High-temperature high-pressure difference pressure-reducing valve

A high-temperature, high-pressure, pressure-reducing valve technology, which is applied in the field of pressure-reducing valves, can solve problems such as unsuitable solid particles, small orifice holes, dead angles in pipelines, etc., and achieve the effects of simple structure, reduced erosion and wear, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

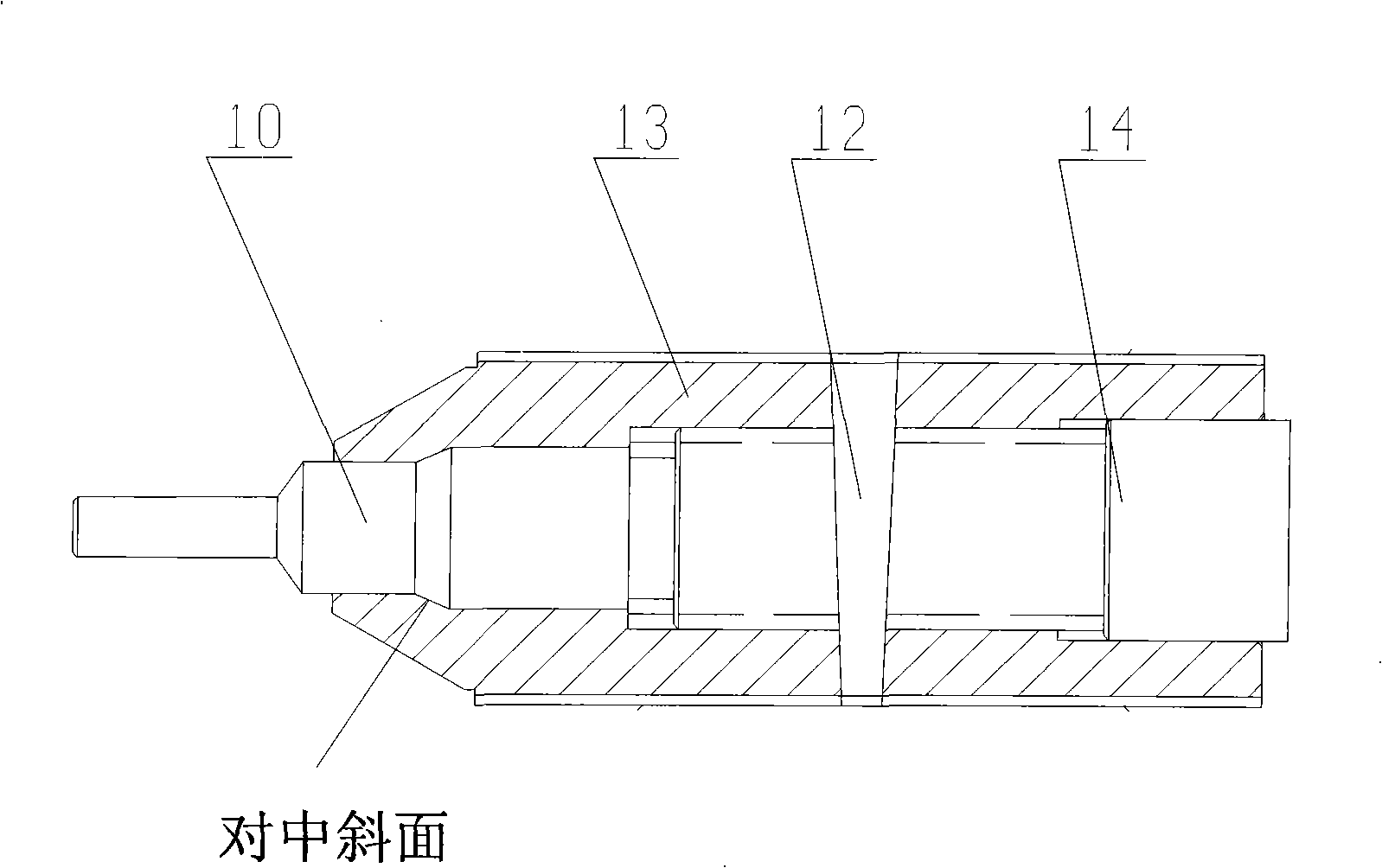

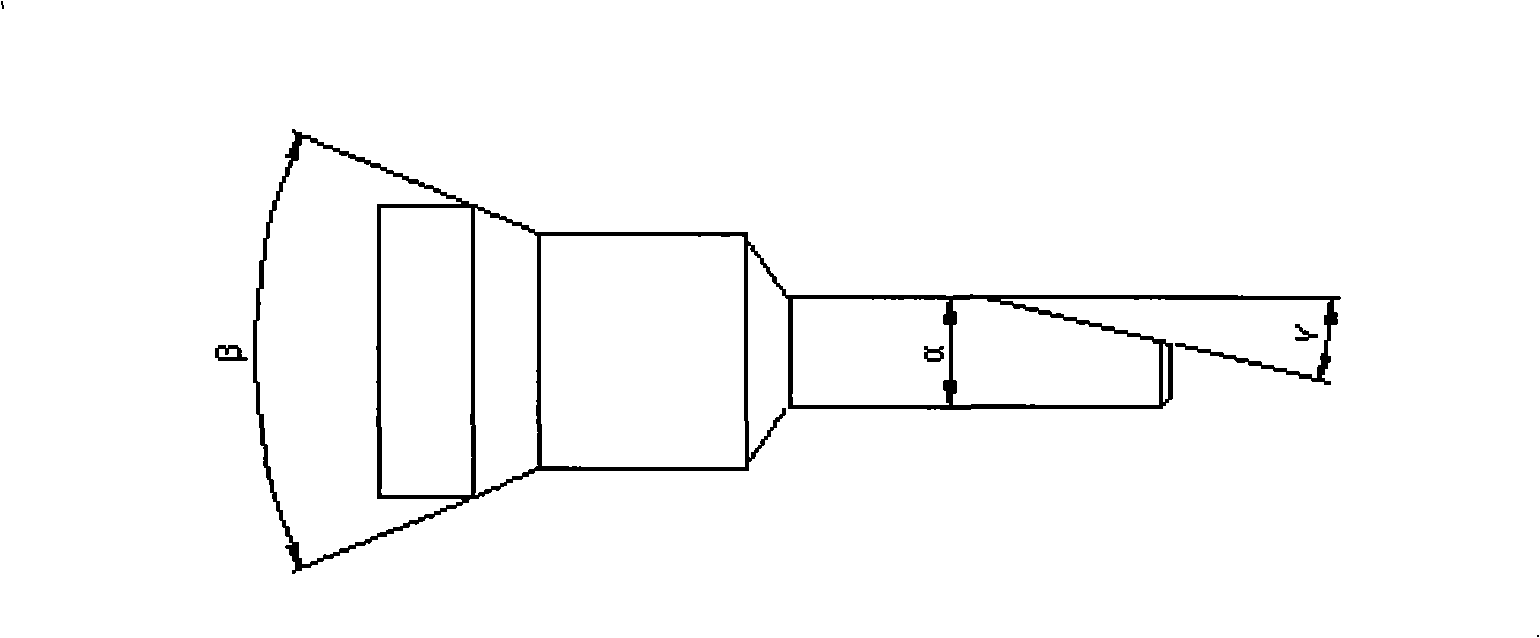

[0032] As shown in Figures 1 to 5, a high-temperature and high-pressure differential pressure reducing valve includes a valve body 15, a valve seat 8, and a valve core 10 that is inside the valve seat 8 and can move up and down within it. The thread and pin 12 are fixedly connected with the valve stem 14, the valve stem 14 is located inside the valve body 15, sealed with the outside world by the sealing packing 16 and the packing gland 17, and can move up and down, the packing gland 17 is connected with the valve body 15 by bolts 18 , The lower part of the valve seat 8 is provided with a bushing 2, a throttle orifice 5, and a flange 4 and a bolt 3 connected to the outside.

[0033] The medium enters the valve cavity from the side, passes through the channel formed by the valve core 10 and the valve seat 8 and the throttle orifice 5 downstream of the valve seat, and then flows out from the outlet body 1 at the tail end. The valve body 15 is the main part, which contains the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com