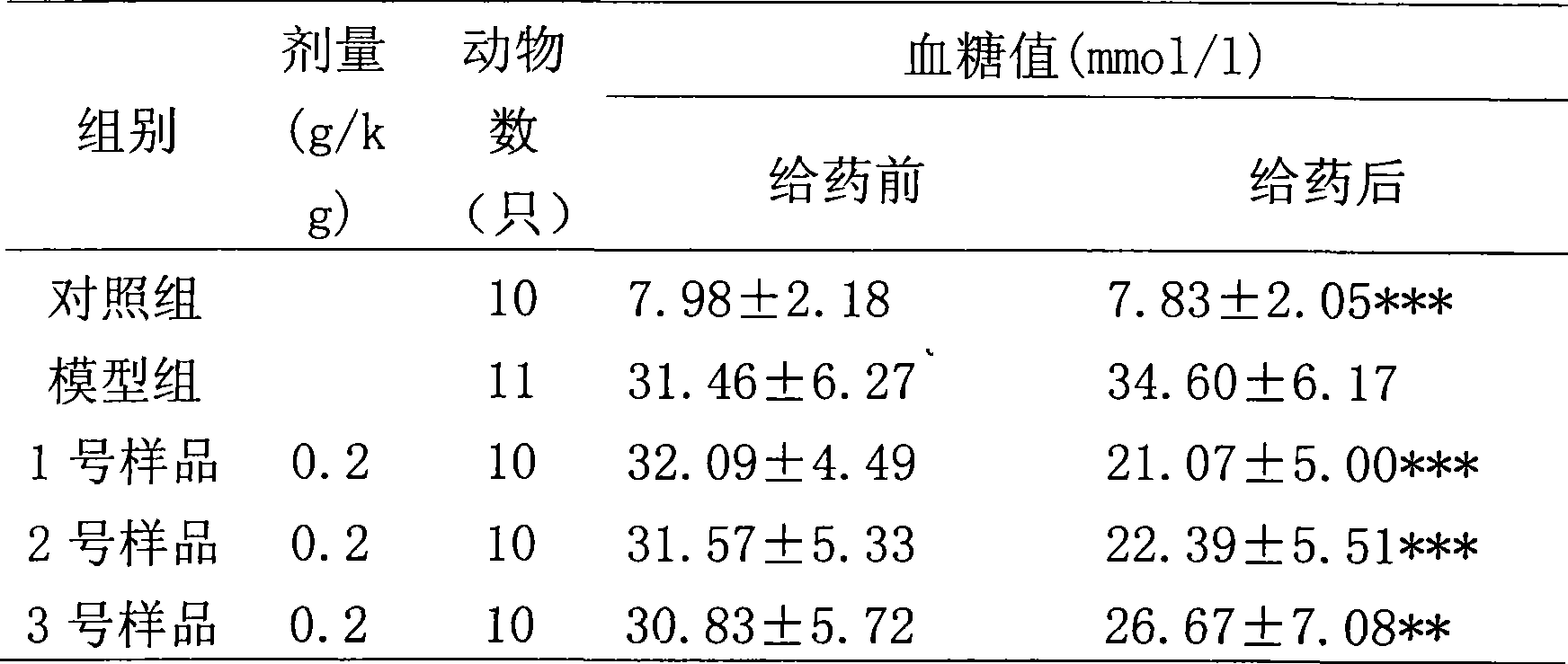

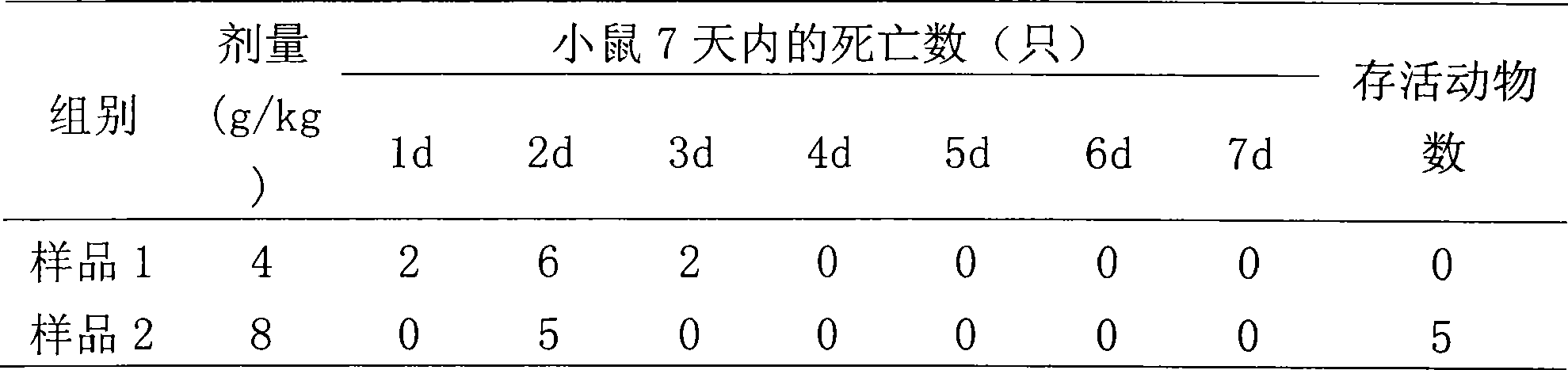

Examples

preparation example Construction

[0022] The preparation method of the traditional Chinese medicine medicament comprises the following steps:

[0023] (1) Weigh the materials according to the percentage by mass of Schisandra chinensis 19-87% and Ligustrum lucidum 13-81%.

[0024] (2) Take Schisandra chinensis, crush it into coarse powder, pass through a 20-40 mesh sieve, and put it in a supercritical extraction tank for extraction. The process conditions are: extraction pressure 21-23Mpa, separation pressure 6-8Mpa, temperature 38-45°C, carbon dioxide flow rate 50-60kg / hr, extraction time about 3-5 hours. A yellow transparent oily extract with a yield of 11-15% was obtained, and its relative density was about 0.98 (measured at 20° C.). After testing, the mass content of volatile oil and lignans fat-soluble substances in the extract is 50-90%.

[0025] (3) Take Ligustrum lucidum, crush it into coarse powder, put it in a multi-functional extraction tank, add 95% ethanol for extraction, 3 to 5 times the amount ...

Embodiment 1

[0033]Weigh Schisandra chinensis 8.5kg and Ligustrum lucidum 1.5kg respectively. Schisandra chinensis is crushed into coarse powder, passed through a 20-40 mesh sieve, and placed in a supercritical extraction tank. The process conditions are: extraction pressure 23Mpa, separation pressure 8Mpa, temperature 44-45°C, carbon dioxide flow rate 50kg / hr, and extraction time about 3 hours. 980 g of a transparent oily extract were obtained with a relative density of 0.98 (measured at 20° C.). After testing, the total content of volatile components and lignans fat-soluble substances in the extract is 51.8%, which is ready for use. Separately take Ligustrum lucidum, crush it into coarse powder, put it in a multi-functional extraction tank, add 4500ml of 95% ethanol to extract, extract twice, each time for 0.5 hours, discard the dregs, combine the two extracts and concentrate under reduced pressure, Obtain 30g of the yellow-brown oily extract, after testing, the content of oleanolic aci...

Embodiment 2

[0035] Weigh Schisandra 2kg and Ligustrum lucidum 8kg respectively. Operation according to embodiment 1, supercritical process condition is: extraction pressure 21Mpa, separation pressure 8Mpa, temperature 43~45 ℃, carbon dioxide flow rate 60kg / hr, extraction time is about 5 hours, obtains the extract of 29g transparent oil, and its relative density is 0.98 (measured at 20°C). After testing, the total content of volatile components and lignans fat-soluble substances in the extract is 52.5%, which is ready for use. The process conditions of Ligustrum lucidum extract are: add 40000ml of 95% ethanol to extract, extract 3 times, each time for 1 hour, discard the dregs, combine the extracts for 3 times and concentrate under reduced pressure to obtain 1440g yellow-brown oily extract. According to the test, the content of oleanolic acid in the extract is 4.5%, and it is ready for use. The content is obtained according to the above extraction method; the viscosity of the capsule mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com