Manufacturing method of tungsten-yttrium electrode

A manufacturing method and electrode technology, applied in the field of electrode manufacturing, can solve the problems of inability to meet corresponding requirements, uneven tungsten-yttrium coating powder, small penetration depth at high current, etc., and achieve reduced process, stable welding performance, and improved electrical conductivity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for manufacturing a tungsten-yttrium electrode. The tungsten-yttrium electrode is manufactured by combining powder metallurgy and pressure processing. The method is carried out according to the following steps, specifically including:

[0029] a. After uniformly mixing the yttrium nitrate aqueous solution into the solid raw material by spray doping, heating and drying to make tungsten-yttrium coated powder; wherein, the solid raw material can be ammonium paratungstate (APT) or tungsten trioxide (WO 3 any of );

[0030] b. The obtained tungsten-yttrium coated powder is reduced twice to obtain tungsten-yttrium powder, which is pressed and sintered at high temperature to make a tungsten-yttrium billet;

[0031] c. The obtained tungsten-yttrium billet is made into a tungsten-yttrium electrode by means of pressure processing and forging.

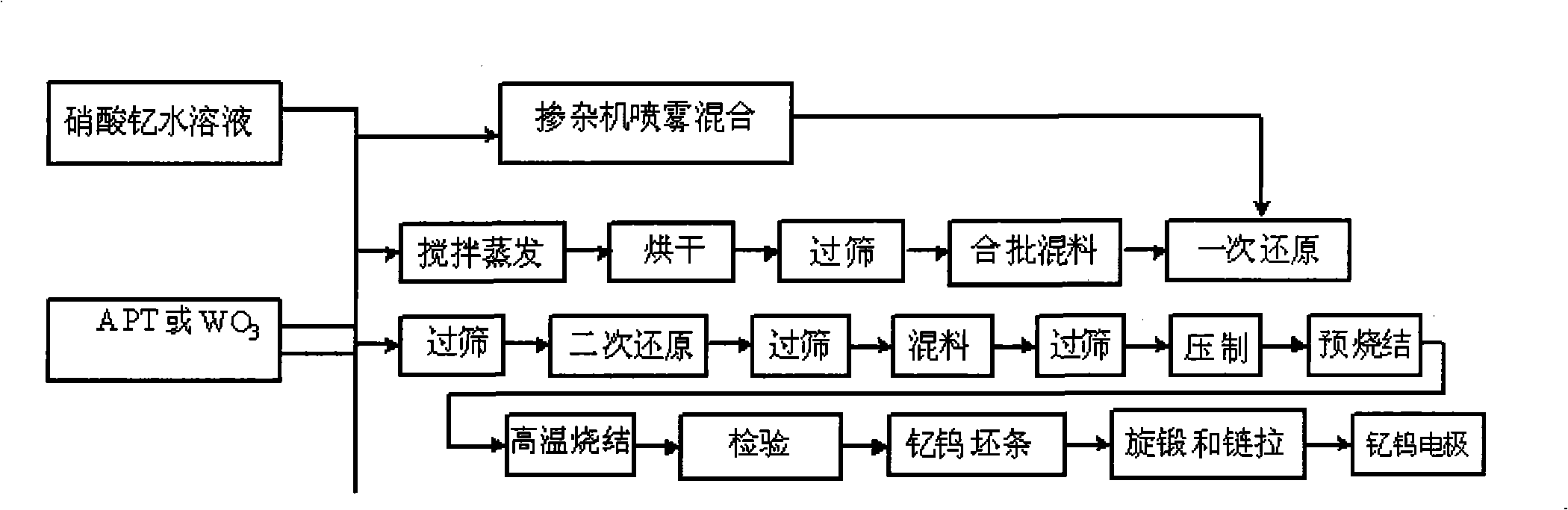

[0032] In practice, the above method can refer to figure 1 The process shown is processed, including:...

Embodiment 2

[0038] The present embodiment provides a kind of method of manufacturing tungsten yttrium electrode, specifically comprises:

[0039] a. Preparation of tungsten yttrium coated powder:

[0040] The aqueous solution prepared by yttrium nitrate and the solid raw material ammonium paratungstate APT are doped in the doping machine, and the tungsten-yttrium coated powder is prepared by spray drying and other processes, as follows:

[0041] ① Dissolve 13.5-15kg of yttrium nitrate in 15L of deionized water according to the grade requirements of the produced tungsten yttrium electrode to make an aqueous solution of yttrium nitrate for use;

[0042] ②Put 450Kg of ammonium paratungstate (APT) into the doping machine, and spray 15L of yttrium nitrate aqueous solution with a concentration of 0.9-1.0g / ml into the doping machine. During the spraying process, a vacuum device can be used. Realize spray coating on ammonium paratungstate APT;

[0043] ③ The injection speed is 25ml / min, and the...

Embodiment 3

[0047] This embodiment also provides a method for manufacturing a tungsten yttrium electrode, which specifically includes:

[0048] Preparation of tungsten yttrium coated powder: the aqueous solution prepared by yttrium nitrate and the solid raw material tungsten trioxide (WO 3 ), the tungsten-yttrium coated powder prepared by doping, spray drying and other processes in the doping machine, the details are as follows:

[0049] ① Dissolve 23-24kg of yttrium nitrate in 15L of deionized water according to the grade requirements of the produced tungsten-yttrium electrode to make an aqueous solution for use;

[0050] ② 450Kg of tungsten trioxide (WO 3 ) into the doping machine and spray the configured 15L yttrium nitrate aqueous solution into the doping machine;

[0051] ③ The injection speed is 45ml / min, and the injection time is 30 minutes to 45 minutes;

[0052] ④ About 20 minutes after spraying liquid, send in steam, when the steam pressure is 0.15-0.3Mpa, and the steam tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com