Self-lubricating slide bearing by oil lubrication or grease lubrication

A sliding bearing, grease lubrication technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of pollution, unsatisfactory effect, inconvenient use process, etc., to achieve small wear, excellent friction and wear resistance, friction The effect of small coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

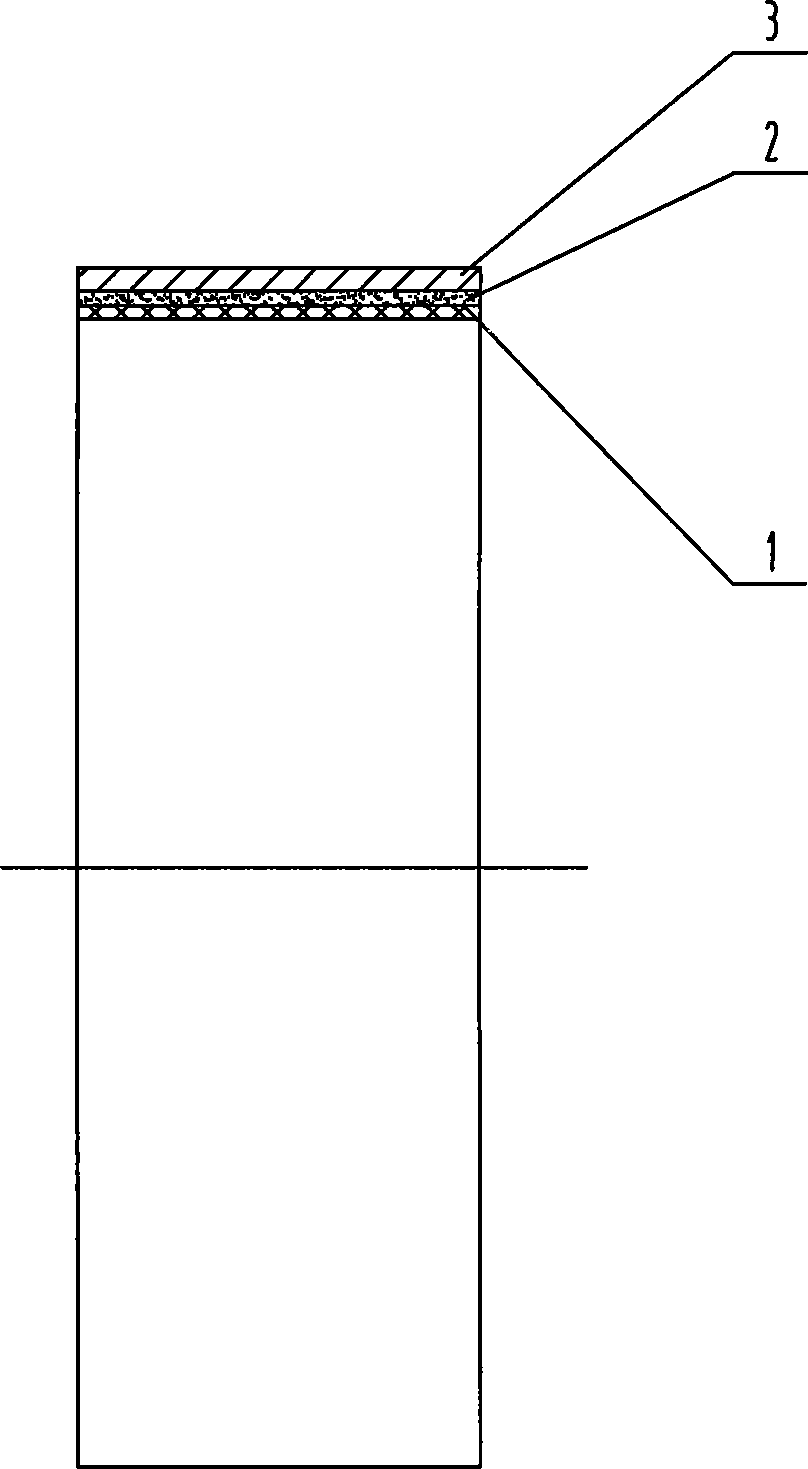

[0031] The present invention is rolled from a three-layer composite material, the three-layer composite material includes a low-carbon steel plate 3, a spherical porous copper powder layer 2 sintered on one side of the steel plate, and a friction-reducing and wear-resistant material layer 1 infiltrated into and covering the copper powder layer , the weight percentage of copper powder layer 2 is composed of: 8% tin powder, 3% zinc powder, and the rest is copper powder; the weight percentage of antifriction and wear-resistant material layer 1 is composed of: 50% polytetrafluoroethylene, 12 % polyether ether ketone, 15% carbon fiber, 5% molybdenum disulfide, 18% tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer (PFA). Its manufacturing method includes the following steps:

[0032] A, sintering the copper powder layer 2 on the low carbon steel plate 3;

[0033] B. Making anti-friction and wear-resistant layer spreadable software

[0034] a, with powder, by weight percent...

Embodiment 2

[0044] The anti-friction and wear-resisting material layer 1 of the present invention is composed by weight percentage: 40% polytetrafluoroethylene, 10% polyether ether ketone, 10% carbon fiber, 3% molybdenum disulfide, 37% tetrafluoroethylene -perfluoroalkoxy vinyl ether copolymer (PFA), all the other material structures and manufacturing methods are the same as in Example 1.

Embodiment 3

[0046] The anti-friction and wear-resisting material layer 1 of the present invention is composed of: 35% polytetrafluoroethylene, 15% polyether ether ketone, 10% carbon fiber, 6% molybdenum disulfide, 34% tetrafluoroethylene -perfluoroalkoxy vinyl ether copolymer (PFA), all the other material structures and manufacturing methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com