Anastomat

A stapler and body technology, applied in the field of staplers, can solve problems such as operation failures and accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

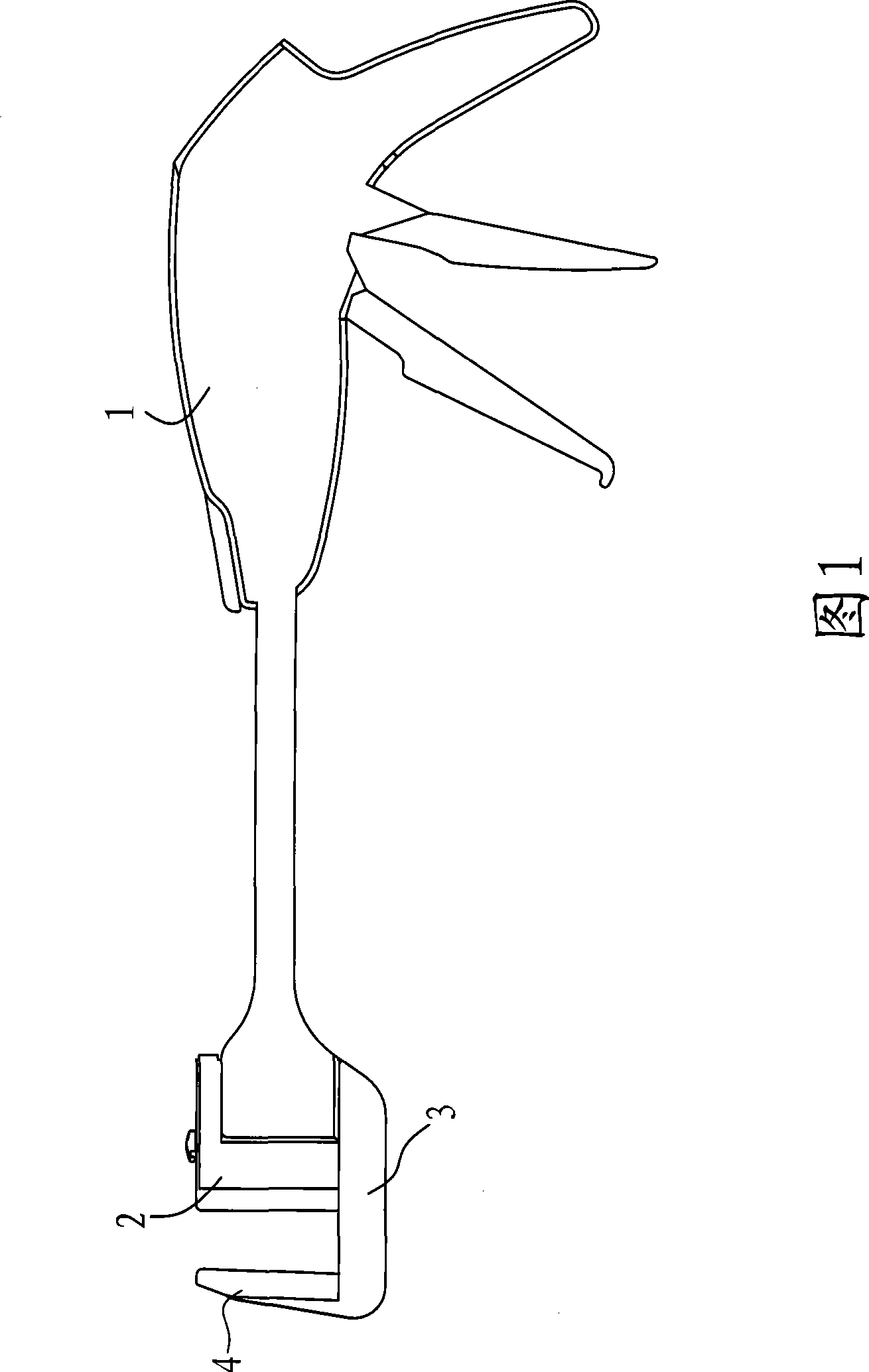

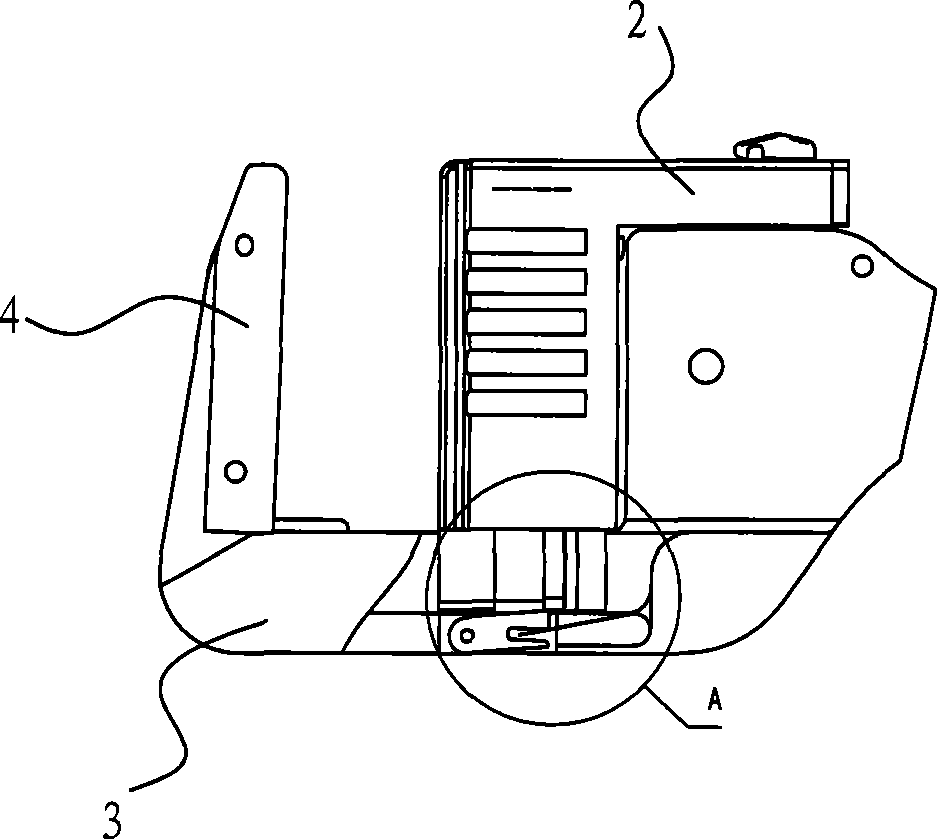

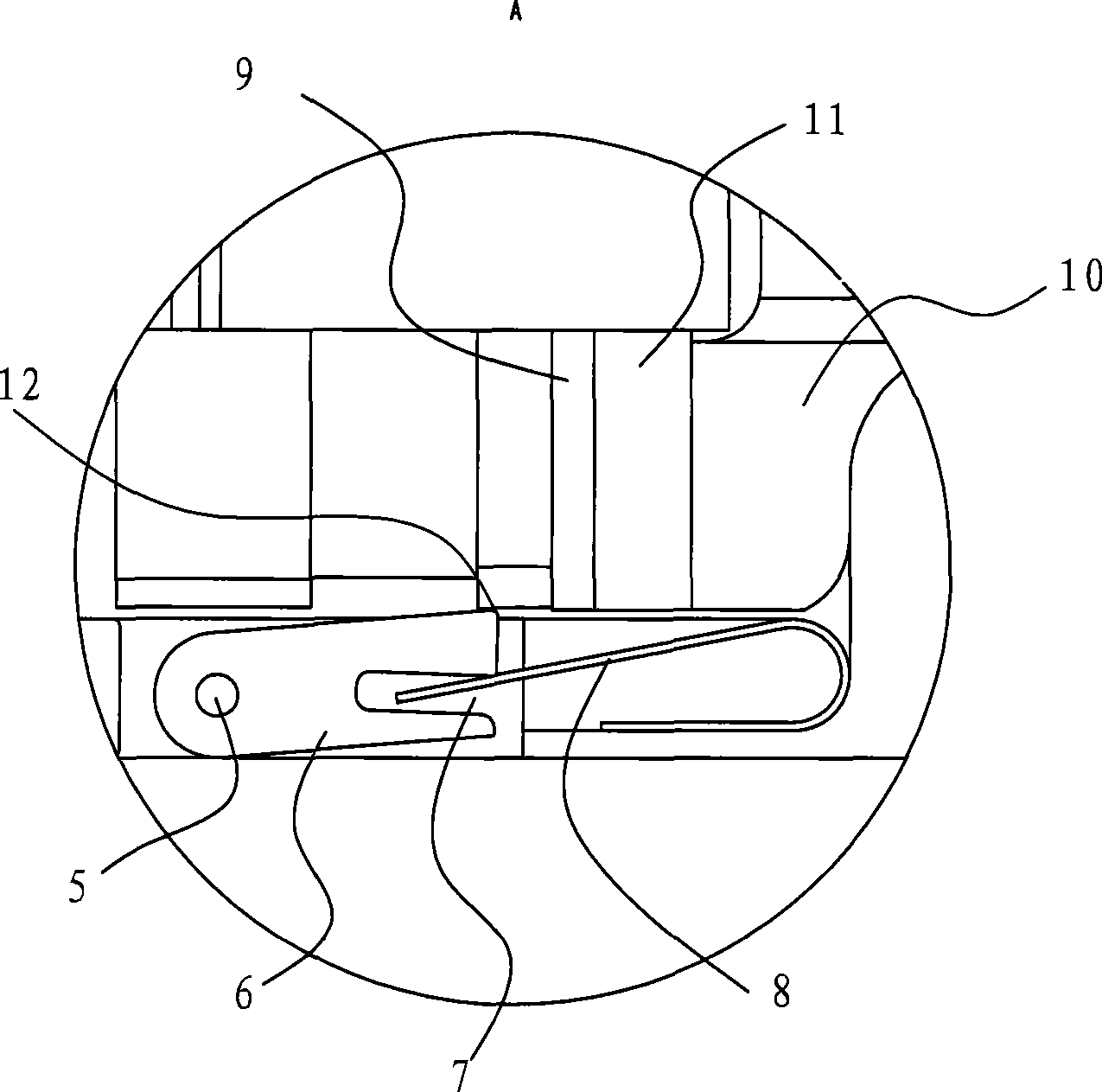

[0016] As shown in Figure 1, a stapler includes a main body 1, a staple cartridge 2 disposed on the main body 1, a nail pusher 9 disposed inside the staple cartridge 2, and a staple pusher 9 disposed on the body 1 for pushing the staple pusher 9. In this embodiment, the front end of the main body 1 is fixedly connected with a staple cartridge base 3, the staple cartridge 2 and the nail abutment seat 4 are all arranged on the staple cartridge base 4, and the front end of the push rod 10 has a nail pushing plate 9 The pushing part 11 that is in contact, in order to make the empty staple bin can be locked after suturing, the lower end surface of the pushing part 11 in the present invention is flush with the lower end surface of the nail pushing piece 9, and a stopper is pressed below the nail pushing piece 9 Block 6, the block 6 is connected with a reset mechanism that makes it pop up.

[0017] In order to save space in the staple cartridge 2, in this embodiment, a groove 7 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com