Nano-catalyst of sodium aluminum hydride complex hydride as well as preparation method and application thereof

A nano-catalyst and coordination hydride technology, which is applied in the direction of physical/chemical process catalysts, metal hydrides, chemical instruments and methods, etc., can solve the problems that cannot be adapted to large-scale industrial production applications, large molecular weight, and lack of hydrogen storage capacity, etc. problem, achieve good catalytic activity and stability, good activity and stability, and improve the effect of reversible hydrogen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The NaH, Al, Ti and C raw materials used are all commercial materials, NaH purity ≥ 95%, particle size 74 μm, Al powder purity ≥ 99%, particle size 74-154 μm, Ti purity ≥ 99%, particle size 0.5 C 0.5 The stoichiometric ratio of the corresponding elemental Ti and C powders was weighed and uniformly mixed in an agate mortar, and then cold-pressed under a pressure of 20 MPa into a cold-pressed block with a diameter of 20 mm and a thickness of about 15 mm; the cold-pressed block was heated at 800 ° C Diffusion sintering for 5 hours under a protective argon atmosphere and cooled with the furnace, then the sintered block was taken out and mechanically crushed to 100 mesh, and the crushed powder was put into the agate ball mill jar of a vibrating ball mill for 8 hours to obtain Ti 0.5 C 0.5 The catalyst is ultrafine powder, the vibration frequency is 1200 times per minute, the ball to material ratio in the ball milling process is 30:1, the protective atmosphere of the ball mil...

Embodiment 2

[0026] The raw material parameters used in the experiment and the prepared Ti 0.5 C 0.5 The process of the catalyst is the same as in Example 1. The mixed powder of NaH and Al (the molar ratio of NaH to Al is 1:1) was mixed with the Ti prepared above 0.5 C 0.5 Catalyst is put into the agate ball mill tank of vibrating ball mill after being uniformly mixed according to the molar ratio of 1:0.10, ball mills 5h under 1.2MPa hydrogen (purity ≥ 99.99%), the ball material ratio of ball milling process is 10:1, to prepare ( Na+Al)+10mol%Ti 0.5 C 0.5 Hydrogen storage material.

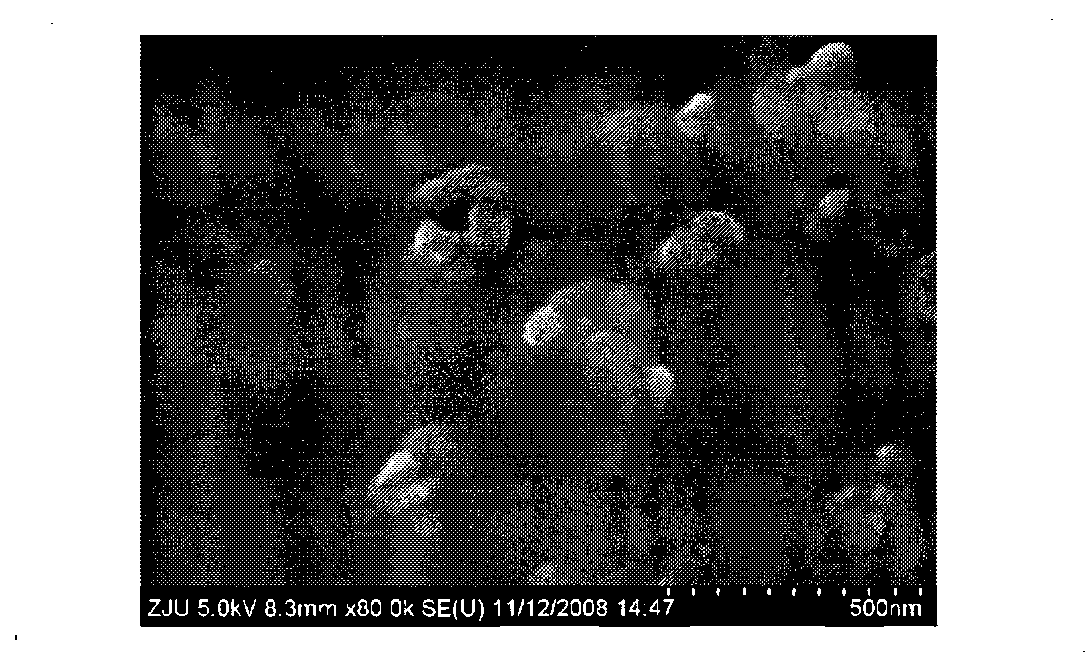

[0027] figure 2 It is (Na+Al)+10mol%Ti 0.5 C 0.5 SEM image after ball milling for 5 h. It can be seen that the particle size of the synthesized hydrogen storage material is between 50nm and 80nm.

Embodiment 3

[0029] The raw material parameters used in the experiment and the prepared Ti 0.5 C 0.5 The process of the catalyst is the same as in Example 1. The mixed powder of NaH and Al (the molar ratio of NaH to Al is 1:1) was mixed with the Ti prepared above 0.5 C 0.5 Catalyst is put into the agate ball mill tank of vibratory ball mill after being uniformly mixed according to the molar ratio of 1:0.10, ball mills 5h under 0.5MPa hydrogen (purity ≥ 99.99%), the ball material ratio of ball milling process is 30:1, to prepare ( Na+Al)+10mol%Ti 0.5 C 0.5 Hydrogen storage material.

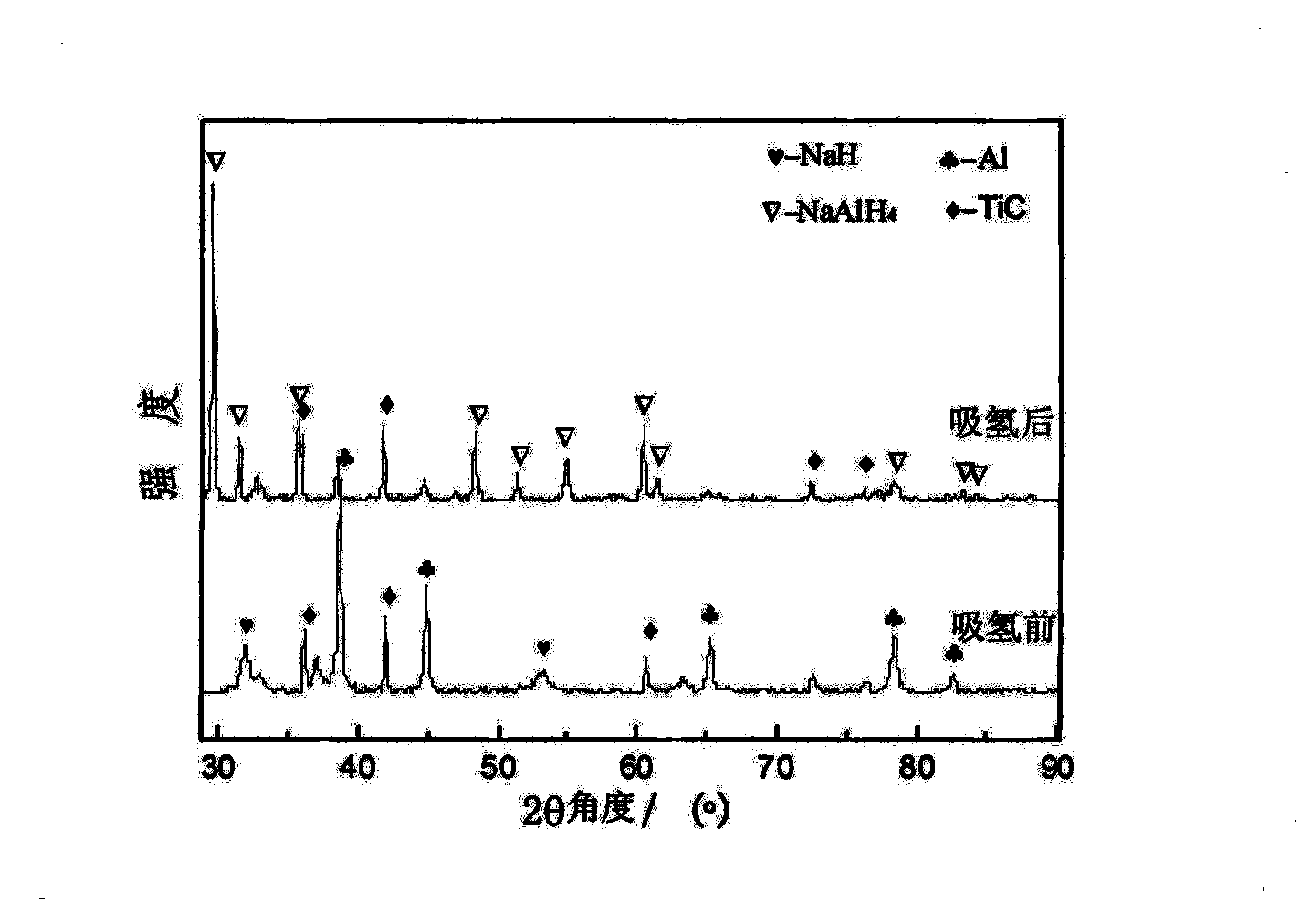

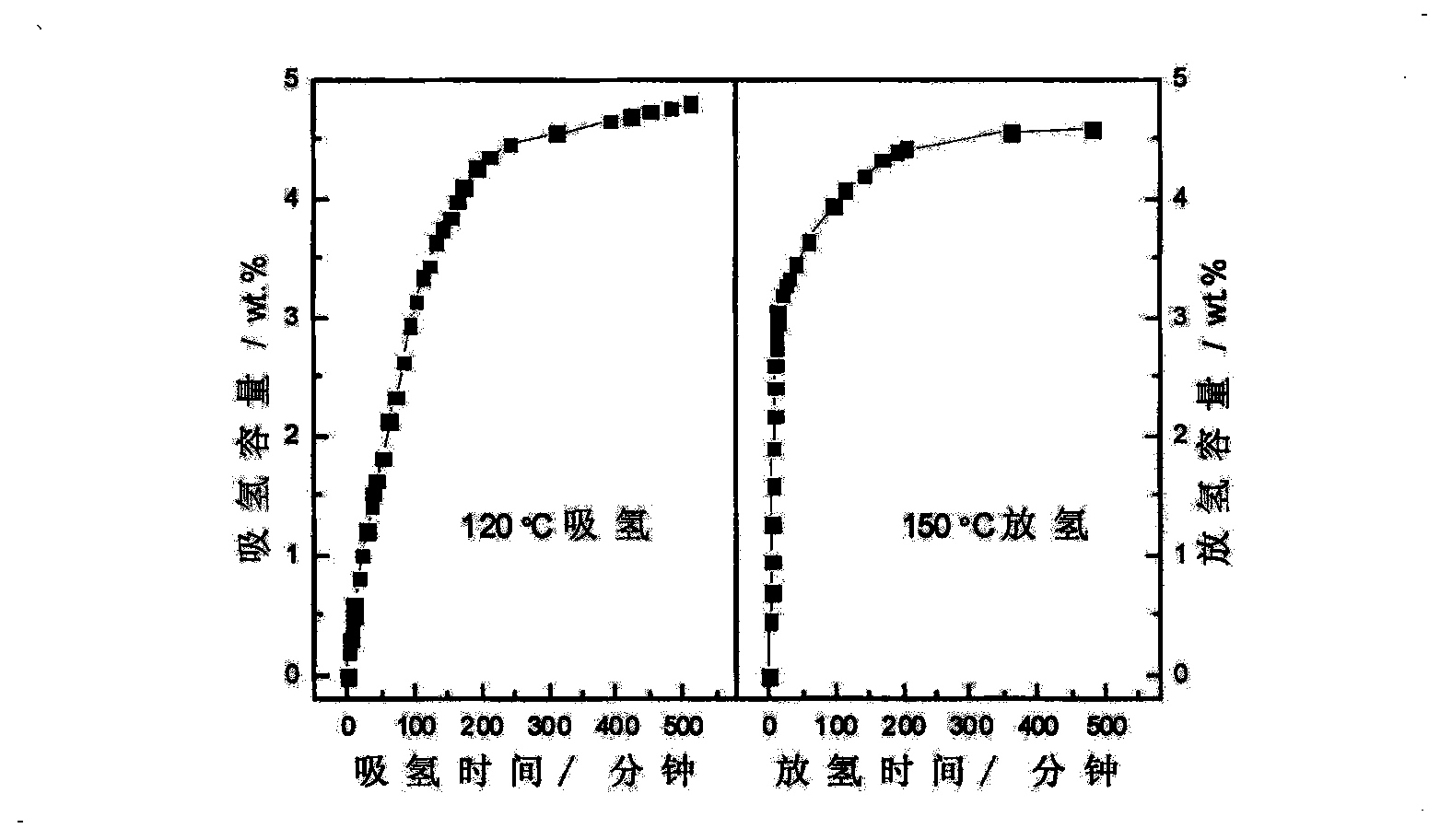

[0030] image 3 It is (Na+Al)+10mol%Ti 0.5 C 0.5 Kinetics of hydrogen absorption and desorption for the first time after ball milling for 5 hours. It can be seen that the as-prepared hydrogen storage material has a hydrogen absorption capacity of 4.80 wt.% after hydrogen absorption at 120°C for 8 hours, and a hydrogen desorption amount of 4.57 wt.% after dehydrogenation at 150°C for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com