Sanding head straight reciprocating motion apparatus for sander

A reciprocating linear motion, sanding machine technology, applied in the field of sanding machines, can solve problems such as waste, inappropriateness, and indentation on the surface of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

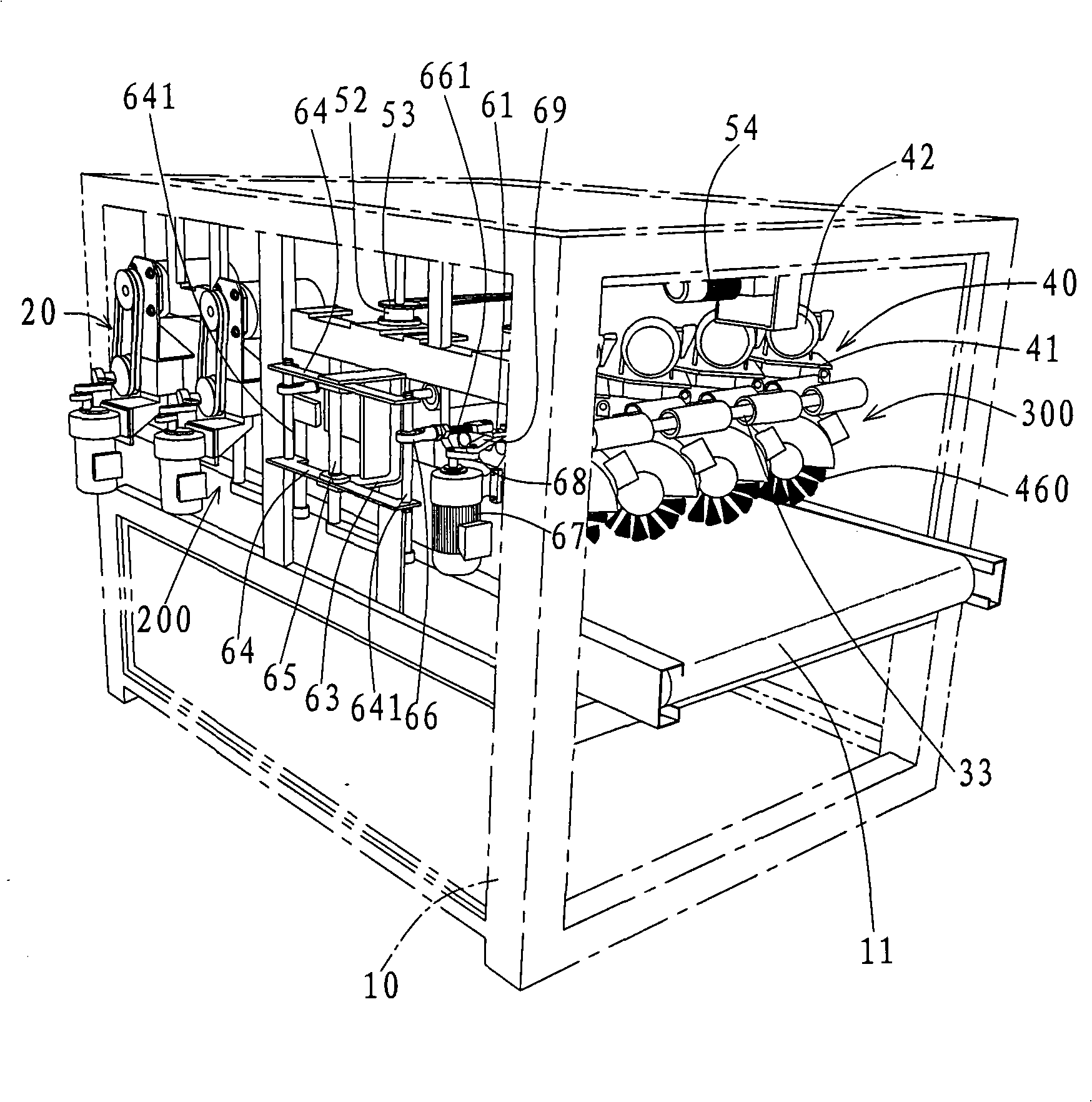

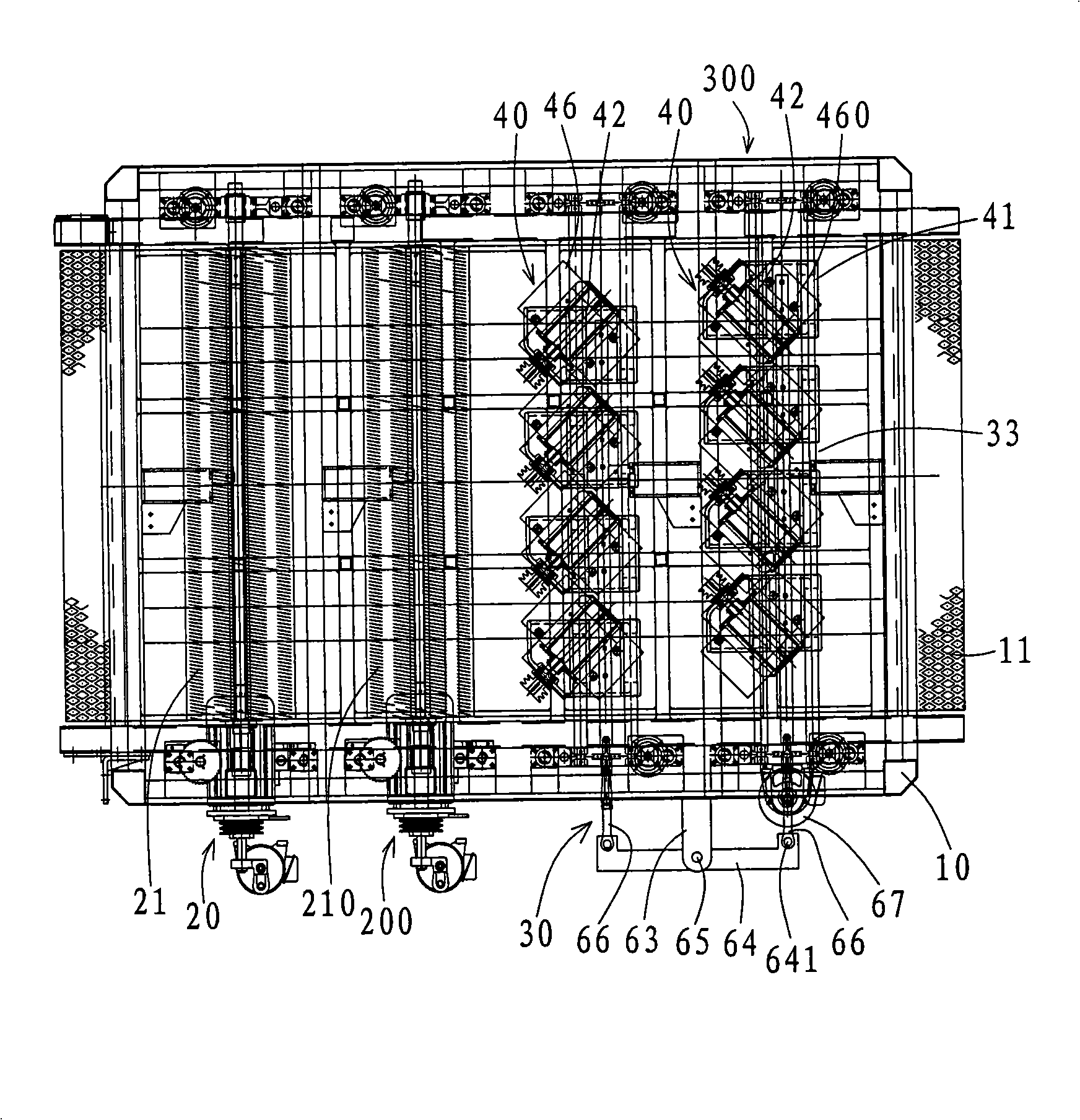

[0048] refer to Figure 1 to Figure 3 As shown, the present invention includes:

[0049] A chassis 10, a conveyor belt 11 horizontally wound around the front and back of the chassis 10, a first and second set of sanding devices 20, 200 and a third and fourth set of sanding devices 30 across the top of the conveyor belt 11, constituted by 300;

[0050] Its first and second groups of sanding devices 20, 200 are pivotally provided with a sanding element driven by a rotating shaft at the pivot above the front half of the conveyor belt 11 of the cabinet 10, and the sanding element can be an emery cloth silk wheel 21, 210, and make the first and second groups of sanding devices 20,200 controlled by a lifting transmission device that is respectively arranged, so that the two emery cloth wire wheels 21 and 210 can be engaged in height adjustment respectively, and the first and second groups of sanding devices 20 , 200 and control the displacement of the first and second groups of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com