Method for improving undercut flaw of phosphorosilicate glass

A technology of phosphosilicate glass and defects, which is applied in the field of improving undercut defects of phosphosilicate glass, can solve the problems of undercut defects of phosphosilicate glass, undercut defects, and high phosphorus content of phosphosilicate glass, so as to avoid undercut defects, The effect of avoiding unexpected problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the improved method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

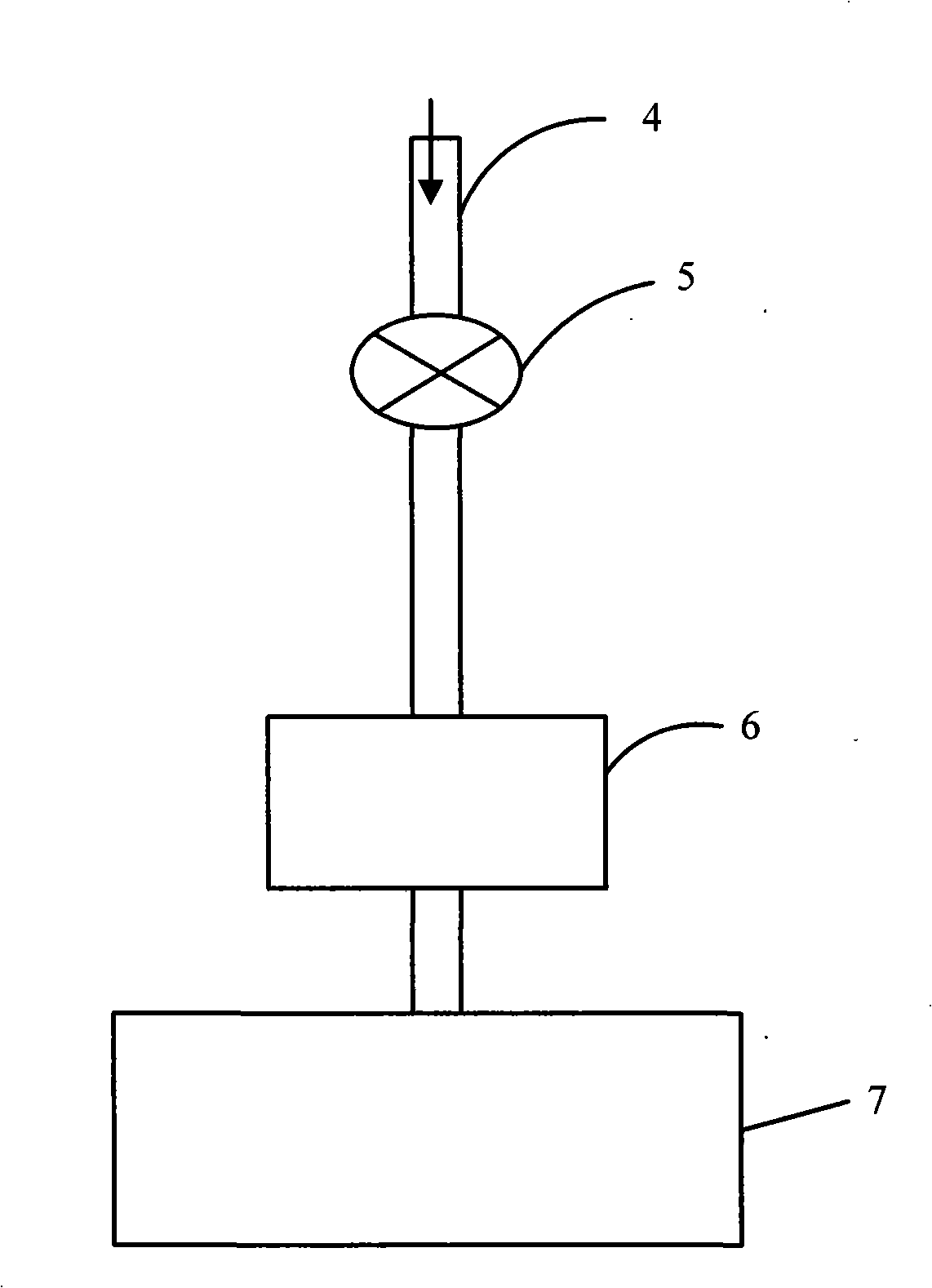

[0010] see figure 2 The process chamber 7 for preparing phosphosilicate glass is connected with several gas pipelines for transporting reaction gases, wherein the pipeline 4 is used for transporting phosphine gas. The pipeline 4 is provided with an on-off valve 5 and a flow controller 6 located between the process chamber 7 and the on-off valve 5, and the flow controller 6 can accurately control the flow of the phosphine gas.

[0011] The improvement method provided by the present invention is to suck away the phosphine gas remaining between the on-off valve 5 and the flow controller 6 before opening the on-off valve 5 . In this embodiment, the flow controller 6 is opened first to release the residual phosphine gas into the process chamber 7 . After all the remaining phosphine gas is sucked away, the on-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com