Thermal treatment process for quick cutting steel composite roll

A composite roll and high-speed steel technology, which is applied in the heat treatment process of high-speed steel composite rolls, can solve the problems of difficult heat treatment temperature and holding time, and achieve the effects of improving machinability, small hardness drop, and preventing large residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The trade mark of the high-speed steel of the present embodiment is 1.8C-5Mo-4Cr-5V, according to the heat treatment process of the high-speed steel composite roll of the present invention, the high-speed steel composite roll is heat-treated, adopting the following process parameters:

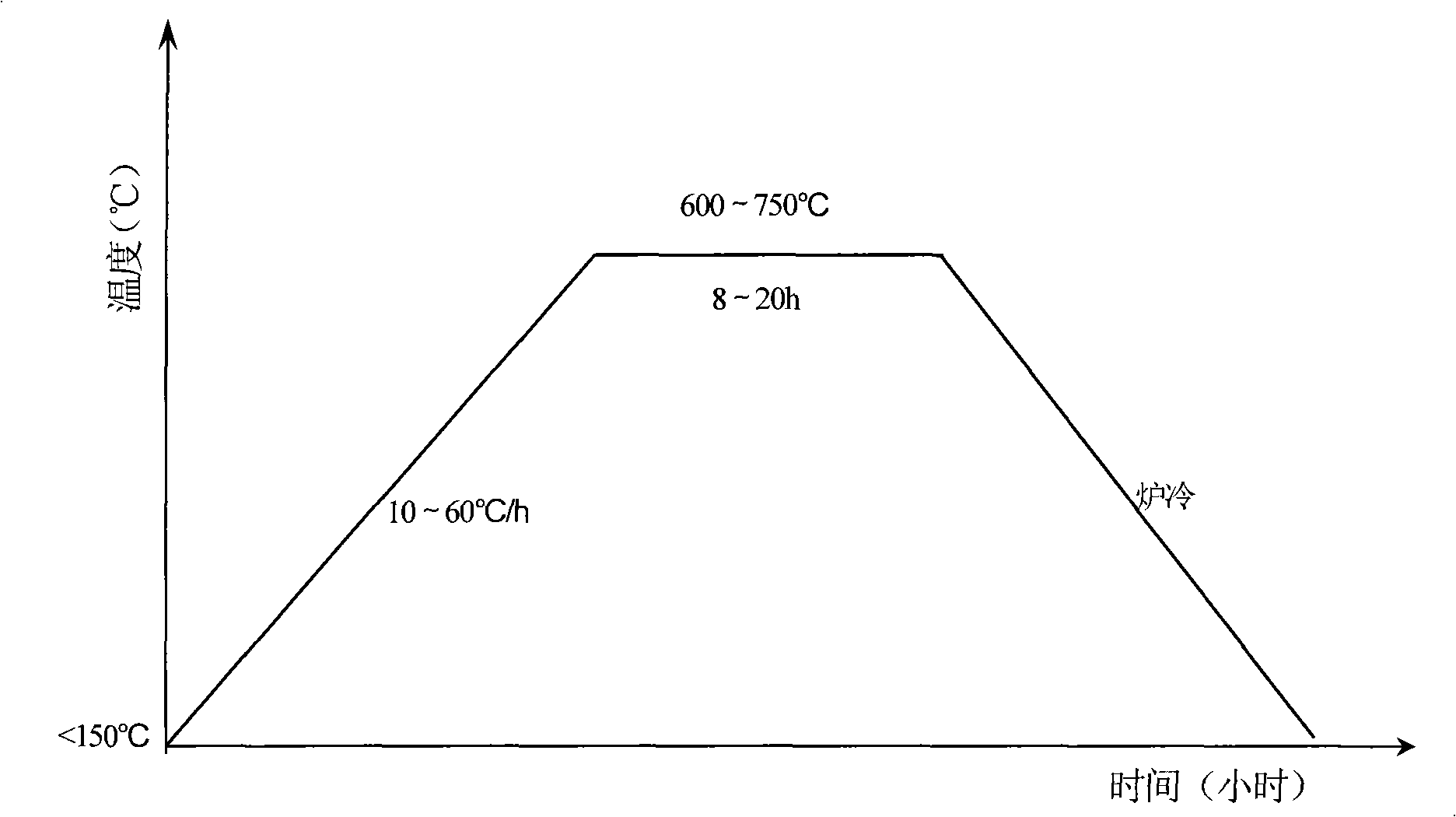

[0025] (1) Annealing

[0026] Annealing heating rate: 20°C / h; annealing heating temperature: 630°C; annealing holding time: 10h, furnace cooling.

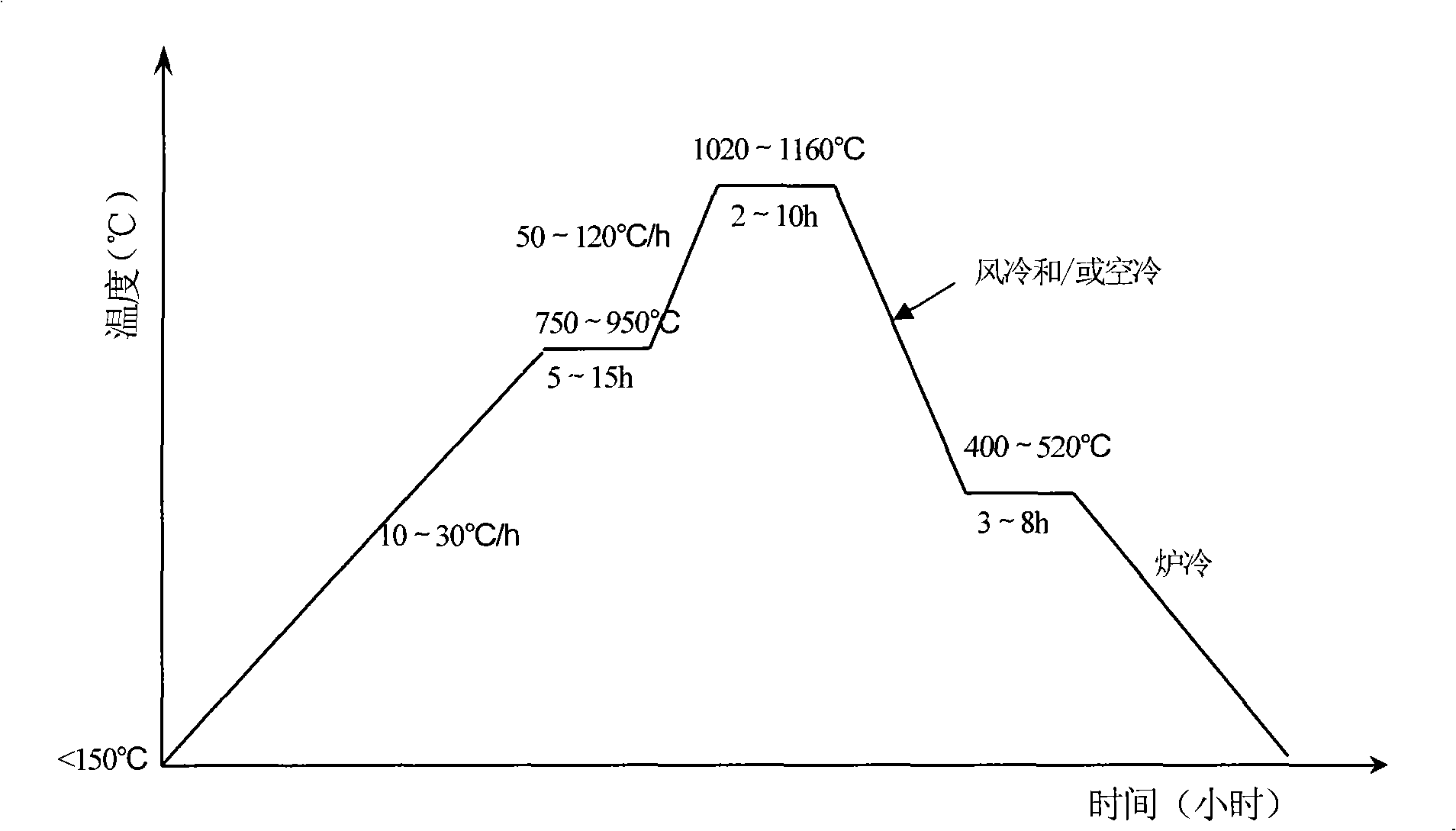

[0027] (2) Quenching

[0028] Heating rate in the initial stage of quenching: 15°C / h; primary holding temperature: 780°C; primary holding time: 5h; secondary heating rate in quenching: 60°C / h; austenitizing temperature: 1050°C; austenitizing time : 8h; quenching cooling method: air cooling; quenching furnace temperature: 420 ℃; furnace holding time: 6h.

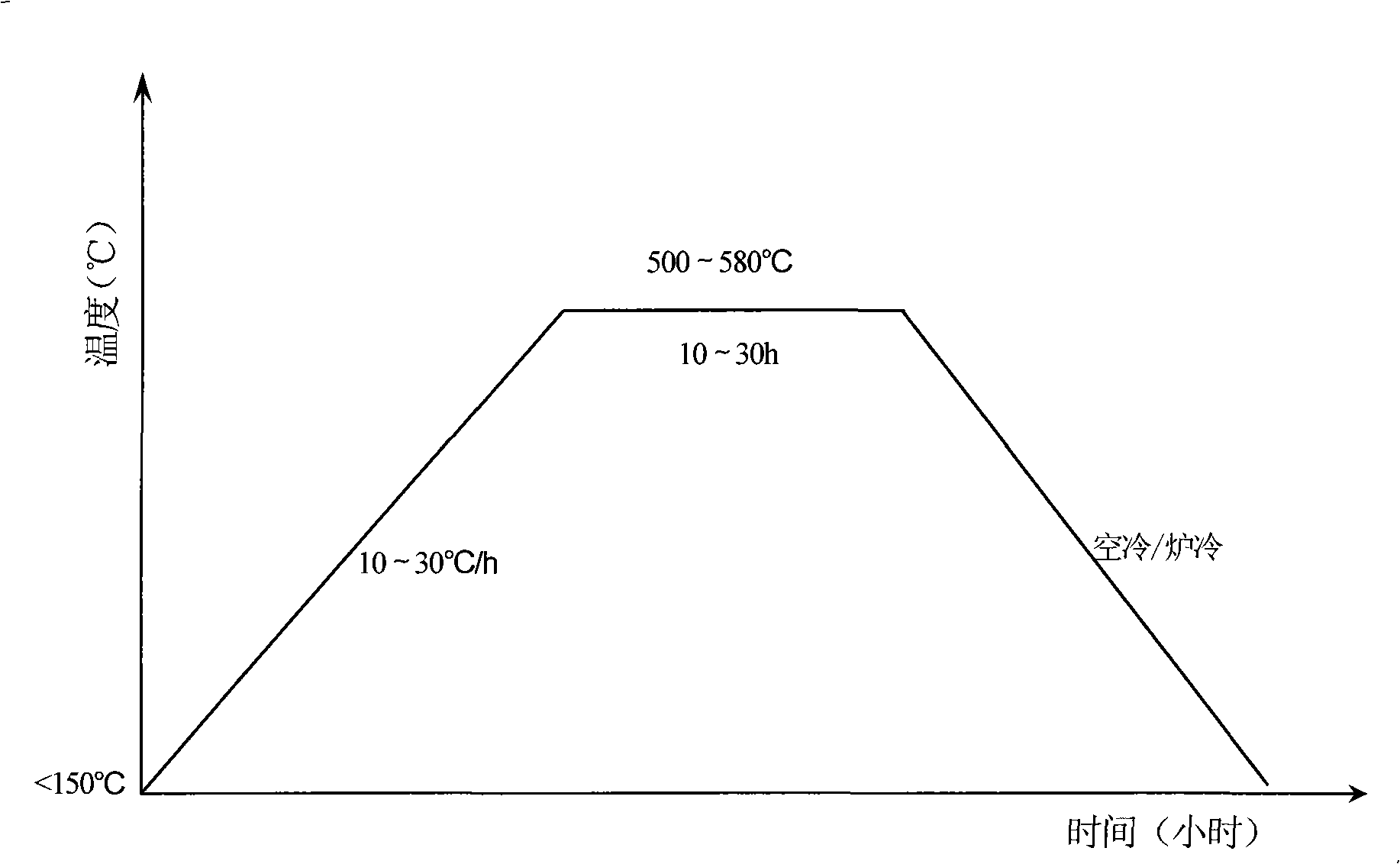

[0029] (3) Tempering

[0030] Heating rate for two temperings: 15°C / h; two tempering temperatures: 520°C; two tempering holding times: 15h.

[0031] The effect of this embodiment:

[00...

Embodiment 2

[0034] The trade mark of the high-speed steel of the present embodiment is 2C-6Mo-4Cr-6V, according to the heat treatment process of the high-speed steel composite roll of the present invention, the high-speed steel composite roll is heat-treated, adopting the following process parameters:

[0035] (1) Annealing

[0036] Annealing heating rate: 30°C / h; annealing heating temperature: 680°C; annealing holding time: 12h.

[0037] (2) Quenching

[0038] Heating rate in the initial stage of quenching: 20°C / h; primary holding temperature: 850°C; primary holding time: 8h; secondary heating rate in quenching: 80°C / h; austenitizing temperature: 1100°C; austenitizing time : 3h; quenching cooling method: air cooling; quenching furnace temperature: 450 ℃; furnace holding time: 5h.

[0039] (3) Tempering

[0040] Heating rate of two temperings: 25°C / h; two tempering temperatures: 530°C; two tempering holding times: 20h.

[0041] The effect of this embodiment:

[0042] Annealing hardne...

Embodiment 3

[0044] The trade mark of the high-speed steel of the present embodiment is 2.2C-W-5Mo-5Cr-6V, according to the heat treatment process of the high-speed steel composite roll of the present invention, the high-speed steel composite roll is heat-treated, adopting the following process parameters:

[0045] (1) Annealing

[0046] Annealing heating rate: 50°C / h; annealing heating temperature: 730°C; annealing holding time: 16h.

[0047] (2) Quenching

[0048] Heating rate in the initial stage of quenching: 25°C / h; primary holding temperature: 920°C; primary holding time: 12h; secondary heating rate in quenching: 100°C / h; austenitizing temperature: 1150°C; austenitizing time : 3h; quenching cooling method: air cooling + air cooling; quenching furnace temperature: 500 ℃; furnace holding time: 3h.

[0049] (3) Tempering

[0050] Heating rate for two temperings: 25°C / h; two tempering temperatures: 550°C; two tempering holding times: 25h.

[0051] The effect of this embodiment:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com