Solvent-free composite glue-mixing mechanism

A solvent-free, glue-mixing technology, applied in mixers, dissolvers, mixer accessories, etc., can solve problems such as unsuitable operation needs, unsightly structure and safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

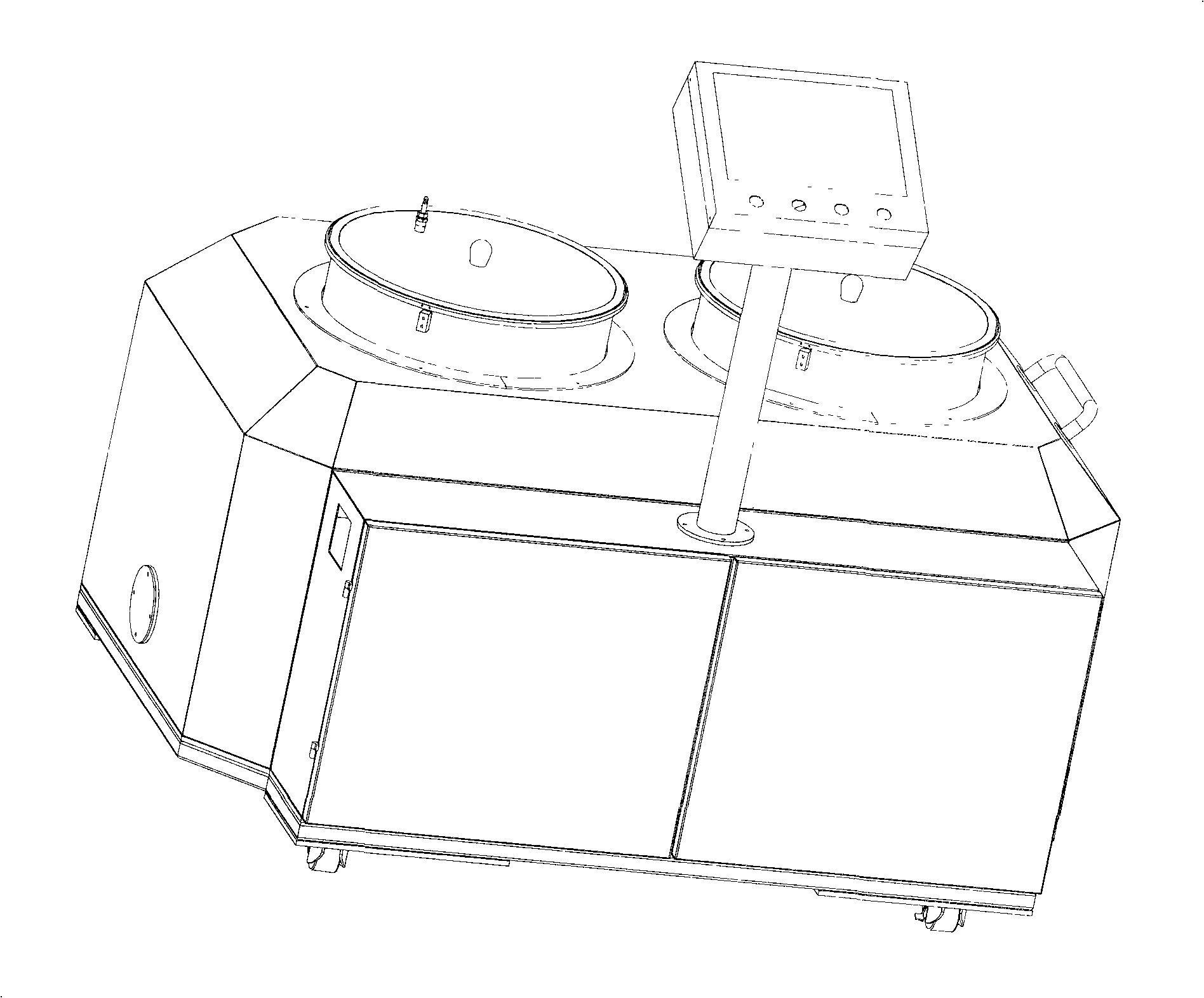

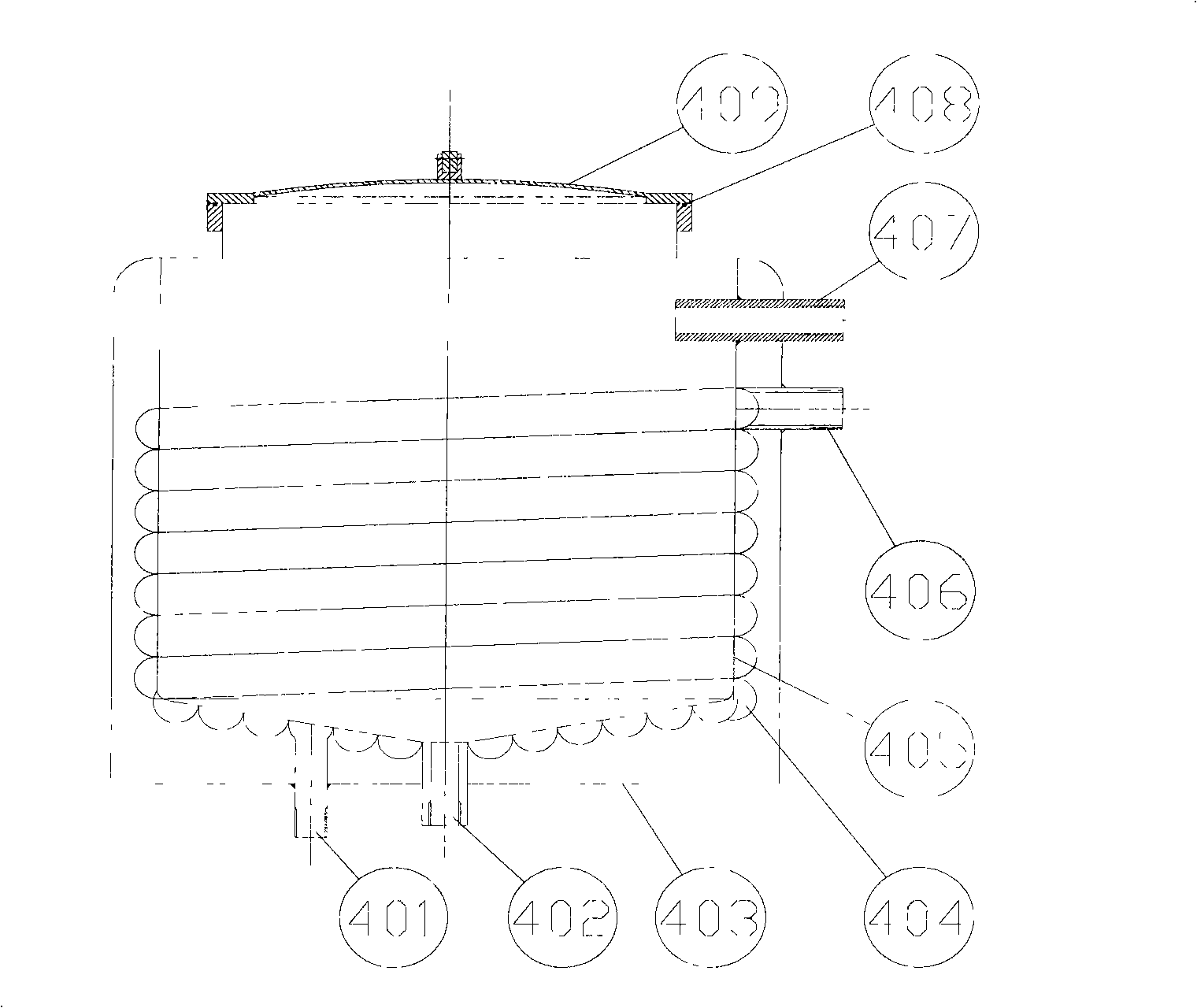

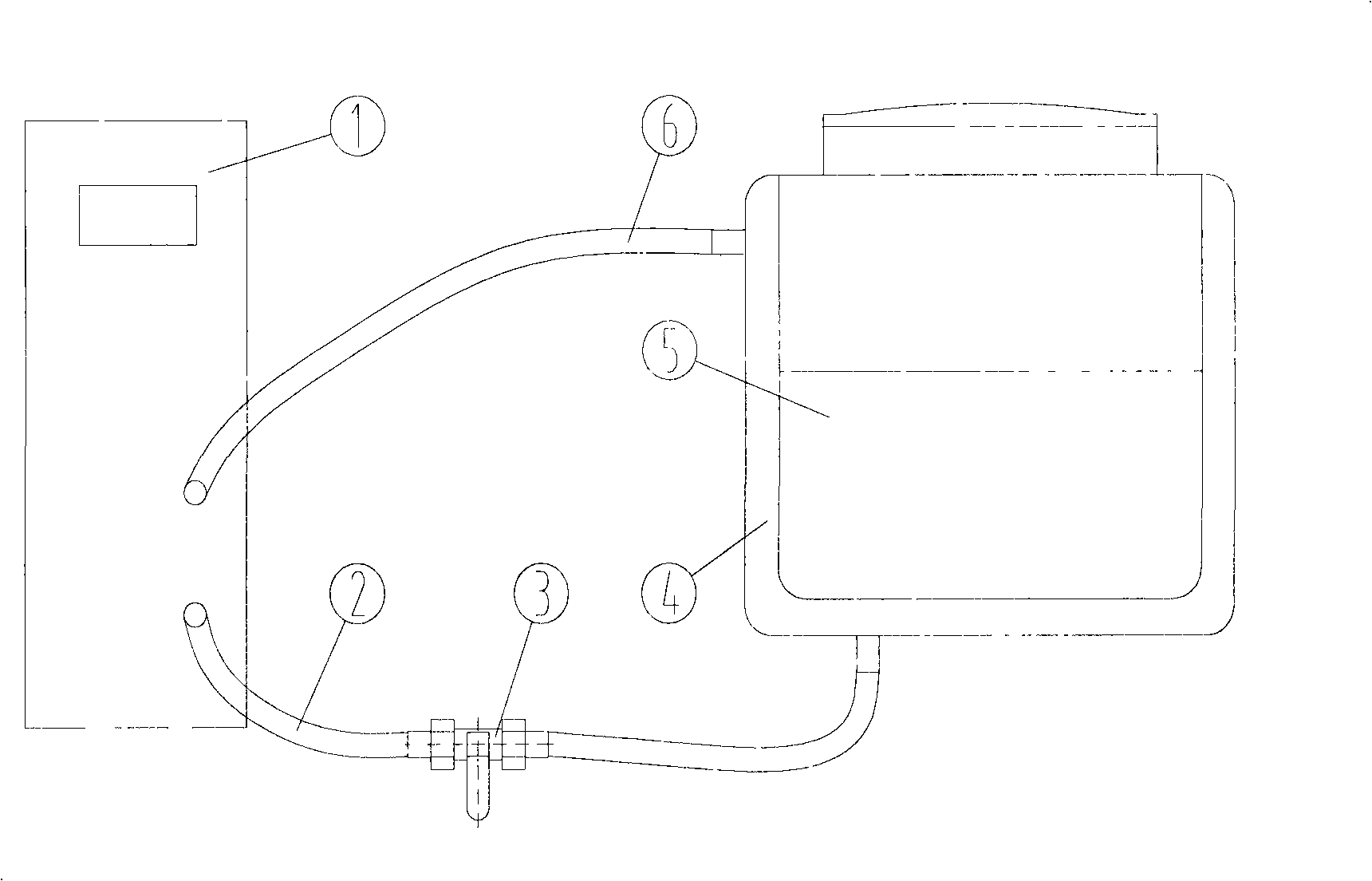

[0015] Please refer to figure 1 , the solvent-free composite glue mixing mechanism consists of a rack, a spiral heated double-layer barrel device, a two-component glue ratio detection and control device, an inflatable dehumidification and pressure-holding device, and an inflatable pipeline for quick-change joints. The system composition is characterized in that: the wall of the double-layer barrel device with spiral heating is made of double-layer stainless steel plate, and adopts the heating method of water inlet from the bottom of the barrel, spiral heating in the middle and water outlet from the upper part; the ratio detection of the two-component glue and The control device accurately measures online and real-time adjusts the flow rate and proportion of the two-component glue; its inflatable dehumidification and pressure-holding device prevents the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com