Polymer battery packaging structure

A packaging structure, polymer technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of space limitation of the volume-to-capacity ratio of cells, difficult to achieve, and no solutions have been found, so as to improve battery capacity. Volume ratio, the effect of realizing the volume of the cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

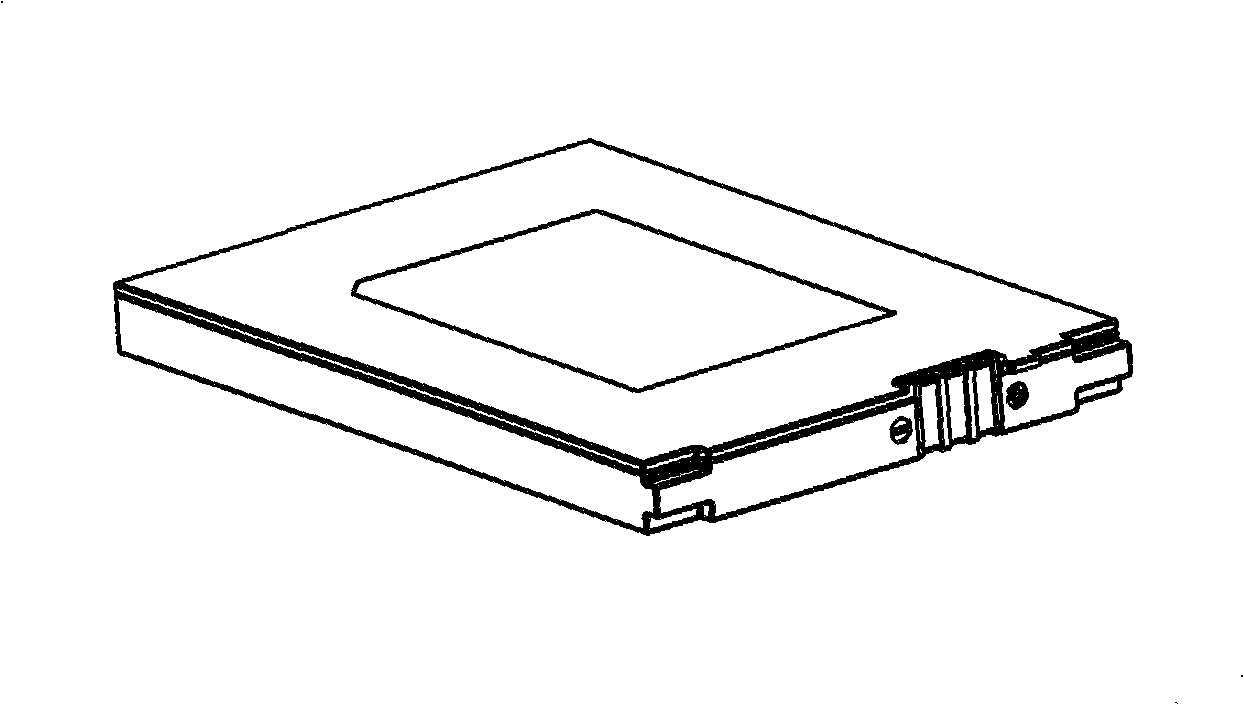

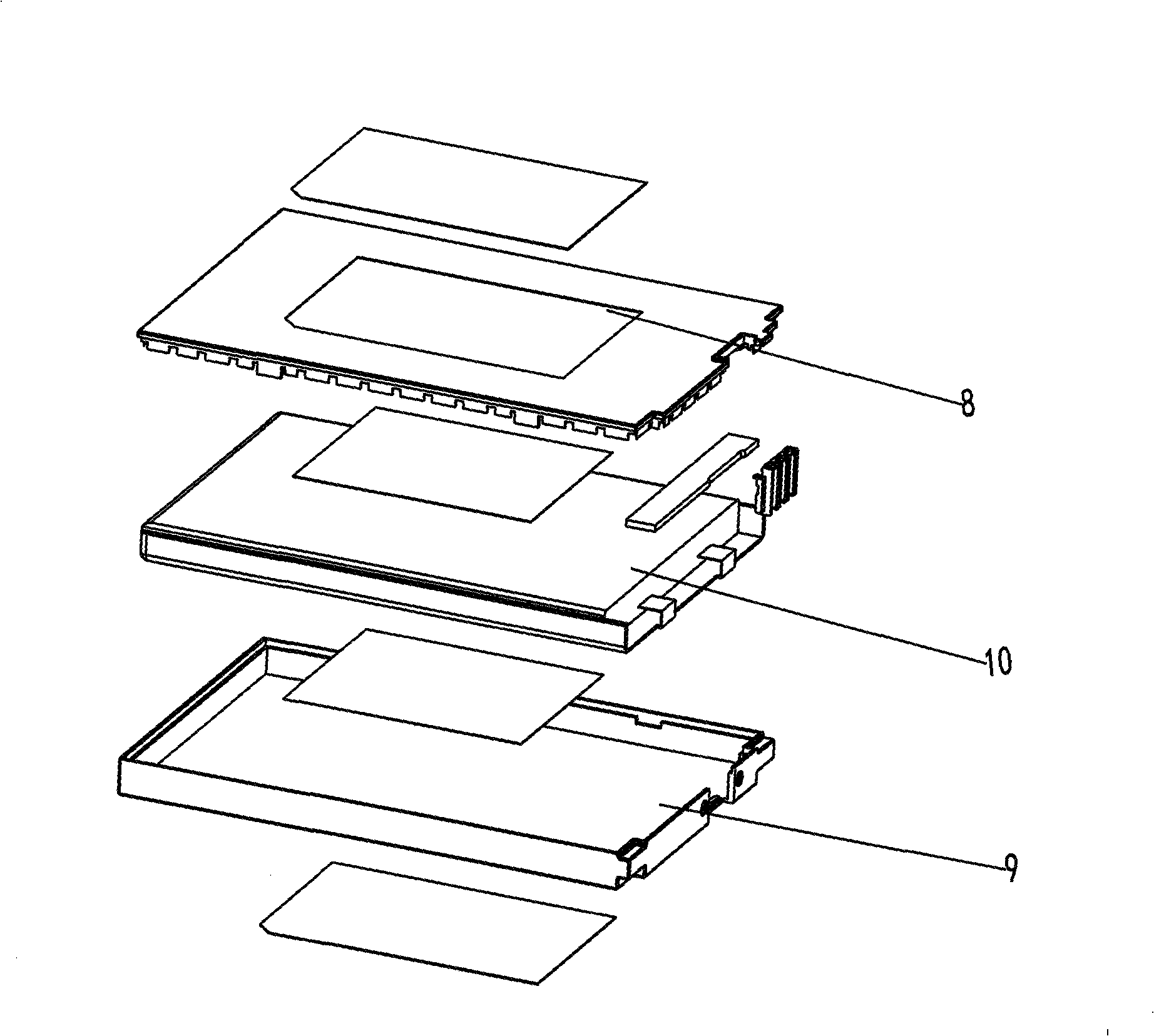

[0044] see Figures 8 to 13 , a packaging structure of a polymer battery, including a battery cell unit, a battery cell protection unit, a battery head part and a battery tail part, wherein the battery cell unit is fixed in the battery cell protection unit, the battery head assembly and the battery cell The unit is electrically connected, the battery head assembly and the battery tail assembly are partially connected and fixed with the cell protection unit, and the cell protection unit forms the shape of the battery with the battery head assembly and the battery tail assembly.

[0045] The cell protection unit is made of a sheet made of metal or plastic, or metal and plastic material from 0.02MM to 0.30MM to form a box-shaped body 40. The box-shaped body can be made of one sheet-shaped body or two Or more than two box-shaped bodies are butted to form.

[0046]The cell unit is packaged in the box-shaped body of the cell protection unit by means of a sheet-like viscous filling ...

Embodiment 2

[0052] see Figures 14 to 18 , this embodiment is similar to the battery packaging structure of Embodiment 1. The battery head part is also composed of the battery head shape parts and the safety protection circuit board. The battery head shape parts are in the form of plastic clad steel or bonding form and the safety protection circuit The boards are connected, and the safety protection circuit board is connected to the battery core for circuit conduction.

[0053] The battery tail part is composed of plate-shaped battery tail shape parts, and the protective unit box-shaped body processed by a sheet made of metal or plastic, or metal and plastic materials, and the connection between the battery head part and the battery tail part or plastic deformation. A zigzag body 401 is provided at the two ends of the cell protection unit sheet connected to the head and tail of the cell, and corresponding card slots 201 are provided on the battery head part and the battery tail part. Whe...

Embodiment 3

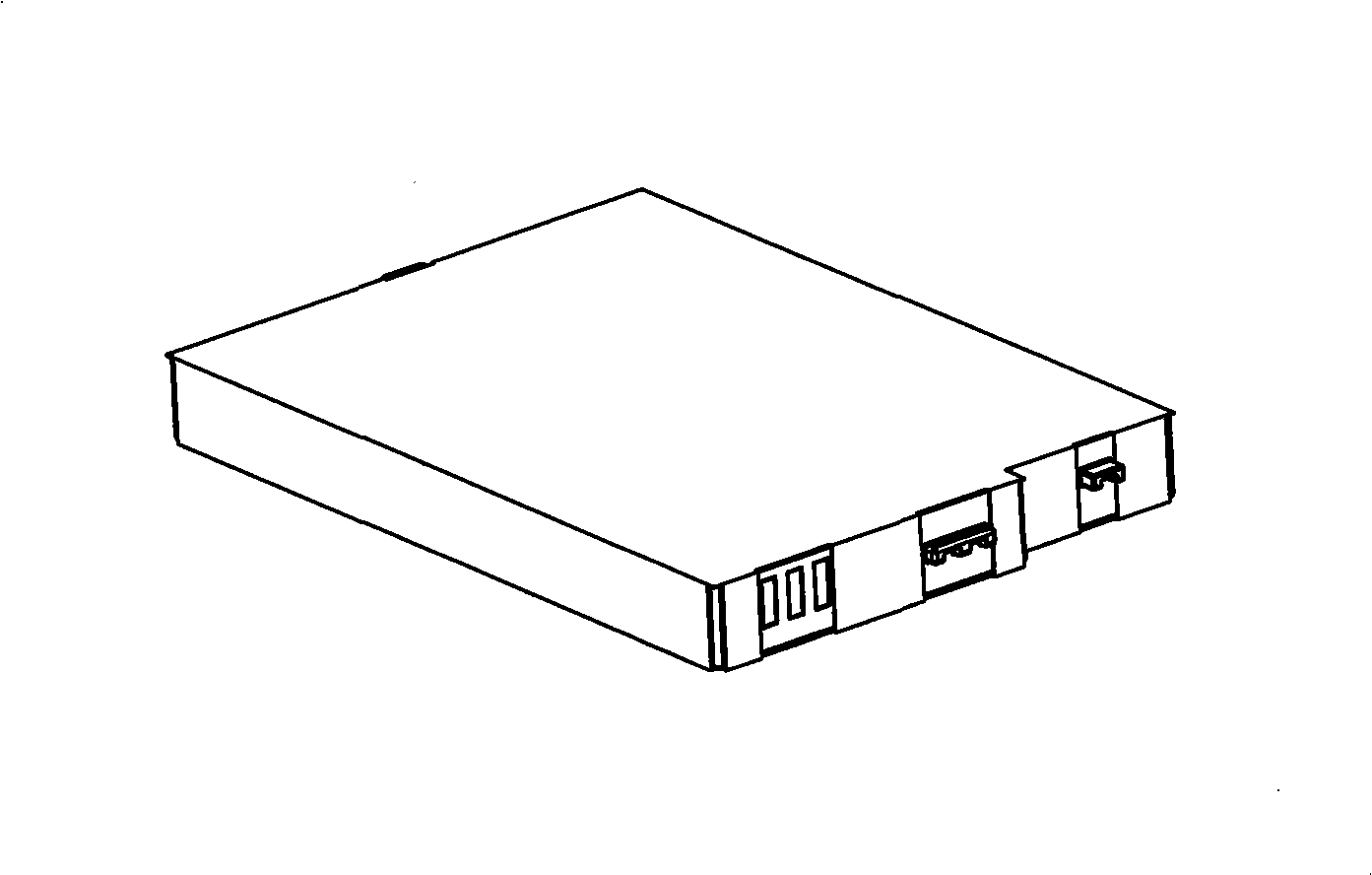

[0055] see Figure 19 The difference between this embodiment and Embodiment 1 is that the battery head part and the battery tail part form a zigzag frame body 5 through the connecting piece, and the battery cell unit is arranged in the frame body, and the thickness is 0.02MM to 0.30MM The metal sheet, or the box-shaped cell protection unit with openings at both ends made by mating the metal sheet and the plastic sheet is connected outside the frame body. The cell protection unit is connected to the frame body formed by the battery head part and the battery tail part through metal elastic deformation.

[0056] After the box-shaped body of the cell protection unit is installed and matched with the frame body, stamping deformation positions 402 are formed on both ends of the box-shaped body. The stamping deformation positions press together the battery head part and the battery tail part to form an integrated packaging structure.

[0057] Of course, it is also possible to punch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com